Operating industrial shredders in the Philippines requires strict adherence to safety protocols to protect workers and ensure efficient operations. As these powerful machines process materials ranging from plastic to metal, proper safety measures are essential to prevent accidents and maintain compliance with local regulations. This comprehensive guide outlines the critical safety standards for industrial shredder operation in the Philippines, with a focus on MAIKONG’s industry-leading safety features and best practices.

Need Expert Guidance on Industrial Shredder Safety?

Our specialists can help you select the right industrial shredder with advanced safety features for your specific application in the Philippines.

Contact Us on WhatsApp

Call us: 008613-51090-74-01

Philippine Regulatory Framework for Industrial Shredders

The Department of Labor and Employment (DOLE) in the Philippines establishes workplace safety guidelines that directly impact industrial shredder operations. These regulations are designed to protect workers from machinery hazards while ensuring efficient waste management and recycling processes.

Key Philippine Safety Regulations

- DOLE Occupational Safety and Health Standards (OSHS)

- Department of Environment and Natural Resources (DENR) guidelines for waste processing equipment

- Bureau of Philippine Standards (BPS) equipment certification requirements

- Local municipal permits for industrial machinery operation

- Noise regulation compliance (maximum 85dB for 8-hour shifts)

- Electrical safety standards for industrial equipment

- Emergency response protocols for industrial facilities

- Worker training certification requirements

MAIKONG’s plastic shredder machines are designed to meet and exceed these Philippine regulatory requirements, providing peace of mind for facility managers and safety officers.

Essential Personal Protective Equipment (PPE) for Shredder Operators

Proper PPE is the first line of defense when operating industrial shredders. In the Philippines, where industrial safety awareness continues to grow, ensuring operators have appropriate protective gear is essential for compliance and worker safety.

Head and Eye Protection

- Safety helmets with face shields

- Impact-resistant safety glasses

- Full-face protection for certain operations

Body Protection

- Cut-resistant coveralls

- High-visibility clothing

- Heat-resistant aprons for certain materials

Hand and Foot Protection

- Cut-resistant gloves

- Steel-toed safety boots

- Anti-slip footwear

Hearing Protection Standards

MAIKONG’s industrial plastic shredders are designed with noise reduction technology, but hearing protection remains essential. Philippine regulations require hearing protection when noise levels exceed 85 decibels over an 8-hour period.

- Earmuffs with minimum 25dB noise reduction rating

- Earplugs for supplementary protection

- Regular audiometric testing for operators

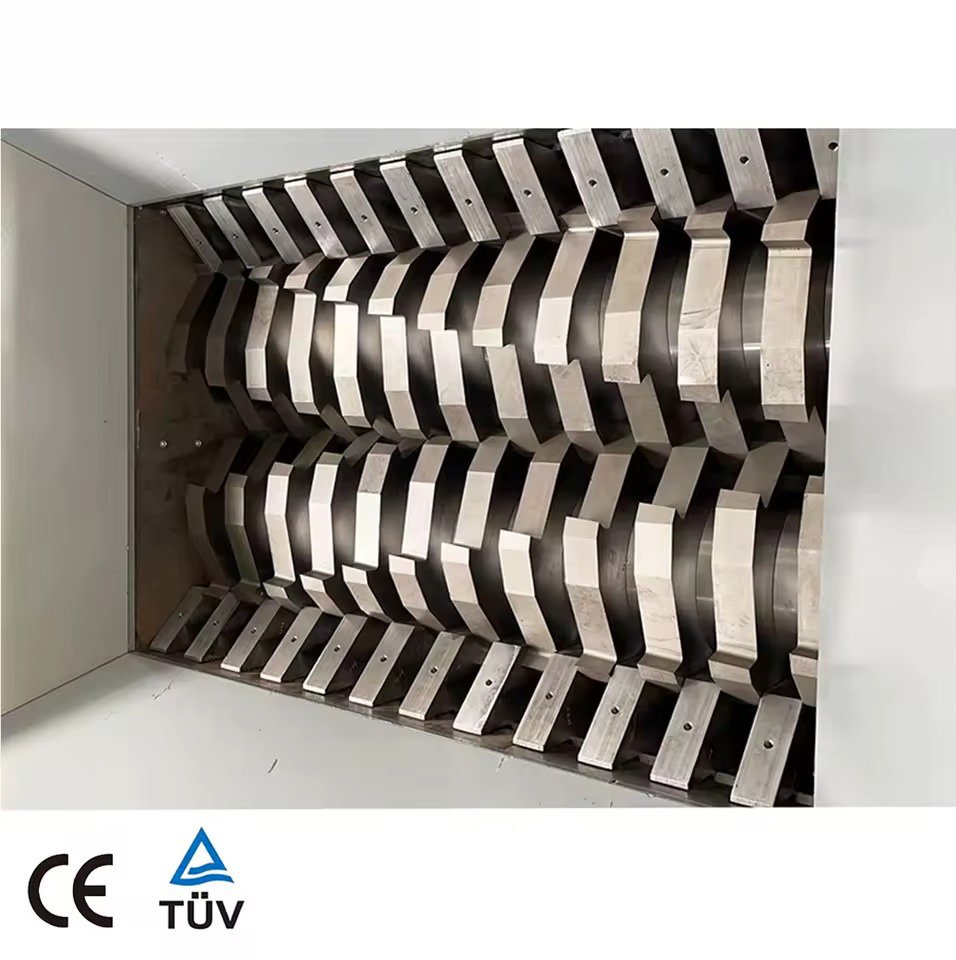

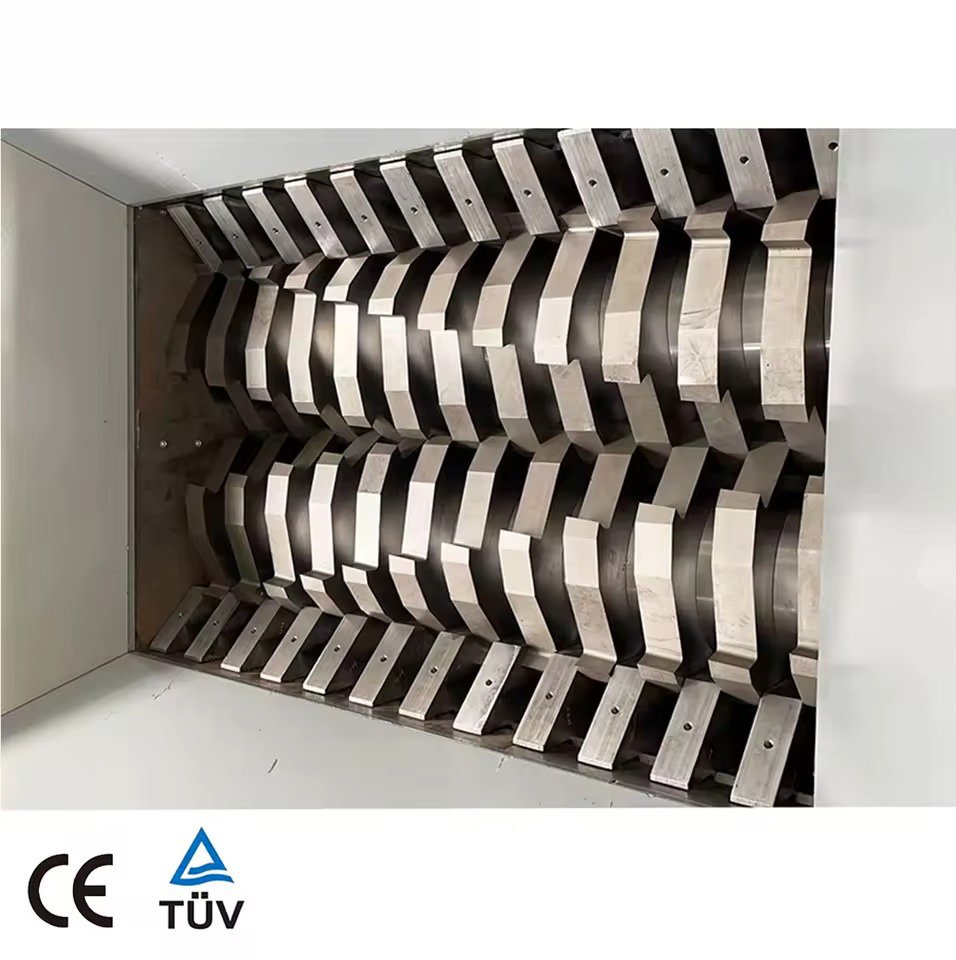

Essential Safety Features in MAIKONG Industrial Shredders

Modern industrial shredders incorporate numerous safety features designed to prevent accidents and protect operators. MAIKONG’s commitment to safety is evident in the comprehensive safety systems built into every machine.

Emergency Stop Systems

All MAIKONG plastic shredder machines feature multiple emergency stop buttons strategically positioned for quick access. These systems immediately halt all mechanical operations when activated.

- Prominent red emergency stop buttons

- Pull-cord emergency stops along machine perimeter

- Automatic shutdown during power fluctuations

Safety Interlocks

MAIKONG industrial plastic shredders incorporate comprehensive interlock systems that prevent operation when safety guards are removed or maintenance doors are open.

- Magnetic safety switches on access panels

- Keyed interlock systems for maintenance access

- Automatic shutdown when guards are removed

Overload Protection

To prevent mechanical failures and potential hazards, MAIKONG plastic shredders feature sophisticated overload protection systems that detect and respond to excessive material loads.

- Automatic reverse function when jammed

- Torque limiters to prevent mechanical damage

- Current monitoring with automatic shutdown

Advanced Safety Features in MAIKONG Mini Plastic Shredder Machines

Even MAIKONG’s smaller shredder models incorporate comprehensive safety systems suitable for Philippine operations:

- Low-speed, high-torque operation reduces risk of material ejection

- Automatic blade stopping within 3 seconds of power disconnection

- Hopper designs that prevent operator contact with cutting elements

- Transparent inspection windows with safety interlocks

Safe Operating Procedures for Industrial Shredders in the Philippines

Proper operational procedures are critical for preventing accidents when using industrial shredders. These guidelines are especially important in the Philippine context, where industrial safety awareness continues to develop.

Pre-Operation Safety Checklist

| Safety Check |

Procedure |

Frequency |

| Machine Perimeter |

Clear all obstructions within 2 meters of the shredder |

Before each use |

| Guards and Covers |

Verify all safety guards are securely in place |

Before each use |

| Emergency Stops |

Test all emergency stop buttons for proper function |

Daily |

| Material Inspection |

Check feed material for prohibited items (metals, stones) |

Before each batch |

| Electrical Connections |

Inspect power cables and connections for damage |

Weekly |

| Cutting Chamber |

Verify cutting chamber is empty before startup |

Before each use |

Safe Material Loading Procedures

Proper material loading is essential when operating MAIKONG plastic shredder machines to prevent jams and potential safety hazards:

- Ensure the machine is fully operational before loading materials

- Use appropriate material handling equipment (forklifts, conveyors) for large items

- Never exceed the manufacturer’s recommended feed rate

- Maintain a safe distance from the hopper during operation

- Never use hands or tools to push material into the cutting chamber

Emergency Response Procedures

Despite preventive measures, emergencies can occur. All operators of industrial shredders in the Philippines should be trained in these emergency procedures:

Machine Jams

- Activate emergency stop immediately

- Follow lockout/tagout procedure

- Wait for complete machine stoppage

- Use appropriate tools to clear jam

- Never reach into cutting chamber

Fire Response

- Activate emergency stop

- Alert all personnel

- Use appropriate fire extinguisher

- Evacuate if necessary

- Contact emergency services

Injury Response

- Stop the machine immediately

- Provide first aid as appropriate

- Contact emergency medical services

- Secure the area

- Document the incident

Enhance Your Operation with MAIKONG Safety-First Shredders

Our industrial plastic shredders are designed with operator safety as the top priority, meeting all Philippine regulatory requirements.

View Our Plastic Shredder Range

Call for expert advice: 008613-51090-74-01

Maintenance Safety for Industrial Shredders

Proper maintenance is crucial for both operational efficiency and safety when working with industrial shredders. MAIKONG recommends these safety-focused maintenance procedures for operations in the Philippines:

Lockout/Tagout Procedures

Lockout/Tagout (LOTO) procedures are essential safety practices that prevent unexpected energization or startup of machinery during maintenance:

- Notify all affected employees before beginning LOTO

- Shut down the machine using normal stopping procedure

- Disconnect all energy sources (electrical, hydraulic, pneumatic)

- Apply lockout devices to energy isolation points

- Verify zero energy state before beginning work

- Remove locks and tags only after work is complete

Safe Blade Maintenance

The cutting blades in plastic shredder machines require regular maintenance to ensure optimal performance and safety. MAIKONG’s plastic shredder parts are designed for safe and efficient maintenance:

Blade Inspection

- Check for wear, cracks, or damage

- Inspect blade mounting bolts for tightness

- Measure blade gaps according to specifications

- Document inspection results

Blade Replacement

- Use only manufacturer-approved parts

- Wear cut-resistant gloves

- Use proper lifting tools for heavy blades

- Follow torque specifications for fasteners

Lubrication Safety

- Use specified lubricants only

- Avoid over-lubrication

- Clean up spills immediately

- Dispose of used lubricants properly

Preventive Maintenance Schedule

MAIKONG recommends this preventive maintenance schedule for industrial shredders operating in the Philippines:

| Maintenance Task |

Frequency |

Safety Considerations |

| Blade inspection and rotation |

Every 80-100 operating hours |

Complete LOTO procedure, wear cut-resistant gloves |

| Bearing lubrication |

Monthly |

Machine powered down, wipe excess lubricant |

| Drive system inspection |

Quarterly |

Complete LOTO procedure, check guards after service |

| Electrical system check |

Quarterly |

Qualified electrician only, verify grounding |

| Hydraulic system service |

Semi-annually |

Relieve pressure before service, check for leaks |

| Complete blade replacement |

As needed (typically 500-1000 hours) |

Complete LOTO, use lifting aids, verify torque |

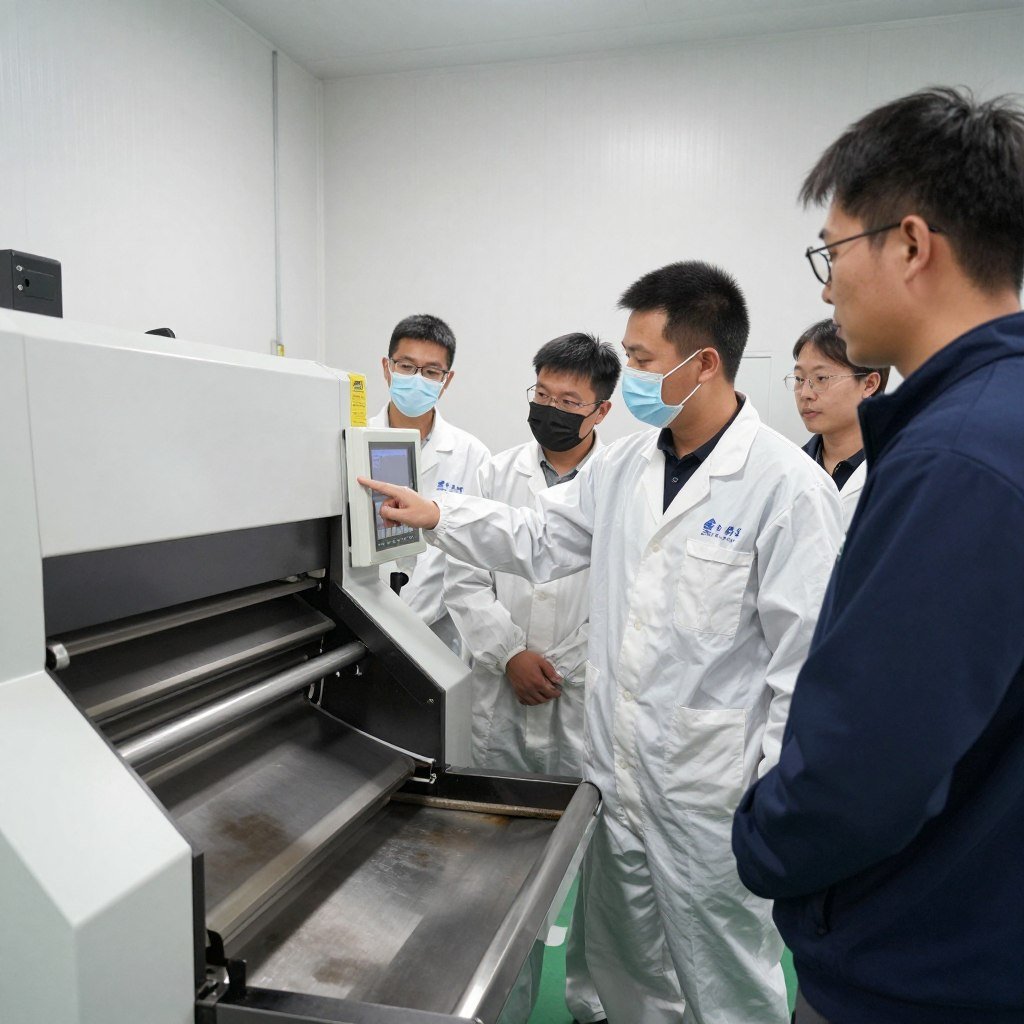

Operator Training Requirements for Industrial Shredders

Comprehensive operator training is essential for safe operation of industrial shredders in the Philippines. MAIKONG recommends these training components for all shredder operators:

Basic Training

- Machine familiarization

- Control systems operation

- Standard operating procedures

- Material handling techniques

- PPE requirements and usage

Safety Training

- Emergency stop procedures

- Hazard recognition

- Lockout/tagout procedures

- Emergency response

- First aid for common injuries

Advanced Training

- Troubleshooting procedures

- Basic maintenance tasks

- Material optimization

- Quality control procedures

- Documentation requirements

Training Documentation and Certification

In the Philippines, proper documentation of operator training is essential for regulatory compliance and liability protection. MAIKONG recommends maintaining these training records:

- Training attendance records with dates and topics

- Competency assessments for each operator

- Refresher training schedule and completion records

- Trainer qualifications and certifications

- Machine-specific training documentation

Safety Features in MAIKONG Industrial Shredder Models

MAIKONG offers a range of industrial shredders with model-specific safety features designed for various applications in the Philippines:

MAIKONG Industrial Plastic Shredder Safety Features

Our heavy-duty industrial models feature comprehensive safety systems:

- Low-speed, high-torque rotor design minimizes material ejection risk

- Dual-shaft cutting system with automatic reverse for jam prevention

- Reinforced hopper design prevents operator access to cutting zone

- Multiple emergency stop locations around the machine perimeter

- PLC control system with automatic overload protection

- Safety interlocks on all access panels and maintenance doors

MAIKONG Mini Plastic Shredder Machine Safety Features

Our compact models maintain high safety standards while offering space-efficient design:

- Enclosed cutting chamber with safety interlock

- Hopper design prevents hand access to cutting elements

- Single-button emergency stop within operator reach

- Automatic motor protection against overheating

- Stable base design prevents tipping during operation

- Low noise operation (below 85dB) for improved workplace safety

MAIKONG Small Plastic Shredder Safety Considerations

Even our smallest models incorporate essential safety features:

- Fully enclosed cutting chamber with viewing window

- Safety interlock prevents operation when chamber is open

- Automatic motor protection against overload

- Stable mounting options to prevent movement during operation

- Low voltage control circuit for operator safety

- Simplified maintenance access with safety interlocks

Risk Assessment for Industrial Shredder Operations

Conducting thorough risk assessments is essential for safe industrial shredder operation in the Philippines. MAIKONG recommends this systematic approach:

Hazard Identification

- Mechanical hazards (cutting, crushing, entanglement)

- Electrical hazards (shock, arc flash)

- Noise exposure hazards

- Material handling hazards

- Maintenance-related hazards

Risk Evaluation

- Assess likelihood of hazard occurrence

- Evaluate potential severity of injury

- Consider frequency of exposure

- Document existing control measures

- Identify risk gaps requiring attention

Control Implementation

- Engineering controls (guards, interlocks)

- Administrative controls (procedures, training)

- PPE requirements

- Emergency response planning

- Regular review and updating

Sample Risk Assessment Matrix

| Hazard |

Risk Level |

Control Measures |

| Hand contact with cutting blades |

High |

Safety interlocks, hopper design, PPE, training |

| Material ejection during shredding |

Medium |

Enclosed design, proper feed rate, face shields |

| Electrical hazards during maintenance |

High |

LOTO procedures, qualified personnel, insulated tools |

| Noise exposure |

Medium |

Hearing protection, engineering controls, rotation |

| Manual handling injuries |

Medium |

Mechanical aids, proper technique training, team lifting |

| Dust exposure |

Low-Medium |

Dust collection systems, respiratory protection, ventilation |

Conclusion: Prioritizing Safety in Industrial Shredder Operations

Safety is not optional when operating industrial shredders in the Philippines. By implementing comprehensive safety standards, businesses can protect their workers, comply with regulations, and optimize operational efficiency.

MAIKONG’s commitment to safety is evident in our comprehensive range of plastic shredder machines, industrial plastic shredders, and mini plastic shredder machines. Our products are designed with advanced safety features that meet and exceed Philippine regulatory requirements.

From proper PPE and machine-specific safety features to comprehensive operator training and regular maintenance, every aspect of shredder safety contributes to a safer, more productive workplace. By partnering with MAIKONG, Philippine businesses gain access to not only high-quality shredding equipment but also the expertise and support needed to implement best-in-class safety practices.

For more information about MAIKONG’s safety-focused industrial shredders or to schedule a safety consultation for your facility, contact our team today.

What are the most important safety features to look for in an industrial shredder for Philippine operations?

Key safety features include emergency stop systems, safety interlocks on access panels, overload protection, hopper designs that prevent operator access to cutting elements, and low-speed high-torque operation that minimizes material ejection. MAIKONG’s industrial shredders incorporate all these features and more to ensure operator safety in Philippine facilities.

How often should industrial shredder operators receive safety training?

Initial comprehensive training should be provided before an operator begins working with an industrial shredder. Refresher training should be conducted at least annually, with additional training whenever new equipment is installed or procedures are updated. MAIKONG recommends quarterly safety reviews to reinforce proper procedures and address any emerging concerns.

What Philippine regulations apply to industrial shredder operations?

Key regulations include the DOLE Occupational Safety and Health Standards (OSHS), DENR guidelines for waste processing equipment, and local municipal permits for industrial machinery operation. MAIKONG’s plastic shredder machines are designed to meet all applicable Philippine regulatory requirements, ensuring compliant operation.