In today’s competitive manufacturing environment, efficient waste management is no longer optional—it’s essential for operational efficiency, cost control, and environmental compliance. For plastic processing facilities in the Philippines, choosing between compact distributed shredders and Centralized Shredding Systems can significantly impact your bottom line. This comprehensive guide examines how MAIKONG’s innovative shredding solutions can transform your factory’s waste management approach, turning plastic waste from a liability into a valuable resource.

Centralized Shredding Systems vs. Compact Solutions

Before diving into the specifics, it’s important to understand what distinguishes these two approaches to plastic waste management in manufacturing environments.

Compact Distributed Shredding

Compact shredding systems are smaller units placed at multiple locations throughout a facility. These point-of-use shredders process waste at its source, typically handling lower volumes with less power. While they offer convenience, they present challenges in maintenance, consistency, and overall efficiency.

Centralized Shredding Systems

A centralized approach consolidates all shredding operations into a single, high-capacity system. MAIKONG’s Centralized Shredding Systems feature industrial-grade equipment designed to handle large volumes efficiently. This approach streamlines waste management, improves quality control, and maximizes recycling potential.

Common Plastic Waste Challenges in Philippine Factories

Manufacturing facilities across the Philippines face unique challenges when managing plastic waste. Understanding these challenges is crucial for selecting the right shredding solution.

Key Waste Management Goals

- Reducing disposal costs and environmental impact

- Reclaiming valuable materials for reuse

- Maintaining efficient production workflows

- Meeting regulatory compliance requirements

- Maximizing floor space utilization

Common Waste Management Challenges

- High volumes of mixed plastic waste types

- Inconsistent shredding quality with multiple machines

- Maintenance and downtime of multiple units

- Transportation of waste between processing areas

- Space constraints in production environments

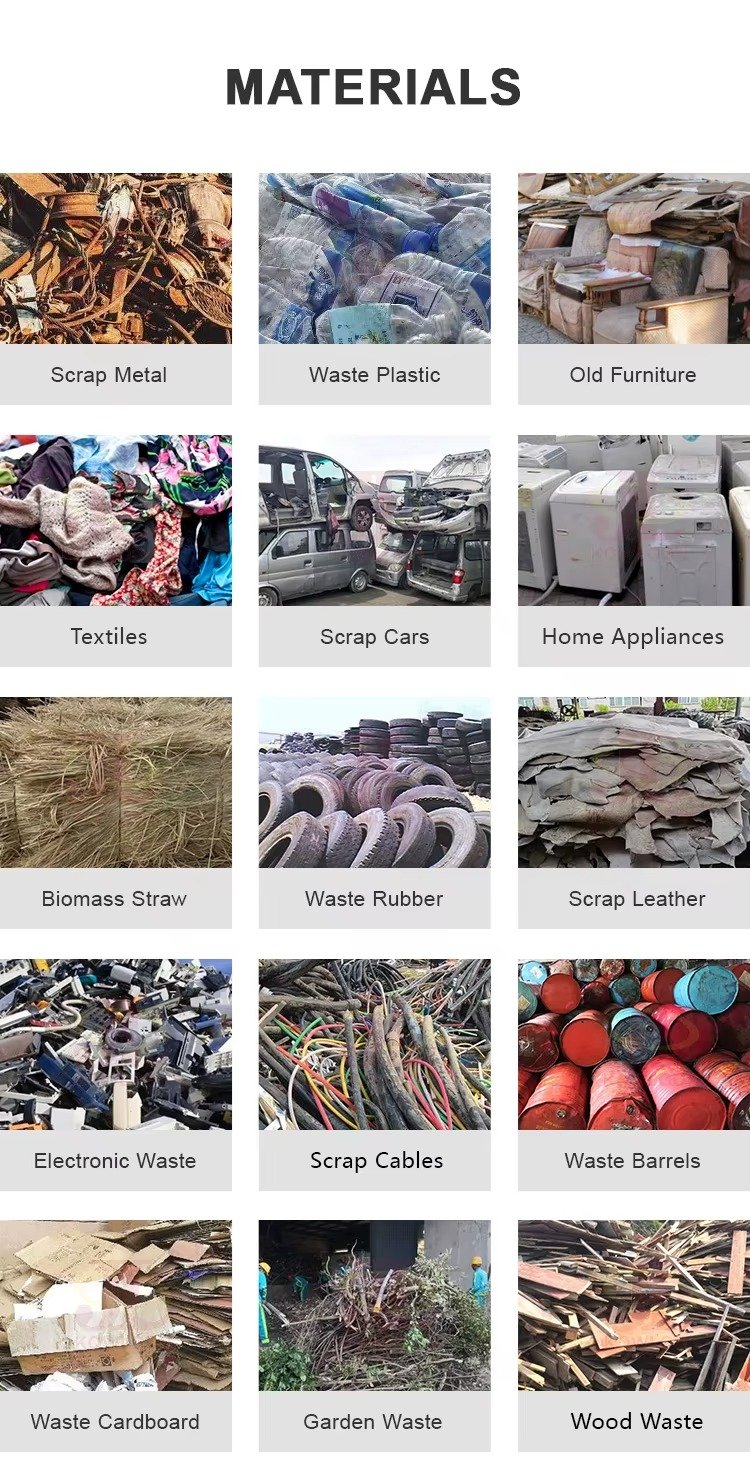

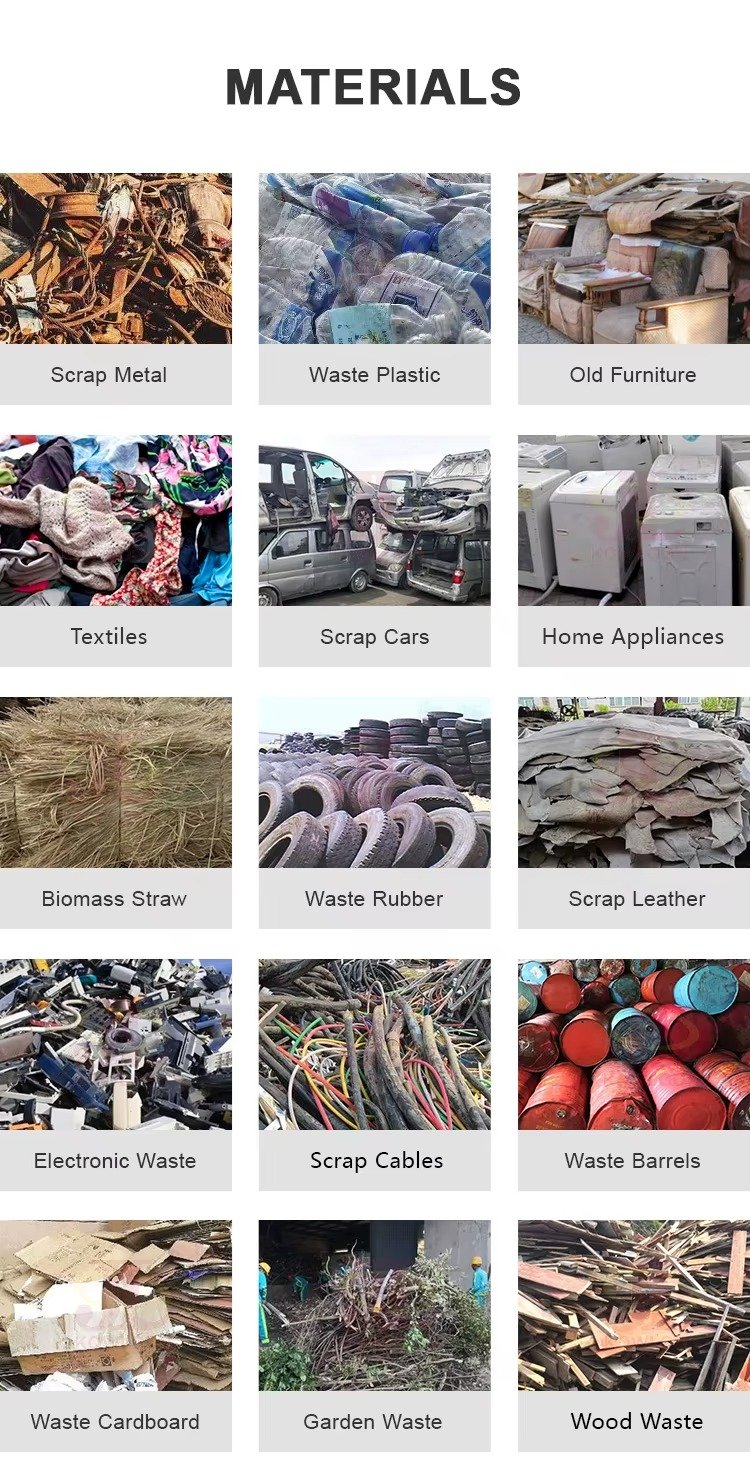

Types of Plastic Waste in Manufacturing

| Waste Type |

Source |

Characteristics |

Shredding Challenges |

| Injection Molding Purges |

Mold changes, color transitions |

Dense, irregular shapes |

High torque requirements |

| Extrusion Lumps |

Production startups, shutdowns |

Thick, varied consistency |

Size reduction difficulties |

| Blow Molding Waste |

Trimming operations |

Thin walls, hollow forms |

Feeding consistency |

| Thermoforming Scrap |

Sheet trimming, rejected parts |

Thin, sometimes brittle |

Volume-to-weight ratio |

| Runners and Sprues |

Injection molding |

Hard, varied shapes |

Wear on cutting blades |

Why Centralized Shredding Systems Outperform Compact Solutions

When comparing Centralized Shredding Systems to distributed compact shredders, several key advantages become apparent for factory environments:

Economic Benefits

- Lower total investment than multiple compact units

- Reduced maintenance costs with single system upkeep

- Lower power consumption per kilogram processed

- Increased material recovery value through consistent processing

- Reduced labor requirements for operation and oversight

Operational Advantages

- Higher throughput capacity for large volume processing

- Consistent particle size for better recycling quality

- Centralized quality control and monitoring

- Simplified material collection and handling

- Reduced production floor disruption

Technical Superiority

- Higher torque capabilities for challenging materials

- Advanced cutting technology for precision shredding

- Integrated feeding and discharge systems

- Sophisticated control systems for process optimization

- Adaptability to various material types

“Implementing MAIKONG’s Centralized Shredding System allowed us to reduce our plastic waste processing costs by 37% while improving our recycling quality. The system paid for itself within 14 months.”

– Production Manager, Philippine Packaging Manufacturer

MAIKONG’s Centralized Shredding Systems for Philippine Factories

MAIKONG offers a comprehensive range of Centralized Shredding Systems specifically designed for the needs of Philippine manufacturing facilities. Our solutions combine robust engineering, energy efficiency, and operational flexibility.

Core Components of MAIKONG Centralized Shredding Systems

- High-Torque Cutting Chamber: Engineered with special alloy blades for handling diverse plastic waste types, from thin films to thick purges.

- Intelligent Feed System: Automatically adjusts to material density and volume, preventing jams and optimizing throughput.

- Precision Control System: PLC-based controls with automatic reverse for overload protection, minimizing downtime and blade damage.

- Integrated Collection System: Efficient material handling from input to output, with options for direct connection to bagging or pelletizing systems.

- Energy Management Technology: Reduces power consumption during idle periods while maintaining rapid response capabilities.

MAIKONG’s specialized cutting chamber with heat-treated alloy blades

Popular MAIKONG Centralized Shredding Systems Models

| Model |

Blade Diameter |

Motor Power |

Throughput Capacity |

Ideal Applications |

| MAIKONG 800 |

300mm |

18.5kW×2-22kW×2 |

500-800 kg/hr |

Medium-sized injection molding facilities |

| MAIKONG 1000 |

400mm |

45kW×2 |

800-1200 kg/hr |

Large extrusion and blow molding operations |

| MAIKONG 1400 |

500mm |

55kW×2 |

1200-1800 kg/hr |

Centralized recycling for multiple production lines |

| MAIKONG 1600 |

500mm |

75kW×2 |

1800-2500 kg/hr |

High-volume plastic manufacturing facilities |

Customization Options for Your Centralized Shredding System

Every manufacturing facility has unique requirements. MAIKONG offers extensive customization options to tailor your Centralized Shredding System to your specific needs:

Input Systems

- Belt Conveyors: For continuous feeding of mixed materials

- Screw Conveyors: Ideal for controlled feeding of smaller items

- Inclined Chutes: Facilitates forklift or crane loading

- Vertical Ram Feeders: Forces difficult materials into cutting chamber

- Hopper Extensions: Increases loading capacity

Processing Enhancements

- Specialized Rotors: Optimized for specific material types

- Upgraded Motors: For higher throughput requirements

- Hydraulic Drive Systems: For extreme torque applications

- Enlarged Cutting Chambers: For oversized materials

- Screen Customization: Controls output particle size

Output Solutions

- Cyclone Collection: For lightweight materials

- Output Conveyors: Directs processed material

- Bagging Systems: Automatic collection in bags or containers

- Integration with Granulators: For further size reduction

- Direct Feed to Pelletizing: For closed-loop recycling

Custom MAIKONG Centralized Shredding System configured for a Philippine plastic manufacturing facility

Custom Solutions for Your Unique Challenges

MAIKONG’s engineering team can design a Centralized Shredding System specifically for your factory’s requirements, waste types, and space constraints.

Request Custom Configuration

Implementing a Centralized Shredding System in Your Factory

Transitioning from distributed compact shredders to a MAIKONG Centralized Shredding System is a straightforward process with our comprehensive support:

1. Assessment and Planning

Our experts conduct a thorough analysis of your current waste management processes, material types, volumes, and facility layout. We develop a detailed implementation plan that minimizes disruption to your operations while maximizing efficiency gains.

2. System Design and Configuration

Based on the assessment, we configure a Centralized Shredding System tailored to your specific requirements. This includes selecting the appropriate model, customizing input and output systems, and integrating with your existing processes.

3. Installation and Setup

MAIKONG’s technical team handles the complete installation process, from site preparation to final setup. We ensure all components are properly integrated and functioning according to specifications.

4. Training and Handover

We provide comprehensive training for your operators and maintenance personnel, ensuring they understand how to maximize the efficiency and lifespan of your new system. Detailed documentation and operating manuals are provided.

5. Ongoing Support and Maintenance

MAIKONG offers responsive technical support and maintenance services throughout the lifecycle of your Centralized Shredding System. Regular maintenance plans ensure optimal performance and longevity.

Implementation Timeline

A typical MAIKONG Centralized Shredding System can be fully operational within 4-6 weeks from order confirmation, depending on customization requirements and site preparation needs.

Return on Investment Analysis

Investing in a MAIKONG Centralized Shredding System delivers measurable financial benefits compared to distributed compact shredders:

| Cost Factor |

Multiple Compact Shredders |

MAIKONG Centralized System |

Typical Savings |

| Initial Equipment Investment |

Higher total cost for equivalent capacity |

Lower cost per kg processed |

20-30% |

| Energy Consumption |

Less efficient with multiple motors |

Optimized power usage |

15-25% |

| Maintenance Costs |

Multiple service points and parts |

Consolidated maintenance |

30-40% |

| Labor Requirements |

Multiple operators and oversight |

Single point of operation |

40-60% |

| Material Recovery Value |

Inconsistent quality |

Higher quality regrind |

10-20% increase |

| Floor Space Utilization |

Distributed footprint |

Optimized layout |

Variable |

Typical Payback Period

Most Philippine factories implementing MAIKONG Centralized Shredding Systems achieve complete return on investment within 12-18 months, depending on waste volumes and current processing costs.

Success Stories: Centralized Shredding Systems in Action

See how Philippine manufacturers have benefited from implementing MAIKONG Centralized Shredding Systems:

Packaging Manufacturer in Manila

Challenge: Managing waste from 12 injection molding lines with five separate compact shredders, resulting in inconsistent regrind quality and high maintenance costs.

Solution: Implemented MAIKONG 1400 Centralized Shredding System with custom infeed conveyor system.

Results:

- 42% reduction in energy costs per kg processed

- 65% decrease in maintenance expenses

- Improved regrind quality allowing 30% higher recycled content in products

- ROI achieved in 11 months

Bottle Manufacturer in Cebu

Challenge: High volumes of blow molding scrap with inconsistent processing using distributed shredders, creating production bottlenecks.

Solution: MAIKONG 1000 Centralized Shredding System with specialized rotor design for hollow forms.

Results:

- Throughput increased by 75% compared to previous system

- Labor costs reduced by 50% for waste handling

- Floor space reclaimed by eliminating multiple shredding stations

- Consistent particle size improved downstream processing

Parts and Maintenance for Long-Term Performance

MAIKONG ensures the longevity and optimal performance of your Centralized Shredding System with comprehensive parts and maintenance support:

Genuine MAIKONG Parts

- Cutting Blades: Precision-engineered from special alloy steel with heat treatment for optimal hardness and wear resistance

- Screens and Sieves: Available in various sizes to control output particle dimensions

- Drive Components: High-quality bearings, couplings, and transmission parts

- Electrical Components: Control system parts and sensors from leading manufacturers

- Hydraulic System Parts: Pumps, valves, and cylinders for systems with hydraulic components

All genuine MAIKONG plastic shredder parts are manufactured to strict quality standards, ensuring optimal performance and longevity.

Maintenance Programs

- Preventive Maintenance Plans: Scheduled service to prevent downtime and extend equipment life

- Technical Support: Rapid response troubleshooting via phone, email, or WhatsApp

- On-Site Service: Factory-trained technicians available for complex maintenance needs

- Operator Training: Ongoing education for new staff and skill enhancement

- Performance Optimization: Regular system evaluations to ensure peak efficiency

Our maintenance programs are designed to maximize uptime and performance while minimizing total cost of ownership.

Ensure Peak Performance

Keep your Centralized Shredding System running at optimal efficiency with genuine MAIKONG parts and expert maintenance.

Browse Shredder Parts

Transform Your Factory’s Waste Management Today

The choice between compact distributed shredders and a Centralized Shredding System significantly impacts your factory’s operational efficiency, costs, and environmental footprint. MAIKONG’s innovative Centralized Shredding Systems offer Philippine manufacturers a proven solution for transforming plastic waste management from a cost center into a value-adding process.

From our mini plastic shredder machines to our industrial-scale Centralized Shredding Systems, MAIKONG offers solutions for every size of operation. Our engineering expertise, quality manufacturing, and dedicated support ensure your investment delivers maximum returns.

Ready to explore how a MAIKONG Centralized Shredding System can benefit your factory? Contact our team today for a personalized consultation and solution proposal.

Take the Next Step

Contact MAIKONG today to discuss your factory’s specific needs and discover the ideal Centralized Shredding System solution.