The challenge of processing hard plastics like ABS computer shells and electronic waste continues to grow in the Philippines. These rigid materials resist conventional recycling methods, requiring specialized equipment and techniques to process effectively. As e-waste volumes increase yearly, businesses need reliable solutions to shred hard plastics efficiently while maximizing material recovery and profitability.At MAIKONG, we’ve developed advanced technology specifically designed to tackle the toughest plastic materials. Our expertise in hard plastic shredding has helped countless businesses transform waste management challenges into profitable recycling operations. This comprehensive guide will walk you through everything you need to know about effectively processing ABS, polycarbonate, and other rigid plastics.

The Challenge of Shredding Hard Plastics

Not all plastics are created equal. When it comes to shredding hard plastics like ABS computer shells, standard equipment often falls short. These materials present unique challenges that require specialized solutions.

ABS computer shells and e-waste components present significant recycling challenges due to their rigidity and composition

Why ABS and E-Waste Are Difficult to Process

ABS (Acrylonitrile Butadiene Styrene) plastic, commonly used in computer shells, presents several challenges:

- Exceptional hardness and impact resistance

- High melting point (approximately 105°C)

- Tendency to dull standard shredder blades quickly

- Often contains flame retardants and other additives

- Frequently combined with metal components in e-waste

These properties make shredding hard plastics like ABS particularly challenging. Standard plastic shredders often jam, overheat, or experience rapid blade wear when processing these materials. The result? Increased downtime, higher maintenance costs, and reduced productivity.

Common Problems with Inadequate Shredders

Proper Hard Plastic Shredding

- Consistent particle size for efficient recycling

- Minimal dust generation

- Lower energy consumption

- Reduced noise and vibration

- Longer equipment lifespan

Inadequate Shredding Equipment

- Frequent jams and downtime

- Inconsistent output size

- Excessive heat generation

- Rapid blade wear and damage

- Higher operating costs

Businesses in the Philippines often struggle with these challenges when attempting to recycle computer shells and electronic waste. The good news? With the right equipment and techniques, shredding hard plastics can be both efficient and profitable.

MAIKONG’s Solutions for Shredding Hard Plastics

Successfully shredding hard plastics requires equipment specifically designed for these challenging materials. MAIKONG offers a comprehensive range of shredders engineered to handle ABS computer shells, e-waste, and other rigid plastics efficiently.

MAIKONG industrial plastic shredder efficiently processing ABS computer shells

Industrial Plastic Shredders for Bulk Processing

For large-scale operations handling significant volumes of e-waste and computer shells, our industrial plastic shredder models deliver exceptional performance:

Double-Shaft Shredder Technology

Our heavy-duty double-shaft shredders are specifically designed for shredding hard plastics like ABS. Key features include:

- Dual counter-rotating shafts with hardened steel blades

- High-torque, low-speed operation to prevent overheating

- Automatic reverse function for jam prevention

- Adjustable cutting gap for optimal processing

- Reinforced drive system for continuous operation

These industrial units excel at processing large volumes of ABS computer shells, housing components, and mixed e-waste. The robust design ensures consistent operation even when dealing with the toughest materials.

Small & Mini Shredders for Specific Applications

Not every operation requires industrial-scale equipment. For smaller businesses or specialized applications, MAIKONG offers compact solutions that don’t compromise on performance:

Small Plastic Shredder

Perfect for medium-volume operations or businesses with space constraints, our small plastic shredder models offer:

- Compact footprint with robust performance

- Specialized blade configuration for hard plastics

- Output size control for precise results

- Energy-efficient operation

Inquire via WhatsApp

Mini Plastic Shredder Machine

Ideal for small workshops, laboratories, or pilot projects, our mini plastic shredder machine delivers:

- Exceptional mobility and versatility

- Surprisingly powerful performance for its size

- Perfect for processing smaller batches

- Low maintenance requirements

Email for Mini Shredder Details

These smaller units maintain the same quality standards and specialized features needed for effectively shredding hard plastics, just in a more compact package.

Technical Requirements for Shredding Hard Plastics

Successfully processing ABS computer shells and e-waste requires understanding the technical aspects that make shredding hard plastics different from other materials.

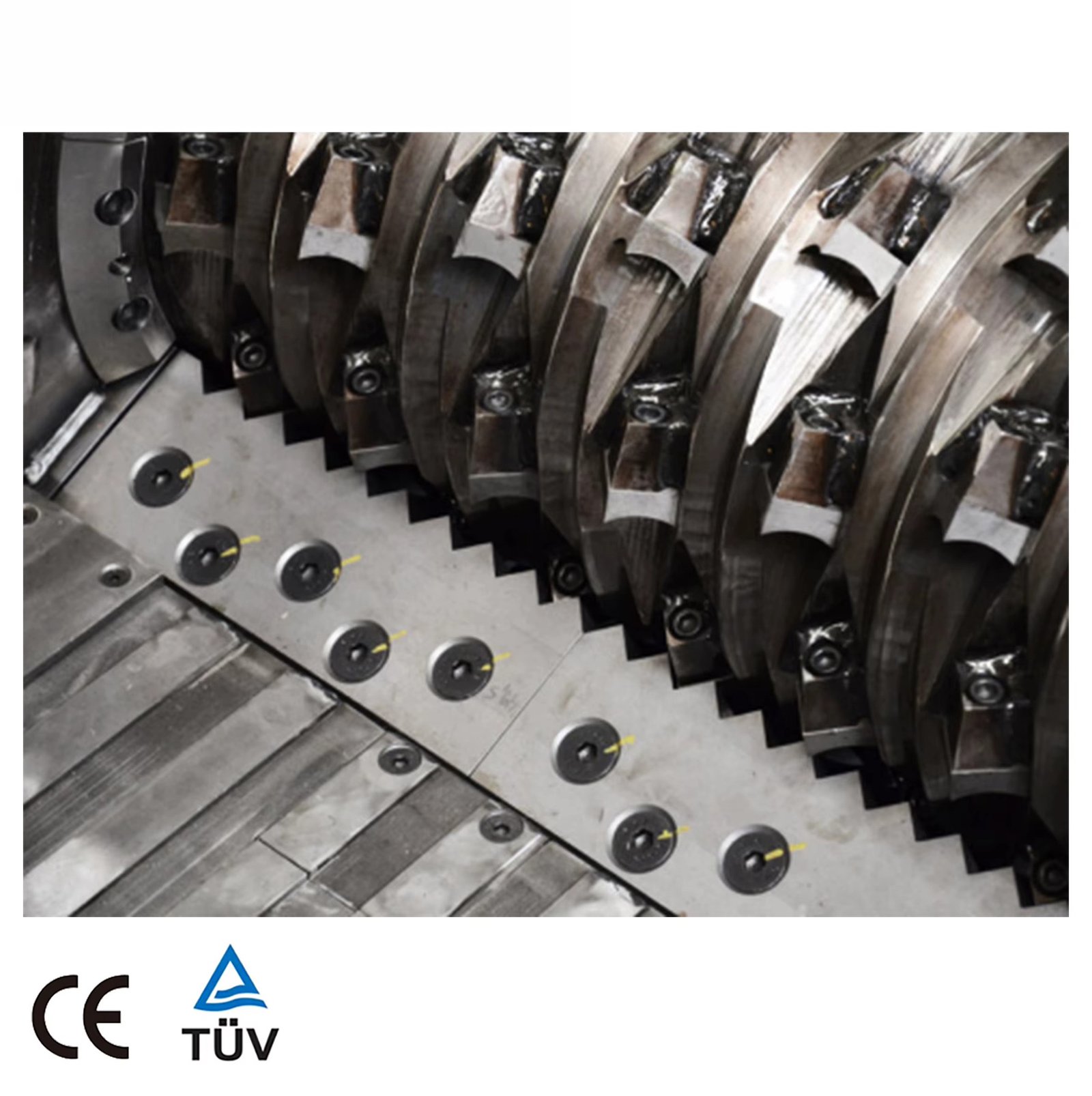

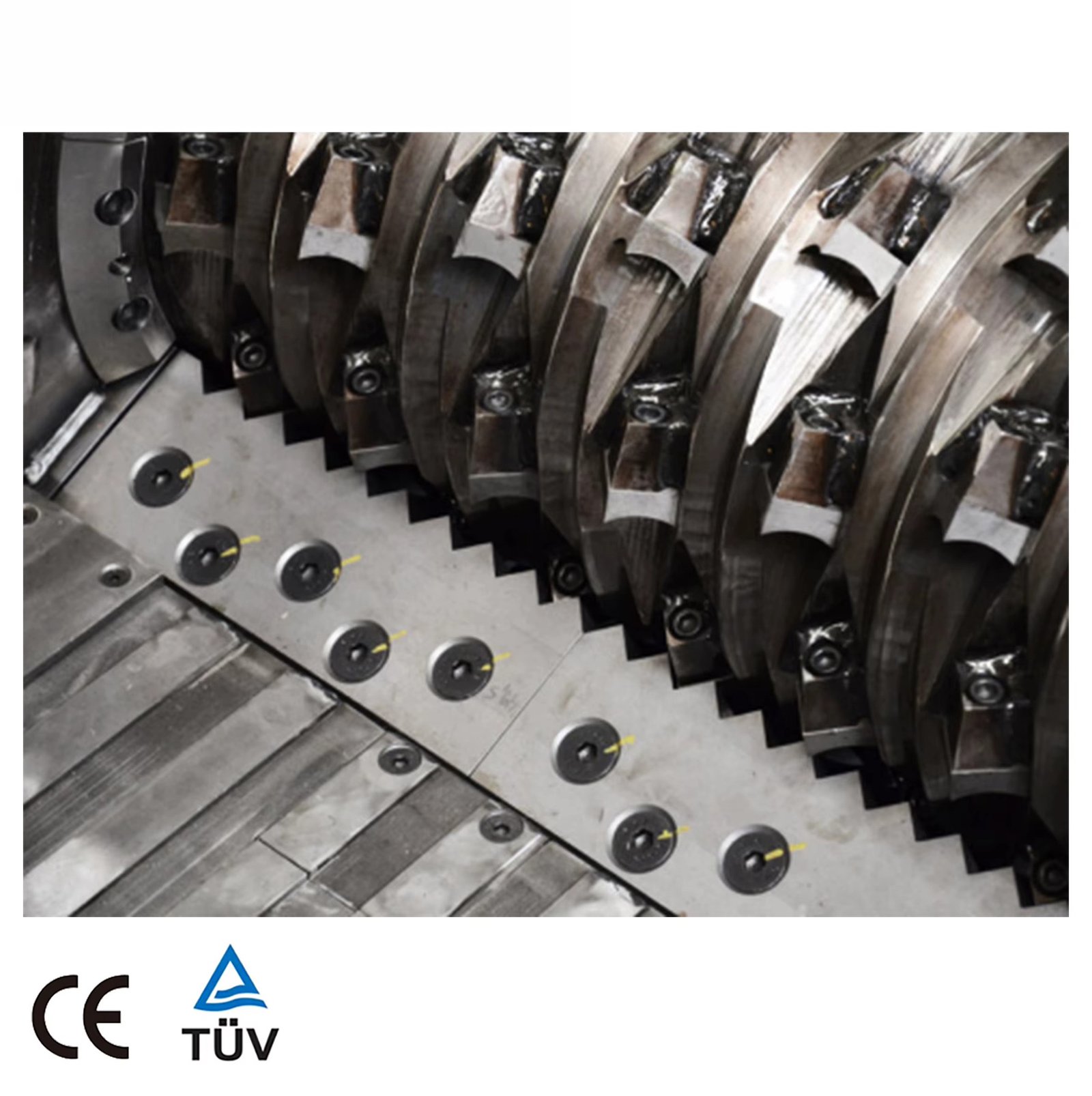

Specialized hardened steel blades designed specifically for shredding ABS and other rigid plastics

Blade Technology and Materials

The heart of any system for shredding hard plastics is the blade technology. MAIKONG utilizes several specialized approaches:

| Blade Type |

Material |

Advantages for Hard Plastics |

Recommended Application |

| Standard Hardened Steel |

D2 Tool Steel |

Good balance of hardness and toughness |

General ABS processing |

| Tungsten Carbide-Tipped |

Steel with carbide inserts |

Extended life, maintains sharp edge |

High-volume operations |

| Serrated Edge |

Special alloy steel |

Better grip on smooth surfaces |

Computer shells, smooth plastics |

| Staggered Configuration |

Varies |

Prevents material slippage |

Mixed e-waste |

MAIKONG’s plastic shredder parts, especially our blades, are engineered specifically for the challenges of shredding hard plastics.

Drive Systems and Power Requirements

Processing rigid materials like ABS requires significant torque. Our shredders feature:

- High-torque, low-speed motors to maximize cutting force

- Reinforced gearboxes designed for continuous operation

- Hydraulic drive options for the toughest applications

- Energy-efficient designs that reduce operating costs

- Automatic load sensing to adjust power consumption

Technical diagram of MAIKONG’s specialized drive system designed for the high torque needed when shredding hard plastics

Screen Size and Output Control

The final particle size is critical for downstream processing. MAIKONG shredders offer:

Customizable Output Options

Different applications require different output sizes. Our machines feature:

- Interchangeable screens for precise size control

- Options ranging from 8mm to 50mm

- Specialized screen designs to prevent clogging

- Optimized screen patterns for hard plastics

The right screen selection ensures optimal performance when shredding hard plastics, balancing throughput with the desired particle size.

The Business Case for Shredding Hard Plastics in the Philippines

Beyond the technical aspects, there’s a compelling business case for investing in equipment capable of effectively shredding hard plastics in the Philippines.

Modern Philippine recycling facility processing ABS computer shells with MAIKONG equipment

The Growing E-Waste Challenge

The Philippines faces a mounting e-waste crisis:

- Over 3 million tons of e-waste generated annually

- Computer equipment represents approximately 20% of this volume

- ABS and other hard plastics constitute up to 30% of computer waste

- Current recycling infrastructure processes less than 15% of available material

- Regulations increasingly restrict improper disposal

This creates a significant opportunity for businesses equipped to properly shred hard plastics from e-waste streams.

Economic Benefits of Proper Processing

Material Recovery Value

4.6/5

Operational Efficiency

4.8/5

Regulatory Compliance

4.7/5

Properly processed ABS and other hard plastics command premium prices in recycling markets. With MAIKONG equipment, businesses can:

- Achieve higher material recovery rates

- Produce consistent, high-quality recyclate

- Reduce processing costs through efficient operation

- Meet regulatory requirements for proper e-waste handling

- Create new revenue streams from previously problematic materials

Processed ABS plastic granules after shredding with MAIKONG equipment, ready for recycling into new products

The investment in quality equipment for shredding hard plastics typically pays for itself within 12-18 months through increased processing efficiency and higher-value output.

How to Choose the Right Shredder for Hard Plastics

Selecting the optimal equipment for shredding hard plastics requires careful consideration of several factors.

Comparison of MAIKONG shredder models optimized for different scales of hard plastic processing

Assessment Criteria for Your Operation

Consider these key factors when selecting a shredder for ABS and e-waste:

| Factor |

Considerations |

MAIKONG Recommendation |

| Volume |

Daily/monthly processing requirements |

Industrial models for >500kg/day, Small/Mini for lower volumes |

| Material Mix |

Pure ABS vs. mixed e-waste |

Double-shaft for mixed materials, Single-shaft for uniform input |

| Output Requirements |

Desired particle size and consistency |

Customizable screen options from 8-50mm |

| Space Constraints |

Available installation area |

Compact designs available for limited spaces |

| Budget |

Initial investment vs. operating costs |

Financing options and ROI analysis available |

Our team can help you assess these factors to determine the optimal configuration for your specific needs when shredding hard plastics.

Recommended Configurations for Philippine Operations

Based on our experience in the Philippine market, we typically recommend:

For Large Recycling Operations

Our industrial double-shaft shredders with 45-75kW motors, equipped with tungsten carbide-tipped blades and 15mm screens. This configuration handles mixed e-waste efficiently while producing consistent output suitable for further processing or direct sale.

For Medium-Sized Processors

Small to mid-sized shredders with 22-37kW motors and specialized blade configurations for hard plastics. These units balance throughput with energy efficiency and are ideal for operations processing 200-500kg daily.

For Small Workshops and Startups

Our mini shredders provide an excellent entry point, with 11-15kW motors that can still effectively process ABS and other hard plastics. These units offer the same quality construction in a more affordable, space-efficient package.

MAIKONG technician demonstrating proper feeding technique for hard plastics to ensure optimal shredding performance

Each configuration is optimized specifically for the challenges of shredding hard plastics like ABS computer shells and e-waste components.

Become a MAIKONG Distributor in the Philippines

The growing demand for equipment capable of effectively shredding hard plastics presents a significant business opportunity in the Philippines. MAIKONG is actively seeking distribution partners to expand our presence in this dynamic market.

MAIKONG representatives meeting with Philippine recycling business owners to discuss hard plastic shredding solutions

Why Partner with MAIKONG?

As a MAIKONG distributor, you’ll gain access to:

Product Advantages

- Industry-leading technology specifically designed for hard plastics

- Comprehensive product range from mini to industrial scale

- Proven reliability in demanding applications

- Competitive pricing with strong margins

- Continuous innovation and product development

Partnership Benefits

- Exclusive territorial rights

- Comprehensive technical training

- Marketing and sales support

- Spare parts inventory assistance

- Joint customer demonstrations and trials

Our distributors benefit from MAIKONG’s decades of experience in developing specialized solutions for shredding hard plastics and other challenging materials.

Ready to Explore Distribution Opportunities?

Contact our partnership team today to discuss becoming a MAIKONG distributor in the Philippines. We’re looking for motivated partners who understand the local market and are committed to providing exceptional service.

Become a Distributor

Conclusion: Mastering Hard Plastic Shredding

Successfully shredding hard plastics like ABS computer shells and e-waste requires specialized equipment, technical knowledge, and ongoing support. MAIKONG delivers all three, with solutions tailored to the unique needs of the Philippine market.

The complete recycling journey: From waste ABS computer shells to valuable recycled material with MAIKONG shredding technology

Whether you’re operating a large recycling facility or a small workshop, our range of plastic shredder machines offers the perfect solution for your hard plastic processing needs. With MAIKONG equipment, you can transform challenging waste streams into valuable resources while contributing to a more sustainable future for the Philippines.

Ready to learn more? Contact us today to discuss your specific requirements or to arrange a demonstration of our equipment in action. Our team is standing by to help you master the art of shredding hard plastics.

Contact MAIKONG Today

For more information about our solutions for shredding hard plastics or to discuss distribution opportunities in the Philippines: