The growing challenge of plastic waste management has placed industries across the Philippines at a crossroads. With landfills reaching capacity and environmental regulations tightening, shredding plastic pallets has emerged as a critical solution for businesses seeking sustainable waste management practices. MAIKONG’s advanced plastic shredder technology transforms bulky plastic pallets and crates into valuable recyclable material, creating economic opportunities while addressing environmental concerns.

The Growing Challenge of Plastic Pallet Waste

Plastic pallet waste presents significant disposal challenges for businesses

Plastic pallets and crates have become ubiquitous in supply chains across the Philippines due to their durability, lightweight properties, and resistance to moisture. However, this durability becomes problematic at the end of their useful life. Unlike wooden pallets, plastic variants don’t biodegrade, creating significant waste management challenges:

- A typical plastic pallet weighs between 15-25kg and occupies substantial landfill space

- The Philippines generates approximately 2.7 million tons of plastic waste annually

- Disposal costs continue to rise as landfill availability decreases

- Unprocessed plastic pallets can take over 400 years to decompose

- Environmental regulations increasingly restrict plastic waste disposal

For businesses handling large volumes of plastic pallets, the financial impact is substantial. Disposal fees, transportation costs, and potential regulatory penalties create a significant burden. However, these same challenges present an opportunity for forward-thinking companies willing to invest in plastic shredding technology.

The Solution: Shredding Plastic Pallets for Recycling

Shredding plastic pallets is the crucial first step in the recycling process, reducing bulky items into manageable pieces that can be efficiently processed further. This volume reduction offers immediate benefits:

Economic Benefits

- Reduced waste disposal costs

- Lower transportation expenses

- Potential revenue from selling processed material

- Tax incentives for recycling initiatives

Environmental Benefits

- Significant landfill diversion

- Reduced carbon footprint

- Conservation of raw materials

- Compliance with environmental regulations

The process begins with a primary plastic shredder machine that can handle whole pallets, reducing them to fragments typically 40-50mm in size. These fragments can then be further processed through granulation to achieve the particle size required for recycling or manufacturing new products.

Ready to Start Recycling Your Plastic Pallets?

MAIKONG offers customized shredding solutions for businesses of all sizes in the Philippines.

Get a Free Consultation

The Complete Process of Shredding Plastic Pallets

1. Collection and Sorting

The recycling process begins with collecting end-of-life plastic pallets and crates. These are typically sorted by plastic type, as different polymers require specific processing parameters. Most plastic pallets are made from HDPE (High-Density Polyethylene) or PP (Polypropylene), both of which are highly recyclable materials.

2. Primary Shredding with Industrial Plastic Shredder

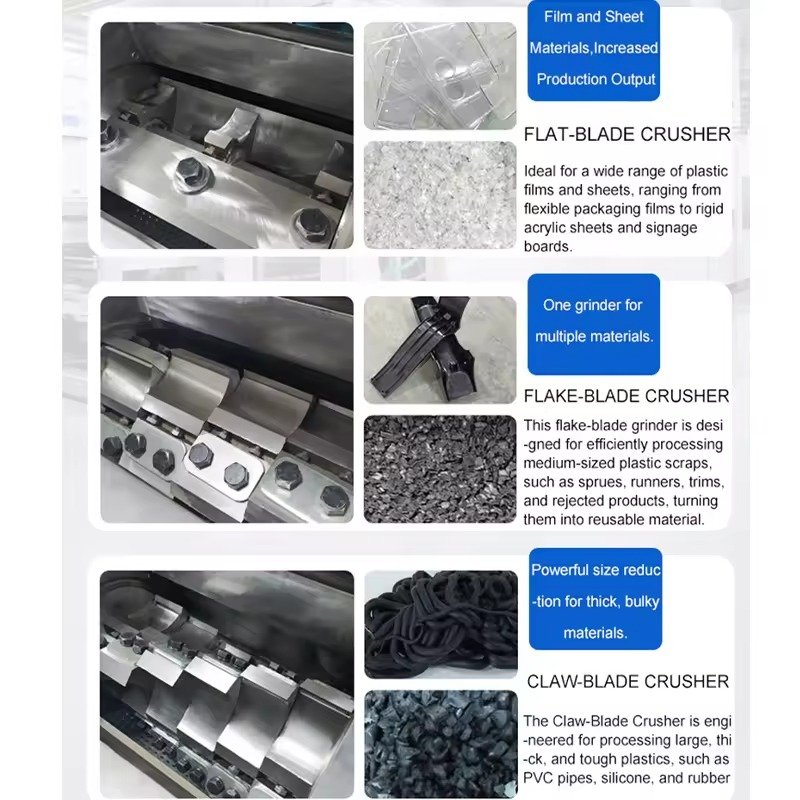

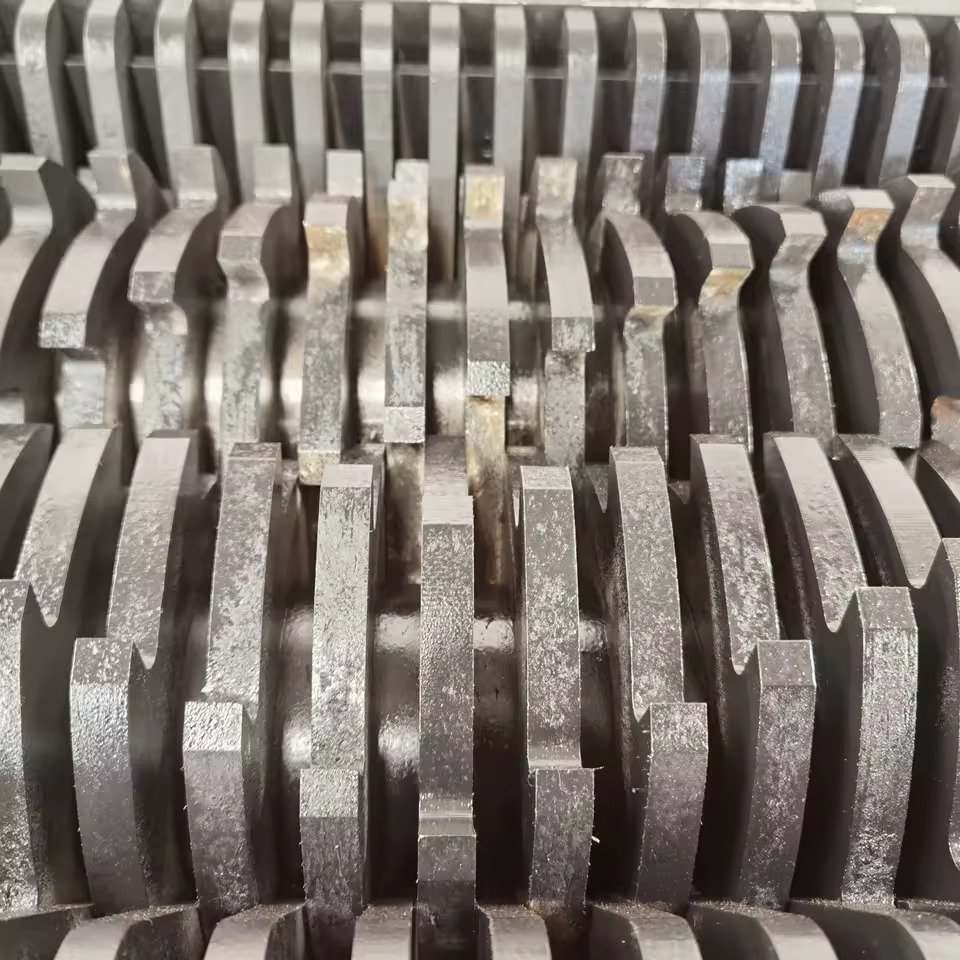

Whole pallets are fed into an industrial plastic shredder designed to handle bulky items. MAIKONG’s heavy-duty shredders feature:

- Robust cutting systems with hardened steel blades

- High-torque motors to handle tough materials

- Large feeding chambers to accommodate whole pallets

- Adjustable cutting screens for controlled output size

3. Secondary Size Reduction

After initial shredding, the material often undergoes secondary processing with a plastic crusher machine or granulator to reduce particle size further, typically to 10-12mm fragments suitable for washing and further processing.

4. Washing and Separation

The shredded material is thoroughly washed to remove contaminants such as dirt, labels, and adhesives. Separation systems remove any non-plastic components that might have been part of the pallet structure, such as metal reinforcements.

5. Drying and Further Processing

After washing, the material is dried and can be further processed into plastic pellets or flakes, ready for manufacturing new products. This closed-loop approach ensures that valuable plastic resources remain in the production cycle rather than ending up in landfills.

MAIKONG Shredding Solutions for Plastic Pallets

MAIKONG offers a comprehensive range of plastic shredder equipment specifically designed for processing plastic pallets and crates. Our machines are engineered to handle the unique challenges of these bulky, rigid items while delivering reliable performance and optimal output quality.

Industrial Shredders

Our industrial-grade shredders are designed for high-volume operations, capable of processing hundreds of pallets per hour. These robust machines feature:

- Heavy-duty cutting systems with replaceable blades

- Large feeding chambers for whole pallets

- Powerful motors ranging from 45kW to 132kW

- Hydraulic ram systems for efficient material feeding

Medium-Capacity Shredders

For medium-volume operations, our small plastic shredder models offer an excellent balance of performance and value:

- Processing capacity of 300-800 kg/hour

- Compact footprint for facilities with space constraints

- Energy-efficient operation with 22-37kW motors

- Low maintenance requirements

Compact Solutions

Our mini plastic shredder machine models are ideal for smaller operations or as part of a distributed recycling strategy:

- Processing capacity of 100-300 kg/hour

- Minimal space requirements

- Single-phase power options available

- Low initial investment cost

Customized Shredding Systems

MAIKONG also offers customized shredding systems designed specifically for your unique requirements. Our engineering team can develop complete solutions that include:

- Automated feeding systems

- Conveyor systems for material handling

- Integration with existing recycling equipment

- Custom screen sizes for specific output requirements

- Advanced control systems for optimized operation

Find Your Ideal Shredding Solution

Our experts will help you select the perfect equipment for your plastic pallet recycling needs.

Contact Us on WhatsApp

Technical Specifications for Plastic Pallet Shredders

| Model |

Motor Power |

Rotor Diameter |

Rotor Speed |

Blade Quantity |

Processing Capacity |

Output Size |

| MAIKONG-800 |

37kW |

380mm |

83RPM |

46 PCS |

400-500 kg/hr |

40-50mm |

| MAIKONG-1000 |

55kW |

380mm |

83RPM |

56 PCS |

800-1000 kg/hr |

40-50mm |

| MAIKONG-1200 |

75kW |

380mm |

83RPM |

72 PCS |

1000-1500 kg/hr |

40-50mm |

| MAIKONG-1500 |

132kW |

620mm |

83RPM |

132 PCS |

2000-3000 kg/hr |

40-50mm |

All MAIKONG shredders feature high-quality components including:

- Hardened steel blades (SKD-11, DC-53 material)

- Premium electrical components from leading manufacturers

- PLC control systems with automatic reverse for overload protection

- Heavy-duty bearings and gearboxes for continuous operation

- Customizable screen sizes to achieve desired output dimensions

For optimal performance when shredding plastic pallets, we recommend our specialized blade configurations designed specifically for rigid plastics. These blades maintain their sharpness longer when processing tough materials like HDPE and PP pallets, reducing maintenance requirements and ensuring consistent output quality.

Need Replacement Parts?

MAIKONG offers a complete range of plastic shredder parts to keep your equipment running at peak performance.

View Replacement Parts

Plastic Pallet Recycling Solutions for the Philippines

MAIKONG is committed to supporting sustainable waste management practices in the Philippines. Our plastic shredder solutions are specifically designed to address the unique challenges faced by Philippine businesses:

Local Challenges

- Limited landfill capacity in urban areas

- Increasing disposal costs

- Strict environmental regulations

- High transportation costs for unprocessed waste

- Growing public concern about plastic pollution

MAIKONG Advantages

- Machines designed for tropical conditions

- Local technical support and service

- Spare parts availability

- Training programs for operators

- Customized solutions for local requirements

Distributor and Dealer Opportunities

MAIKONG is actively seeking distribution partners in the Philippines to expand our presence and provide better local support. If you’re interested in becoming a MAIKONG distributor or dealer, we offer:

- Comprehensive product training

- Marketing support and materials

- Competitive pricing structures

- Technical certification programs

- Ongoing business development assistance

Frequently Asked Questions About Shredding Plastic Pallets

What types of plastic pallets can be processed with MAIKONG shredders?

MAIKONG shredders can process all common types of plastic pallets, including those made from HDPE, PP, PVC, and mixed plastics. Our machines are designed to handle both injection-molded and extruded pallets, as well as nestable, stackable, and rackable designs. The robust cutting system can even process pallets with metal reinforcements, though these may require specialized blade configurations.

What is the return on investment for a plastic pallet shredding system?

The ROI for a plastic pallet shredding system typically ranges from 12-24 months, depending on your volume of material, local disposal costs, and the value of recycled plastic in your market. Businesses processing large volumes of pallets often see faster returns due to significant savings on disposal fees and potential revenue from selling the processed material. MAIKONG can provide a detailed ROI analysis based on your specific circumstances.

What maintenance is required for plastic pallet shredders?

Regular maintenance for MAIKONG plastic shredders includes blade inspection and rotation/replacement, bearing lubrication, and general cleaning. Our machines are designed for easy maintenance, with accessible cutting chambers and simple blade change systems. Most customers find that a preventative maintenance schedule of checking blades every 100-200 operating hours is sufficient for processing plastic pallets. We provide comprehensive maintenance training and documentation with all our machines.

Can MAIKONG shredders process other materials besides plastic pallets?

Yes, MAIKONG shredders are versatile machines capable of processing a wide range of materials beyond plastic pallets. Depending on the model, they can handle plastic pipes, films, bottles, containers, electronic waste, wood, and many other materials. This versatility makes them an excellent investment for recycling operations that process diverse waste streams. Different materials may require specific blade configurations or operating parameters, which our technical team can advise on.

Conclusion: The Future of Plastic Pallet Recycling

Shredding plastic pallets is more than just a waste management solution—it’s a critical component of the circular economy and sustainable business practices. By investing in quality shredding equipment from MAIKONG, businesses in the Philippines can transform their waste challenges into opportunities, reducing costs while contributing to environmental protection.

As regulations continue to tighten and disposal options become more limited and expensive, proactive companies are gaining competitive advantages by implementing in-house recycling solutions. MAIKONG is proud to be at the forefront of this transition, providing reliable, efficient, and cost-effective plastic shredder machines designed specifically for the demands of plastic pallet recycling.

Contact MAIKONG today to learn how our solutions can help your business turn plastic waste into value while supporting sustainability goals. Our team is ready to provide the expertise, equipment, and support you need to succeed in your recycling initiatives.

Ready to Start Your Recycling Journey?

Take the first step toward sustainable plastic pallet management with MAIKONG.

Explore Our Shredder Range