In today’s world of increasing plastic waste, especially in the Philippines, finding efficient recycling solutions has become crucial for businesses. The small plastic shredder machine from MAIKONG offers a perfect balance of compact design and powerful performance, making it ideal for recycling facilities, manufacturing plants, and community-based sorting centers looking to manage plastic waste effectively while maximizing space and resources.

MAIKONG’s compact plastic shredder designed for efficient waste processing

What Is a Small Plastic Shredder Machine?

A small plastic shredder machine is a specialized piece of equipment designed to reduce the size of various plastic materials into smaller, more manageable pieces. Unlike their larger industrial counterparts, these compact machines are engineered specifically for operations with space constraints or lower volume requirements, making them perfect for small to medium-sized businesses in the Philippines.

MAIKONG’s small plastic shredder machine features a robust rotor system with high-quality blades that efficiently cut through different types of plastic waste. The compact design doesn’t compromise on performance, with models capable of processing between 100-1300 kg/h depending on the specific configuration.

Not Sure Which Shredder Fits Your Needs?

Our experts can help you select the perfect model based on your specific waste stream and production requirements.

Get Expert Advice

Key Advantages of MAIKONG’s Small Plastic Shredders

High-quality cutting system ensures consistent output size

Space Efficiency

Compact footprint makes it ideal for facilities with limited space while still delivering impressive throughput for its size.

Cost Effectiveness

Lower initial investment compared to large industrial shredders, with reduced power consumption and maintenance costs.

Versatility

Capable of processing various plastic types including PET bottles, PE films, PP woven bags, and rigid plastics.

Consistent Output

Produces uniform plastic granules with adjustable discharge size (typically 2-10mm) for further processing.

User-Friendly Operation

Simple controls with start/stop, reverse, and overload protection functions for safe and efficient operation.

Easy Maintenance

Modular design allows for quick blade maintenance and cleaning, minimizing downtime.

“The right small plastic shredder machine can transform your waste management process, turning plastic waste from a liability into a valuable resource.”

– MAIKONG Engineering Team

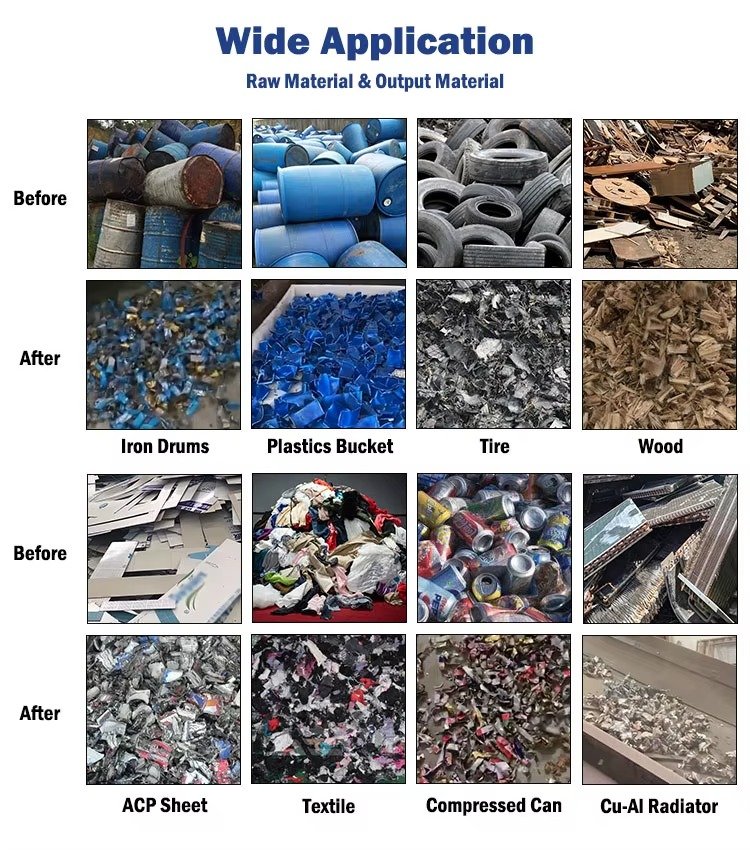

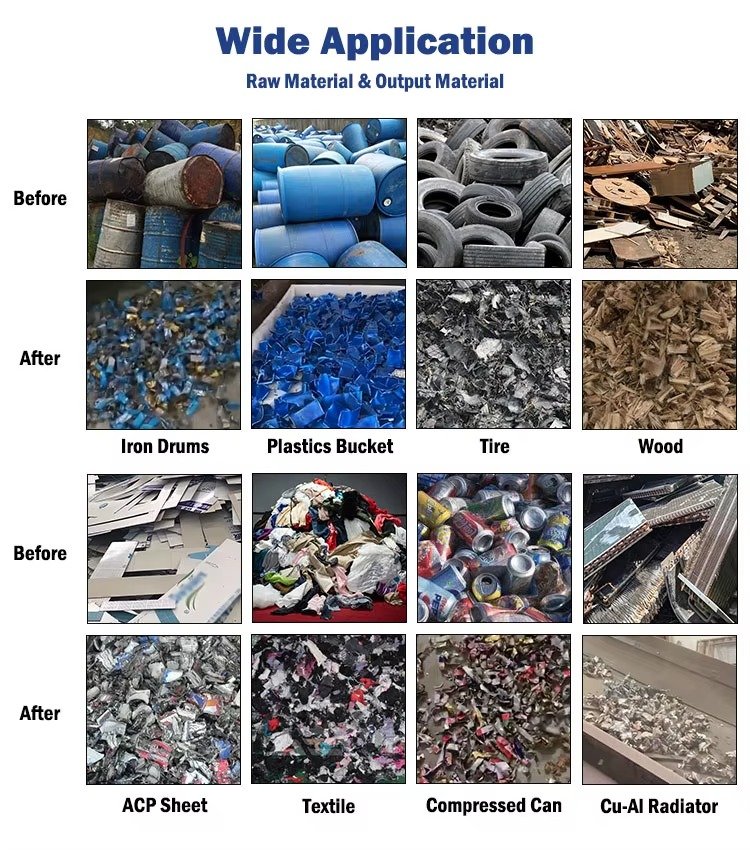

Versatile Applications Across Plastic Waste Streams

The small plastic shredder machine from MAIKONG is designed to handle a wide variety of plastic waste materials, making it an extremely versatile solution for different industries and applications.

Before and after: Various plastic waste transformed into uniform recyclable material

Ideal Materials for Processing

Soft Plastics

- PE films (stretch film, agricultural film)

- Plastic bags and packaging

- PP woven bags

- Plastic wrapping materials

Rigid Plastics

- PET bottles and containers

- Small plastic pipes and fittings

- Plastic caps and trays

- Injection molded products

Perfect For These Facilities

MAIKONG shredder integrated into a small recycling operation

- Small to medium plastic recycling plants

- Film and packaging waste processing stations

- Injection and extrusion waste recovery lines

- Community recycling centers

- Small manufacturing workshops

- R&D or educational laboratories

Ready to Start Recycling Your Plastic Waste?

Contact our team today to discuss how our small plastic shredder machine can be integrated into your facility.

WhatsApp Consultation

Technical Specifications and Models

MAIKONG offers several models of small plastic shredder machines to accommodate different capacity requirements and material types. Our engineering team has optimized each model for specific applications while maintaining the core benefits of compact design and reliable performance.

Detailed view of key components in MAIKONG’s shredder design

| Model |

Rotary Blades (pcs) |

Fixed Blades (pcs) |

Spindle Diameter (mm) |

Motor Power (kW) |

Capacity (kg/h) |

| MK-600 |

36 |

1 |

220 |

30 |

300-500 |

| MK-800 |

56 |

2 |

320 |

37 |

500-800 |

| MK-1000 |

68 |

2 |

350 |

55 |

600-1000 |

Key Components and Features

Drive System

- High-quality motors (Siemens/ABB options available)

- Robust gearbox for optimal torque transfer

- Energy-efficient design for lower operating costs

Cutting System

- Special alloy blades for extended service life

- Adjustable screen for controlled output size

- Easy access for maintenance and blade changes

Control System

- Standard electrical control cabinet

- Start/stop, reverse, and overload protection

- Optional PLC control for advanced operations

Safety Features

- Emergency stop buttons

- Overload protection system

- Safety interlocks on access panels

Output Quality: MAIKONG’s small plastic shredder machines produce uniform plastic granules with a discharge size of approximately 2-10 mm, controlled by adjustable screens for consistent quality.

Customization Options for Your Specific Needs

At MAIKONG, we understand that each recycling operation has unique requirements. That’s why we offer various customization options for our small plastic shredder machines to ensure you get the perfect solution for your specific application.

Customized shredder configuration with specialized infeed system

Available Add-ons and Modifications

Infeed Systems

- Automatic belt conveyor

- Screw conveyor

- Inclined chute for forklift loading

Output Collection

- Cyclone collection with blower

- Belt conveyor system

- Screw conveyor for direct feed

Rotor Options

- Standard multi-purpose rotor

- Specialized film/flexible material rotor

- Heavy-duty rotor for challenging materials

Structural Modifications

- Elevated rack for integration

- Enlarged shredding chamber

- Custom hopper design

Power Options

- Increased motor power

- Hydraulic motor option

- Custom voltage configurations

Feeding Assistance

- Vertical ram pusher

- Specialized lid design

- Material pre-conditioning

Custom Solutions: Our engineering team can develop specialized solutions for unique materials or processing requirements. Contact us to discuss your specific needs.

Complete system with customized material handling components

Processing Different Types of Plastic Waste

The versatility of MAIKONG’s small plastic shredder machine extends to handling various types of plastic waste, making it an ideal solution for recycling operations dealing with mixed plastic streams.

Various plastic types before and after shredding process

Commonly Processed Plastic Types

#2 HDPE

- Plastic totes and trays

- Crates, bins, and bottles

- Storage containers and buckets

- Caps, lids, and jugs

- Pallets and pipe sections

#4 LDPE/LLDPE

- Plastic films and sheets

- Stretch and shrink wrap

- Bags and flexible packaging

- Rotomolded parts

- Agricultural films

#5 PP

- Woven bags and sacks

- Containers and bins

- Bottle caps and closures

- Automotive parts

- Packaging materials

Processing Challenges and Solutions

Flexible Materials

Films and flexible plastics can wrap around standard rotors. Our specialized film rotor design prevents wrapping and ensures efficient cutting of even the thinnest materials.

Rigid Materials

Hard plastics require more cutting force. Our heavy-duty blade configurations and robust drive systems handle rigid materials without excessive wear or power consumption.

Contaminated Materials

Our shredders can handle moderate contamination. For heavily contaminated streams, we recommend pre-cleaning or our specialized contamination-resistant blade design.

Mixed Plastic Types

When processing mixed plastics, our universal blade configuration provides the versatility needed to handle varying material properties in a single pass.

Need Help With Your Specific Plastic Waste?

Our technical team can analyze your material stream and recommend the optimal shredder configuration.

Email Our Technical Team

Integration with Existing Recycling Systems

MAIKONG’s small plastic shredder machines are designed for seamless integration into both new and existing recycling operations, serving as a critical first step in the plastic recycling process.

Complete recycling line with shredder as the primary processing stage

Common Integration Scenarios

Standalone Processing

Used independently for size reduction before manual sorting or external processing, ideal for smaller operations or specific waste streams.

Pre-Processing Stage

Integrated as the first step in a complete recycling line, feeding into washing, separation, and granulation systems.

In-House Waste Management

Installed within manufacturing facilities to process production scrap and rejected parts for immediate reuse.

Post-Shredding Options

Material flow options after the shredding process

- Direct Reuse: Shredded material can sometimes be directly reintroduced into production processes, especially for clean in-house scrap.

- Further Size Reduction: For applications requiring smaller particle size, the output can be fed into a granulator for further processing.

- Washing and Separation: Contaminated materials can proceed to washing and separation systems to remove impurities.

- Pelletizing: Clean shredded material can be extruded and pelletized to create recycled plastic pellets for manufacturing.

- Alternative Applications: Shredded plastic can also be used for RDF (Refuse Derived Fuel) or as feedstock for pyrolysis systems.

“The versatility of our small plastic shredder machine makes it the perfect starting point for any plastic recycling operation, regardless of scale or complexity.”

– MAIKONG Technical Department

Why Choose MAIKONG for Your Plastic Shredding Needs

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

With over 20 years of experience in plastic recycling equipment, MAIKONG has established itself as a trusted provider of high-quality shredding solutions. Our small plastic shredder machines combine innovative design, robust construction, and user-friendly operation to deliver exceptional value for recycling operations of all sizes.

Why Customers Choose MAIKONG

- Internationally recognized quality components and construction

- Comprehensive technical support and after-sales service

- Customized solutions tailored to specific requirements

- Energy-efficient designs that reduce operating costs

- Proven reliability with machines operating worldwide

From initial consultation to installation and ongoing support, MAIKONG is committed to ensuring your plastic recycling operation succeeds. Our team of experts works closely with each customer to understand their specific needs and provide the optimal solution for their application.

Ready to Transform Your Plastic Waste into Value?

Contact MAIKONG today to discuss your requirements and receive a customized quote for the perfect small plastic shredder machine for your operation.

Explore our complete range of plastic recycling equipment, including mini plastic shredder machines, small plastic shredders, industrial plastic shredders, and plastic shredder parts. Visit our about us page to learn more about MAIKONG’s commitment to quality and innovation in plastic recycling technology.