Why Choose MAIKONG’s Mini Plastic Shredder Kit

Based in SZ, GD, MAIKONG has established itself as a premier manufacturer of plastic recycling equipment. With years of industry experience and a commitment to innovation, we specialize in designing and producing high-quality mini plastic shredder machine solutions that meet the diverse needs of businesses throughout the Philippines and beyond.

Premium Quality Components

- High-grade Chinese supply chain ensuring top-quality parts

- Advanced production equipment for precision manufacturing

- AR500 steel blades for superior durability and cutting performance

- Energy-efficient motors designed for continuous operation

- Comprehensive customization capabilities for specific requirements

Exceptional Customer Support

- Dedicated technical support via WhatsApp for immediate assistance

- Detailed assembly instructions and maintenance guides

- Reliable after-sales service and maintenance support

- Local expertise for Philippine market requirements

- Competitive pricing with excellent value proposition

Ready to Optimize Your Plastic Recycling Process?

Our team is standing by to help you find the perfect mini plastic shredder kit for your specific needs.

Request a Quote Today

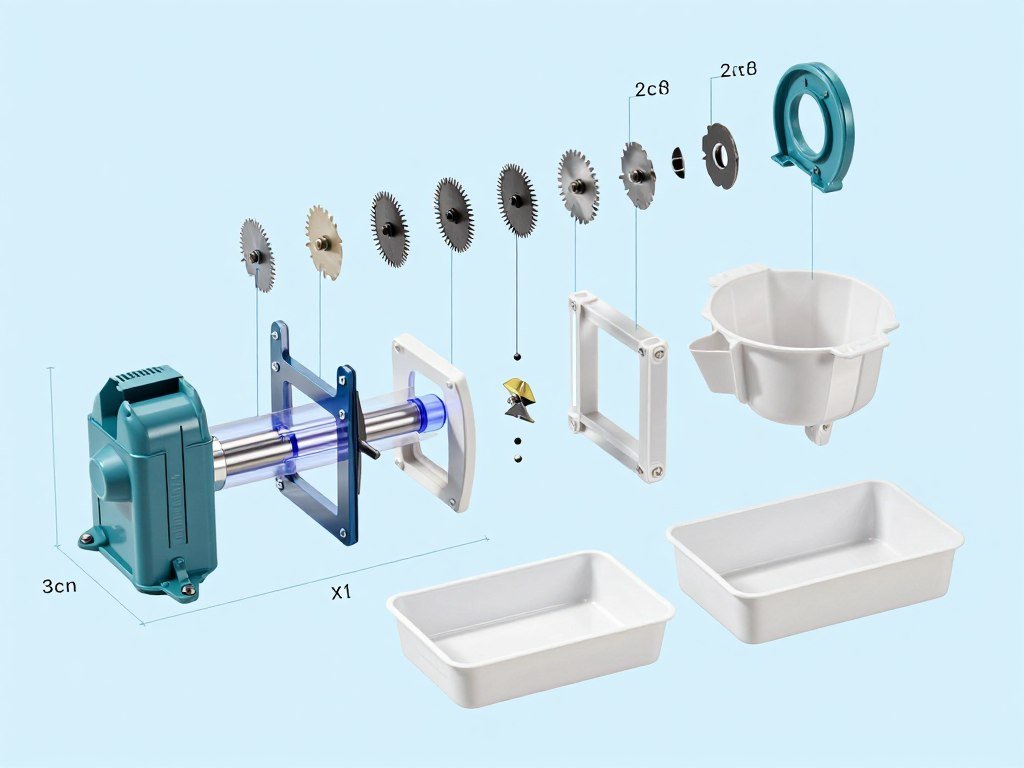

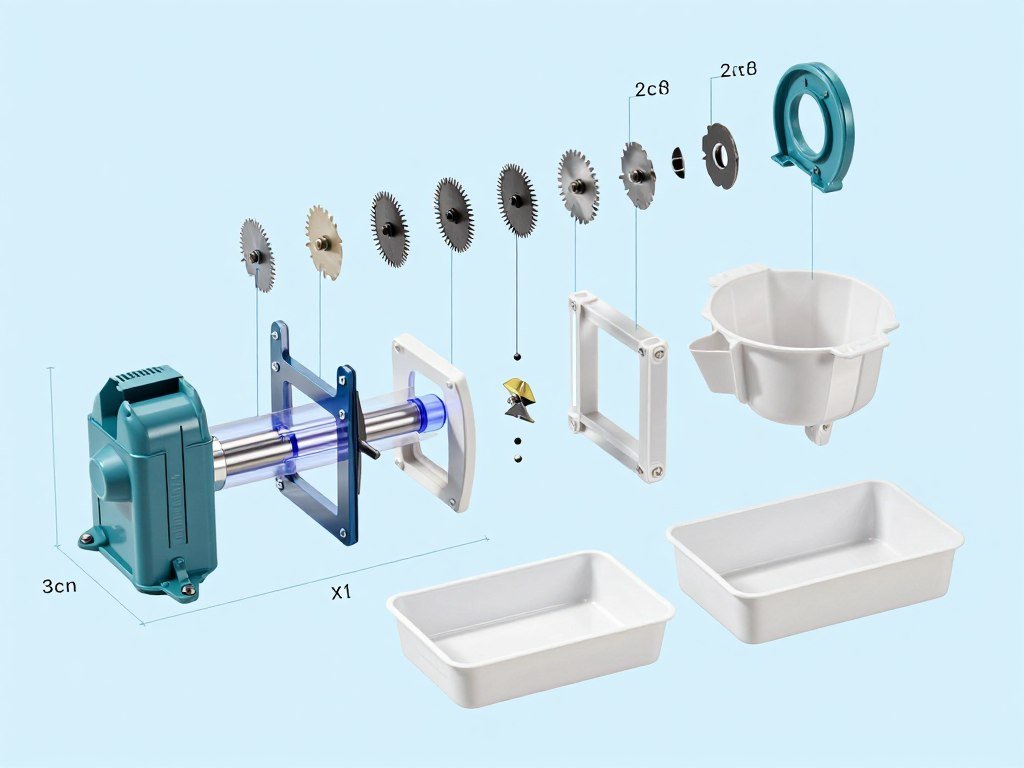

What’s Included in Our Mini Plastic Shredder Kit

The MAIKONG mini plastic shredder kit comes with everything you need to set up an efficient plastic recycling operation. Each component is carefully designed and manufactured to ensure optimal performance and durability.

Exploded view of the mini plastic shredder kit showing all major components

| Component |

Quantity |

Material |

Function |

| Frame Panels |

6 |

Powder-coated Steel |

Structural support and housing |

| Cutting Blades |

12-18 |

AR500 Steel |

Material shredding |

| Drive Shaft |

1-2 |

Hardened Steel |

Power transmission |

| Spacers |

24-36 |

Steel |

Blade spacing and alignment |

| Motor Mount |

1 |

Steel |

Secure motor attachment |

| Safety Hopper |

1 |

Steel/Plastic |

Safe material feeding |

| Collection Tray |

1 |

Steel/Plastic |

Shredded material collection |

| Assembly Hardware |

Set |

Steel |

Component assembly |

| Instruction Manual |

1 |

Digital/Print |

Assembly and operation guidance |

Each mini plastic shredder kit can be customized based on your specific requirements. Contact our technical team to discuss motor options, blade configurations, and additional accessories.

Technical Specifications and Performance

The MAIKONG mini plastic shredder kit is designed for optimal performance while maintaining a compact footprint. Our engineering team has carefully balanced power, efficiency, and durability to create a solution that meets the needs of Philippine businesses.

MAIKONG mini plastic shredder kit in operation processing plastic bottles

Key Performance Metrics

Processing Capacity

4.5/5

Standard Model Specifications

| Specification |

MK-MS100 |

MK-MS200 |

MK-MS300 |

| Motor Power |

3 kW |

5.5 kW |

7.5 kW |

| Rotor Diameter |

180 mm |

220 mm |

260 mm |

| Blade Count |

12 |

18 |

24 |

| Hopper Size |

300×250 mm |

400×350 mm |

500×400 mm |

| Output Capacity |

50-80 kg/h |

100-150 kg/h |

150-200 kg/h |

| Dimensions (L×W×H) |

850×600×1100 mm |

950×700×1250 mm |

1050×800×1350 mm |

| Output Size |

10-20 mm |

10-30 mm |

10-30 mm |

Customization Available: All MAIKONG mini plastic shredder kits can be customized to meet specific requirements. Contact our technical team to discuss your unique needs.

Need Technical Assistance?

Our engineering team is available to help you select the right specifications for your application.

Contact via WhatsApp

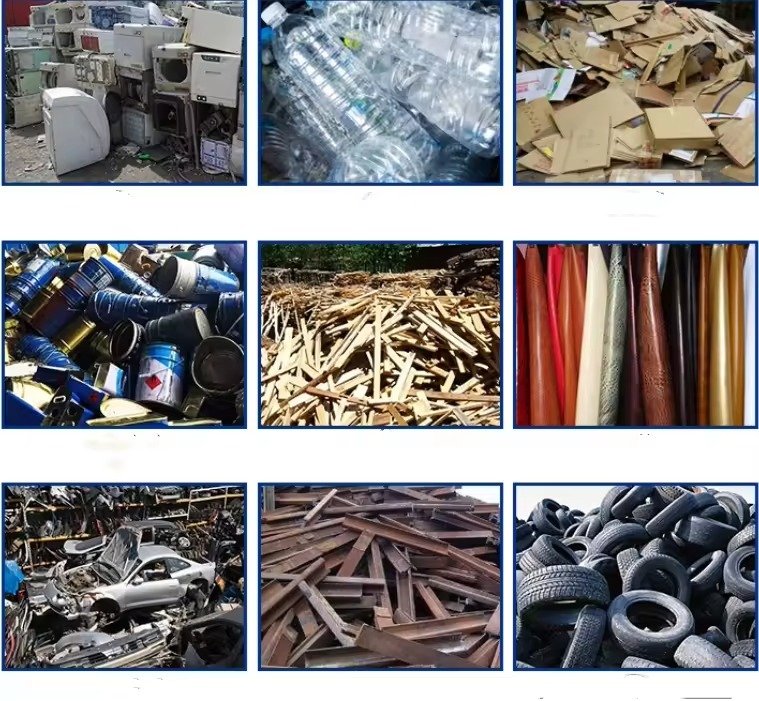

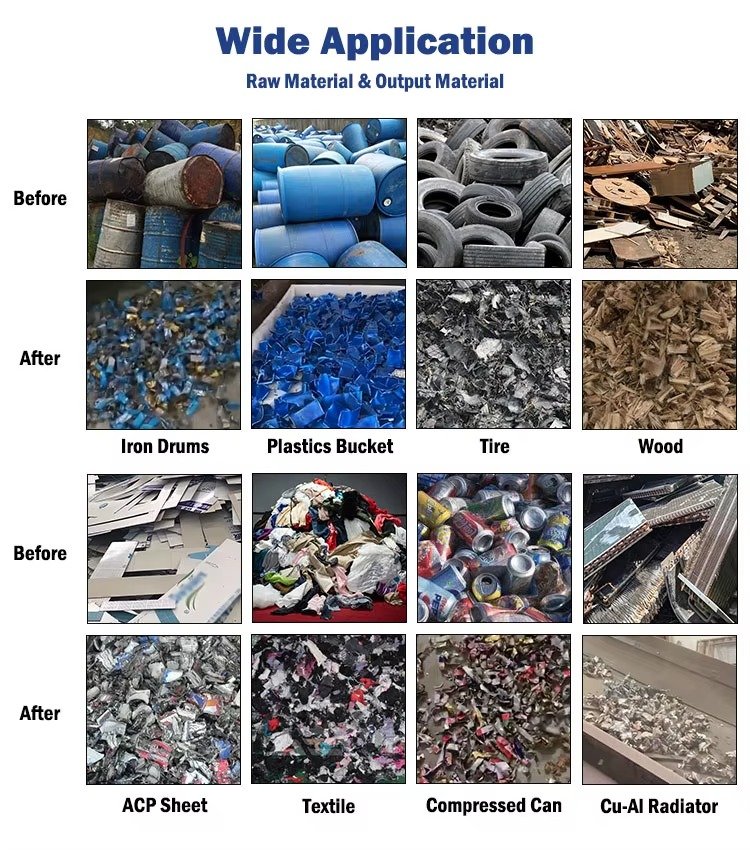

Applications of Mini Plastic Shredder Kits in the Philippines

The versatile nature of our mini plastic shredder kits makes them ideal for various applications across different industries in the Philippines. From small manufacturing operations to community recycling initiatives, these compact machines provide effective solutions for plastic waste management.

MAIKONG mini plastic shredder kit in use at a Philippine manufacturing facility

Manufacturing Facilities

Perfect for processing production scrap from injection molding, thermoforming, extrusion, and blow molding operations. Reclaim valuable materials and reduce waste disposal costs.

Recycling Centers

Ideal for small to medium recycling facilities processing community plastic waste. Compact size makes it perfect for operations with space constraints while maintaining excellent throughput.

Educational Institutions

Suitable for technical schools and universities teaching recycling technologies and sustainable waste management practices. Safe operation with comprehensive safety features.

Types of Plastic Processed

Common Materials

- #1 PET – Bottles, containers, packaging

- #2 HDPE – Bottles, jugs, crates, bins, caps

- #4 LDPE – Films, bags, flexible packaging

- #5 PP – Containers, caps, trays, automotive parts

- #6 PS – Packaging, disposable items

Industrial Scrap

- Injection molding waste – Runners, sprues, rejects

- Thermoforming trim – Edge scrap, rejected parts

- Extrusion purge – Start-up waste, color changes

- Blow molding flash – Excess material, rejects

- Production scrap – Quality rejects, test pieces

Common plastic types processed by MAIKONG mini plastic shredder kits

“The growing plastic waste challenge in the Philippines requires practical, affordable solutions. Our mini plastic shredder kits are designed specifically to help local businesses implement effective recycling programs without major infrastructure investments.”

– MAIKONG Engineering Team

Operation and Maintenance

Understanding how to properly operate and maintain your mini plastic shredder kit is essential for maximizing performance and longevity. MAIKONG provides comprehensive support to ensure you get the most from your investment.

Regular maintenance ensures optimal performance of your mini plastic shredder kit

How Our Mini Plastic Shredder Works

- Material Feeding: Plastic waste is loaded into the hopper at the top of the machine.

- Shredding Process: The material enters the cutting chamber where rotating blades mounted on a shaft cut against stationary blades.

- Size Control: A screen at the bottom of the cutting chamber ensures consistent output size.

- Discharge: The shredded material exits through the discharge chute, ready for further processing or collection.

Maintenance Schedule

| Maintenance Task |

Frequency |

Tools Required |

Importance |

| Blade Inspection |

Weekly |

Allen keys, wrenches |

Critical |

| Blade Rotation/Replacement |

Every 100-200 hours |

Allen keys, wrenches, mallet |

Critical |

| Bearing Lubrication |

Monthly |

Grease gun, lubricant |

High |

| Drive System Check |

Monthly |

Visual inspection tools |

High |

| Cutting Chamber Cleaning |

Weekly |

Brush, compressed air |

Medium |

| Screen Cleaning/Replacement |

As needed |

Wrenches, cleaning tools |

Medium |

Safety First: Always disconnect power before performing any maintenance on your mini plastic shredder kit. Wear appropriate safety gear including gloves and eye protection when handling blades.

Proper blade maintenance diagram for MAIKONG mini plastic shredder kits

Technical Support

When you purchase a mini plastic shredder kit from MAIKONG, you gain access to our comprehensive support system:

Online Technical Support

Our technical team is available via WhatsApp for immediate assistance with any operational questions or troubleshooting needs. Simply add our technical support: 008613-51090-74-01

Maintenance Guidance

Detailed maintenance schedules and procedures to ensure optimal performance and longevity of your equipment.

Spare Parts Supply

Quick access to genuine MAIKONG replacement parts to minimize downtime and maintain performance. Visit our plastic shredder parts page for more information.

Training

Comprehensive operator training available to ensure safe and efficient machine operation.