In the world of plastic recycling, choosing between granulators and shredders can significantly impact your operation’s efficiency and profitability. Both machines serve the essential purpose of size reduction, but they differ in design, application, and output. This comprehensive guide will help you understand the key differences between these two machines and make an informed decision for your plastic recycling needs in the Philippines.

Basics: Shredders vs. Granulators

Before diving into the specifics, it’s important to understand what each machine does and how they differ fundamentally. This knowledge forms the foundation for making the right choice for your specific application.

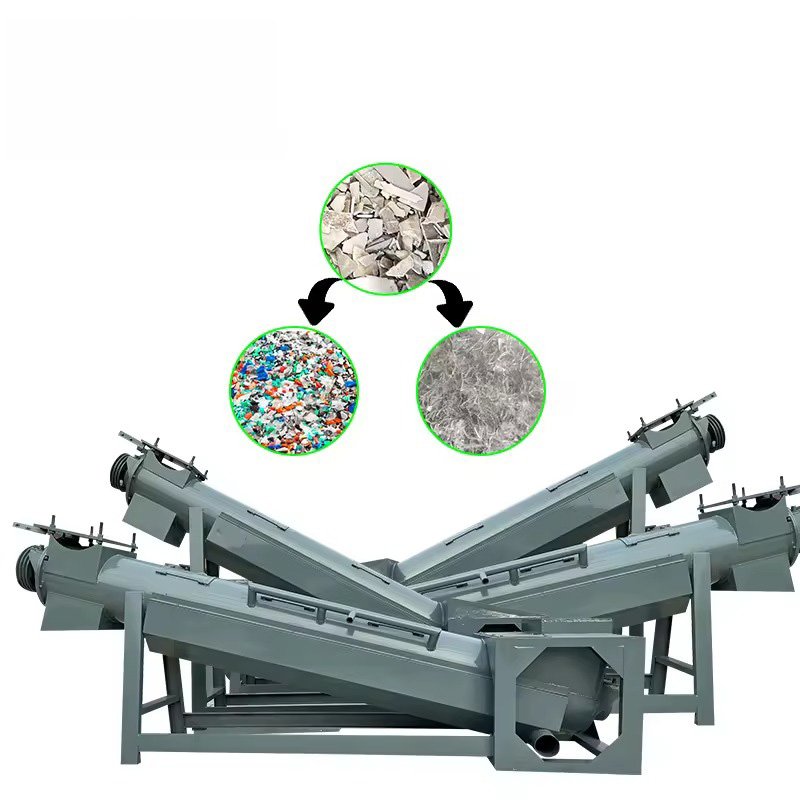

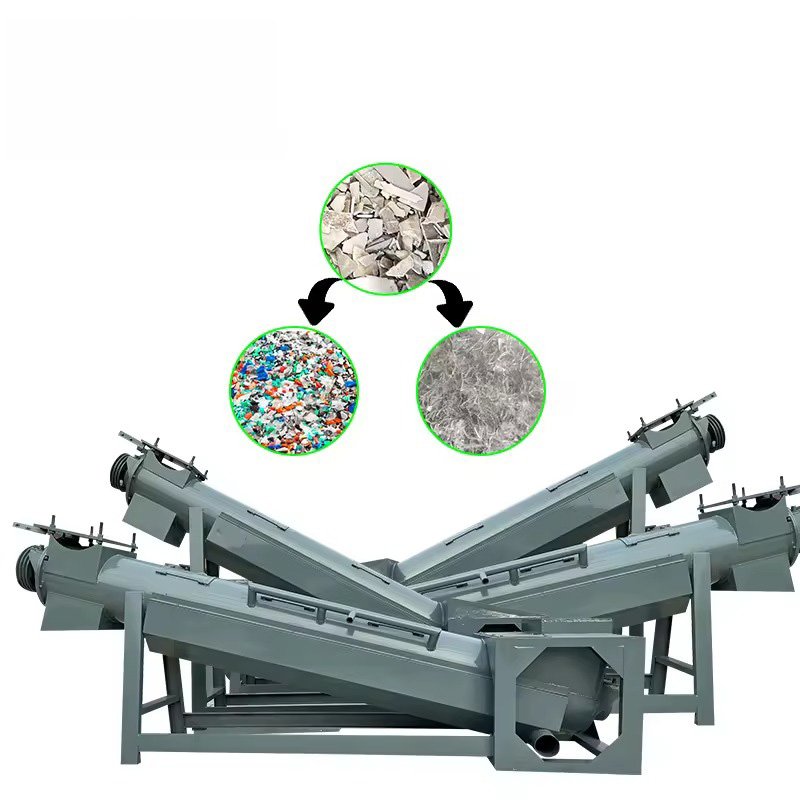

Industrial shredders and granulators differ in design and application

What Are Plastic Shredders?

A plastic shredder is a robust machine designed to reduce large plastic materials into smaller, more manageable pieces. Shredders typically feature dual-shaft or four-shaft cutting systems with low-speed, high-torque motors that provide tremendous cutting force.

The primary function of shredders is to process bulky materials that would otherwise overwhelm other size reduction equipment. They’re often the first step in a comprehensive recycling system, preparing materials for further processing.

What Are Granulators?

Granulators, on the other hand, are designed to produce uniform, small-sized particles. They typically feature a rotor with multiple blades that rotate at high speeds against stationary bed knives. This high-speed cutting action creates a clean, consistent cut.

Granulators are often used as a secondary processing step after shredding or as a standalone solution for smaller, cleaner plastic waste streams. They produce granules that can be directly used in injection molding or extrusion processes.

Key Features of Shredders:

- Low-speed, high-torque operation

- Robust construction for handling tough materials

- Larger cutting chamber for bulky items

- Higher power consumption

- Produces irregular-sized output

- Ideal for primary size reduction

Key Features of Granulators:

- High-speed cutting action

- Precision cutting for uniform output

- Smaller cutting chamber

- Lower power consumption

- Produces consistent granules

- Ideal for secondary processing or clean waste

Applications and Material Considerations

The type of plastic waste you’re processing plays a crucial role in determining whether a shredder or granulator is more suitable for your operation.

Different types of plastic waste require specific processing equipment

When to Choose a Plastic Shredder

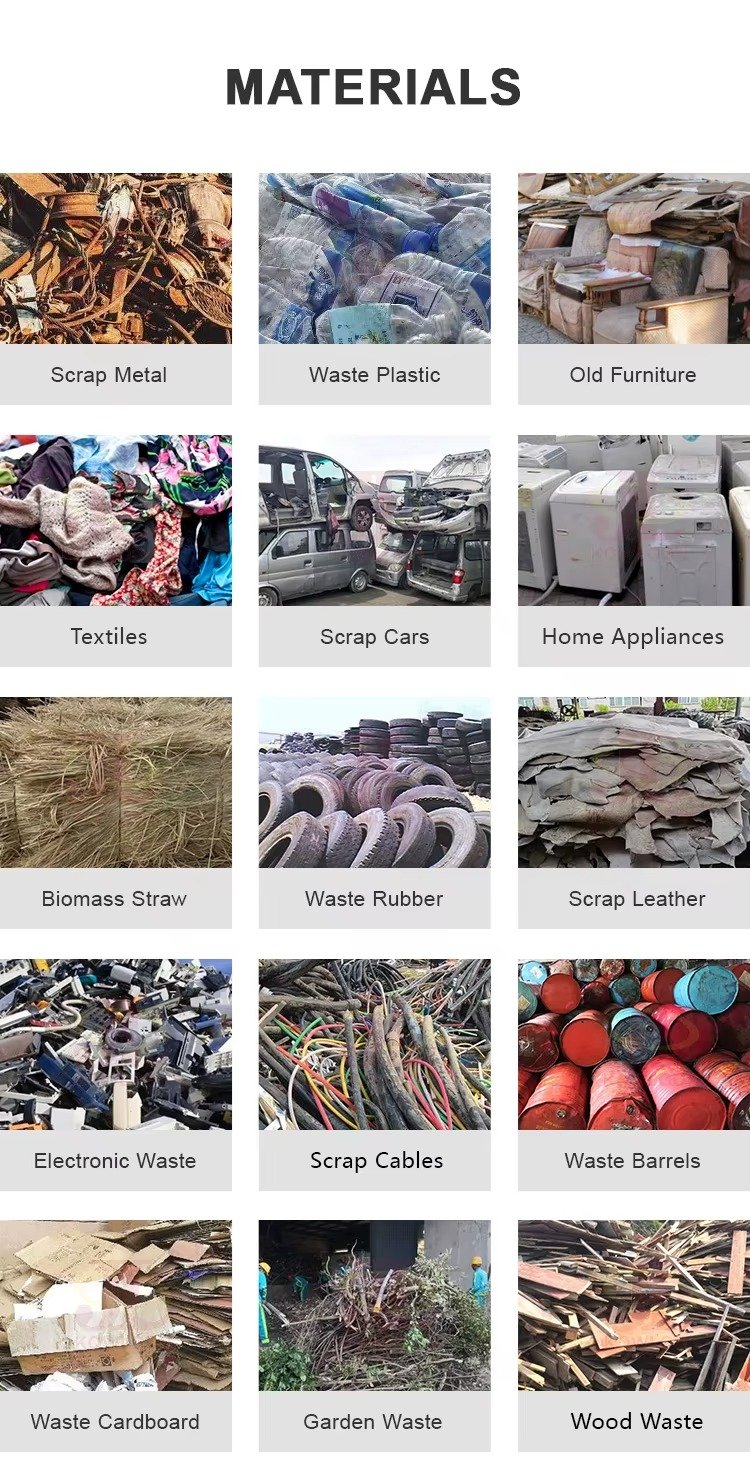

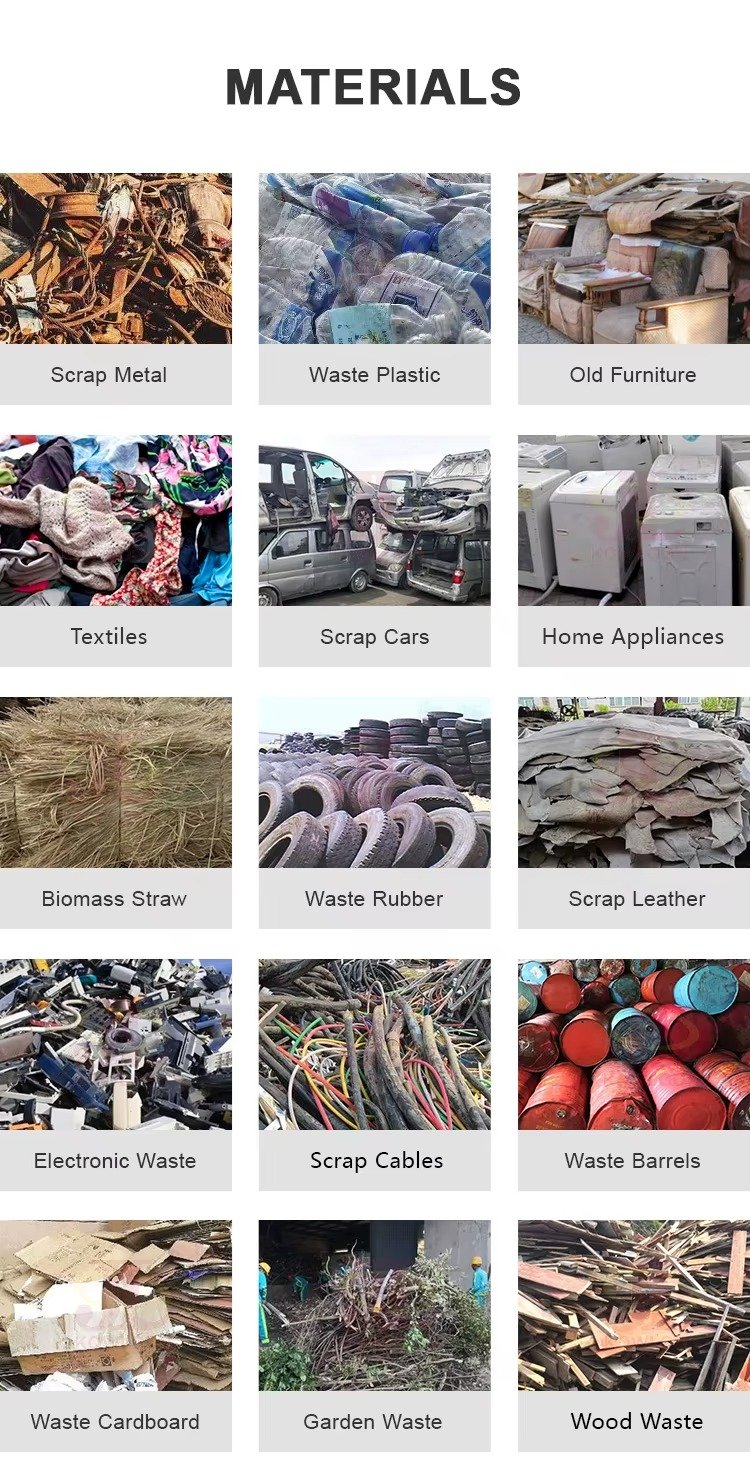

Shredders excel at processing challenging materials that would damage or jam other equipment. MAIKONG’s industrial shredders are specifically designed to handle a wide range of difficult materials.

Ideal Materials for Shredders:

- Bulky plastic items (crates, pallets, buckets)

- Thick-walled plastic products

- Contaminated plastic waste

- Mixed plastic waste streams

- Plastic lumps and purges

- Post-consumer plastic waste

- Large plastic pipes and profiles

When to Choose a Granulator

Granulators are the preferred choice when your goal is to produce uniform, small-sized particles ready for reprocessing. They work best with cleaner, pre-sorted plastic waste.

Ideal Materials for Granulators:

- Clean production scrap

- Runners and sprues from injection molding

- Thin-walled plastic products

- Pre-shredded plastic materials

- Homogeneous plastic waste streams

- Plastic films and sheets

- Small plastic parts and components

Combined Systems: When You Need Both

In many industrial recycling operations, the most efficient solution is a combined system that incorporates both shredders and granulators. This approach maximizes processing efficiency and output quality.

Integrated systems combine shredders and granulators for optimal processing

“For comprehensive plastic recycling operations, a two-stage approach with primary shredding followed by granulation often yields the best results in terms of throughput, energy efficiency, and final product quality.”

– MAIKONG Engineering Team

Technical Comparison: Shredders vs. Granulators

Understanding the technical differences between these machines will help you make a more informed decision based on your specific requirements.

| Feature |

Plastic Shredders |

Granulators |

| Operating Speed |

Low (10-100 RPM) |

High (300-900 RPM) |

| Torque |

High |

Moderate |

| Output Size |

Variable (10-100mm) |

Uniform (3-12mm) |

| Noise Level |

Lower |

Higher |

| Power Consumption |

Higher |

Lower |

| Maintenance |

Less frequent |

More frequent |

| Contamination Tolerance |

High |

Low |

| Initial Investment |

Higher |

Lower |

The cutting mechanism of a MAIKONG plastic shredder

Energy Efficiency Considerations

When evaluating shredders and granulators, energy consumption is an important factor to consider, especially for operations in the Philippines where energy costs can significantly impact overall profitability.

Shredders Energy Profile:

- Higher initial power draw

- More efficient for processing large volumes

- Lower energy per kg for bulky materials

- Variable speed options for optimization

Granulators Energy Profile:

- Lower initial power requirements

- Continuous high-speed operation

- More efficient for smaller, cleaner materials

- Higher energy per kg for bulky materials

Energy-Saving Tip: MAIKONG’s latest generation of plastic shredders incorporates advanced energy management systems that can reduce power consumption by up to 30% compared to conventional models, making them an excellent choice for operations in the Philippines concerned about energy costs.

Size and Space Considerations

The physical dimensions and space requirements of shredders and granulators can vary significantly, which is an important consideration for facilities with limited space.

Size comparison: Industrial vs. mini plastic shredder machines

Industrial Shredders

Industrial shredders are typically larger machines designed for high-volume processing. They require substantial floor space and often need to be installed in dedicated areas with appropriate infrastructure.

Key Specifications of MAIKONG Industrial Shredders:

- Dimensions: 3700-6500mm (L) × 1800-2500mm (W) × 2200-2800mm (H)

- Weight: 3000-15000kg

- Motor Power: 37kW-132kW

- Processing Capacity: 500-5000kg/hr

- Installation Requirements: Reinforced concrete floor, 3-phase power supply

Mini and Small Shredders

For operations with space constraints or lower volume requirements, MAIKONG offers mini and small shredders that provide efficient size reduction in a more compact footprint.

Key Specifications of MAIKONG Mini Shredders:

- Dimensions: 1100-2500mm (L) × 800-1100mm (W) × 1400-1600mm (H)

- Weight: 500-2000kg

- Motor Power: 5.5kW-15kW

- Processing Capacity: 50-300kg/hr

- Installation Requirements: Standard industrial flooring, single or 3-phase power

Small shredders are ideal for operations with space limitations

Space-Saving Solution: For Philippine businesses with limited floor space, MAIKONG’s small plastic shredders offer an excellent balance of processing capability and compact design. These units can be installed in existing production areas without requiring extensive facility modifications.

Maintenance and Operational Considerations

The long-term success of your plastic recycling operation depends not just on choosing the right equipment but also on proper maintenance and operation. Understanding the maintenance requirements of shredders and granulators will help you plan for total cost of ownership.

Regular maintenance ensures optimal performance of plastic shredders

Maintenance Requirements for Shredders

MAIKONG plastic shredders are designed for durability and ease of maintenance, with several features that reduce downtime and maintenance costs.

Key Maintenance Aspects:

- Blade Sharpening/Replacement: Typically every 200-500 operating hours depending on materials

- Bearing Lubrication: Monthly or per manufacturer’s recommendation

- Drive System Inspection: Quarterly

- Hydraulic System (if applicable): Oil change every 2000 hours

- Electrical Components Check: Monthly

Operational Best Practices

Maximizing the efficiency and lifespan of your size reduction equipment requires following operational best practices specific to the Philippine operating environment.

For Shredders:

- Proper material sorting to remove metals and non-processable items

- Gradual feeding to prevent overloading

- Regular cleaning of the cutting chamber

- Monitoring motor temperature in hot environments

- Adjusting cutting gaps based on material type

For Granulators:

- Pre-cutting large items before processing

- Maintaining sharp blades for clean cuts

- Regular screen inspection and cleaning

- Proper ventilation to prevent overheating

- Consistent material feeding for uniform output

MAIKONG offers a complete range of shredder parts and accessories

Important: In the humid Philippine climate, additional moisture protection measures may be necessary for electrical components. MAIKONG machines are designed with tropical conditions in mind, featuring enhanced moisture resistance and corrosion protection.

Cost Analysis: Investment vs. Return

Understanding the financial aspects of investing in plastic recycling equipment is crucial for making a sound business decision. Here’s a comparative analysis of shredders versus granulators from a cost perspective.

Cost comparison across different machine categories

Initial Investment:

- Industrial Shredders: Higher initial cost (₱500,000-₱5,000,000+)

- Mini Shredders: Moderate investment (₱200,000-₱500,000)

- Small Shredders: Lower entry point (₱100,000-₱300,000)

- Granulators: Variable depending on size (₱150,000-₱1,000,000)

Operational Costs:

- Energy Consumption: Shredders typically higher per hour, but may be lower per kg processed

- Maintenance: Shredders generally require less frequent but more expensive maintenance

- Labor: Similar requirements for both types of machines

- Consumables: Blade replacement costs are typically higher for granulators due to more frequent changes

Return on Investment Factors:

- Material Value: Higher-quality output from granulators may command better prices

- Processing Volume: Shredders excel at handling larger volumes efficiently

- Operational Efficiency: Combined systems often provide the best overall ROI

- Waste Reduction: On-site recycling significantly reduces waste disposal costs

- Energy Costs: Important consideration in the Philippines where electricity rates can be high

“The right size reduction equipment is not just a cost but an investment that pays dividends through increased material recovery, reduced waste disposal costs, and potential new revenue streams from recycled materials.”

Request a Customized ROI Analysis

Our team can provide a detailed return on investment analysis based on your specific operation, material types, and processing volumes.

Get Your Free ROI Analysis

How to Choose the Right Machine for Your Needs

Selecting between a shredder and a granulator—or determining if you need both—requires careful consideration of several factors specific to your operation.

Decision flowchart for selecting the appropriate size reduction equipment

Key Decision Factors

Material Characteristics:

- Bulky, thick materials: Shredders are typically better suited

- Thin, clean materials: Granulators may be more efficient

- Contaminated materials: Shredders handle contamination better

- Mixed waste streams: Shredders offer more versatility

Volume Requirements:

- High volume (500+ kg/hr): Industrial shredders or combined systems

- Medium volume (100-500 kg/hr): Small to medium shredders or larger granulators

- Low volume ( Mini shredders or small granulators

- Intermittent processing: Consider equipment with start/stop capabilities

Output Requirements:

- Coarse reduction (pre-processing): Shredders are ideal

- Fine, uniform particles: Granulators excel at this

- Direct reuse in production: Granulators typically provide suitable output

- Further processing required: Shredders as first step in multi-stage system

Output comparison: Shredder particles (left) vs. granulator particles (right)

MAIKONG’s Recommendation Process

At MAIKONG, we understand that choosing the right equipment is a significant decision. Our expert team follows a structured approach to help you select the optimal solution:

- Material Analysis: We evaluate your specific plastic waste stream composition, volume, and characteristics

- Process Integration: We consider how the new equipment will integrate with your existing processes

- Space Assessment: We account for your available floor space and facility constraints

- Growth Planning: We factor in your future expansion plans and potential volume increases

- Budget Alignment: We work within your investment parameters to maximize value

Get Expert Guidance

Not sure which machine is right for your operation? Our specialists can provide personalized recommendations based on your specific requirements.

Email Our Experts

Conclusion: Making the Right Choice for Your Plastic Recycling Needs

Choosing between granulators and shredders requires careful consideration of your specific materials, processing requirements, and operational constraints. In many cases, the ideal solution may involve both types of equipment working in sequence to achieve optimal results.

MAIKONG offers a comprehensive range of plastic size reduction equipment designed specifically for the needs of businesses in the Philippines. From industrial shredders for high-volume operations to mini plastic shredders for smaller facilities, our machines are built to deliver reliable performance in demanding environments.

MAIKONG plastic shredder installation at a Philippine recycling facility

By investing in the right size reduction equipment, you’re not just purchasing a machine—you’re implementing a solution that can transform waste into value, reduce disposal costs, and contribute to a more sustainable future for the Philippines.

Ready to Transform Your Plastic Recycling Operation?

Contact MAIKONG today to discuss your specific needs and discover how our plastic shredders and granulators can help you achieve your recycling goals.

“The right equipment is the foundation of efficient plastic recycling. At MAIKONG, we’re committed to helping Philippine businesses find the perfect solution for their unique needs.”

– MAIKONG Engineering Team, GD, SZ