Plastic waste management presents a significant challenge for manufacturing and recycling operations across the Philippines. An industrial plastic waste shredder serves as the cornerstone of effective plastic recycling systems, transforming bulky waste into valuable recyclable material. This comprehensive guide explores how MAIKONG’s advanced shredding technology can revolutionize your plastic waste processing operations while delivering substantial cost savings and environmental benefits.

What is an Industrial Plastic Waste Shredder?

An industrial plastic waste shredder is a robust machine designed to reduce large plastic items into smaller, manageable pieces. These powerful machines use specialized cutting mechanisms to process various types of plastic waste, from production scraps to post-consumer materials. Unlike smaller shredders, industrial models can handle high volumes continuously, making them essential for manufacturing facilities, recycling plants, and waste management operations.

How MAIKONG Plastic Shredders Work

MAIKONG plastic shredders utilize advanced cutting technology with high-torque motors and precision-engineered blades. The shredding process begins when plastic waste enters the cutting chamber, where rotating blades grip and slice the material against stationary knives. This shearing action continues until the plastic pieces are small enough to pass through a sizing screen, ensuring consistent output size for further processing or direct reuse.

Need a Customized Shredding Solution?

Our experts can help you determine the right shredder for your specific plastic waste challenges.

Request a Consultation

Benefits of Using MAIKONG Plastic Shredder Machines

Investing in a quality industrial plastic waste shredder delivers multiple advantages for businesses in the Philippines:

Economic Benefits

- Significant reduction in waste disposal costs

- Creation of valuable recyclable material from waste

- Decreased need for purchasing virgin plastic materials

- Lower transportation costs through volume reduction

- Potential new revenue stream from selling processed materials

Operational Benefits

- Efficient processing of high volumes of plastic waste

- Consistent output size for optimal recycling

- Reduced storage space requirements for waste

- Improved workplace organization and cleanliness

- Enhanced sustainability credentials for your business

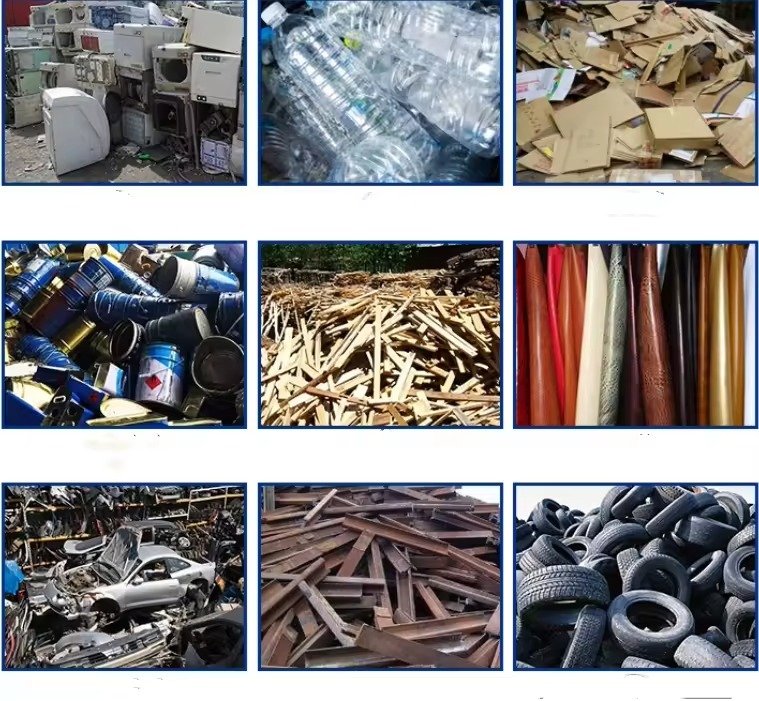

Types of Plastic Waste Handled by MAIKONG Shredders

MAIKONG industrial plastic shredders are engineered to process a wide range of plastic materials commonly found in Philippine manufacturing and consumer waste streams:

Thermoplastics

- #1 PET (Polyethylene Terephthalate) – Bottles, containers

- #2 HDPE (High-Density Polyethylene) – Pipes, crates, totes

- #4 LDPE (Low-Density Polyethylene) – Films, bags

- #5 PP (Polypropylene) – Containers, automotive parts

- #6 PS (Polystyrene) – Packaging, disposable items

Industrial Plastic Waste

- Production purge and start-up lumps

- Injection molding runners and rejects

- Extrusion and blow molding waste

- Thermoforming trim and off-cuts

- Quality control rejects and overruns

Post-Consumer Plastics

- Plastic bottles and containers

- Packaging materials and films

- Agricultural plastics and films

- Automotive plastic components

- Electronic device housings

MAIKONG Industrial Plastic Shredder Types

We offer several types of shredders designed to meet different plastic recycling requirements:

| Shredder Type |

Best For |

Key Features |

Ideal Applications |

| Single-Shaft Shredders |

General plastic waste, high volume |

High torque, low speed, versatile |

Production waste, bulk materials |

| Double-Shaft Shredders |

Tough, bulky materials |

Counter-rotating shafts, high shearing force |

Thick-walled plastics, large containers |

| Four-Shaft Shredders |

Precise size reduction |

Uniform output size, efficient cutting |

When specific particle size is required |

| Granulators |

Secondary shredding |

High-speed cutting, fine output |

Creating regrind for direct reuse |

Find Your Ideal Shredder Solution

Browse our complete range of industrial plastic shredders to find the perfect match for your waste processing needs.

Explore Our Products

Applications in Philippine Industries

MAIKONG industrial plastic waste shredders serve diverse sectors across the Philippines:

Manufacturing Applications

- Plastic Product Manufacturing – Reclaiming production waste and rejects

- Packaging Industry – Processing film scraps and packaging waste

- Automotive Manufacturing – Recycling plastic components and trim waste

- Electronics Manufacturing – Processing plastic housings and components

Recycling Applications

- Recycling Facilities – Processing post-consumer plastic waste

- Waste Management Companies – Volume reduction and material recovery

- Agricultural Sector – Recycling irrigation pipes and agricultural films

- Municipal Waste Processing – Handling community plastic waste

How to Select the Right Industrial Plastic Waste Shredder

Choosing the optimal shredder for your operation depends on several key factors:

Material Considerations

- Types of plastic to be processed

- Material hardness and thickness

- Presence of contaminants

- Required throughput capacity

- Desired output particle size

Operational Factors

- Available space for installation

- Power supply limitations

- Noise restrictions

- Maintenance capabilities

- Integration with existing systems

Business Requirements

- Initial investment budget

- Operating cost considerations

- Return on investment timeline

- Future expansion plans

- Regulatory compliance needs

Not Sure Which Shredder You Need?

Our experts can analyze your specific requirements and recommend the perfect solution.

Contact via WhatsApp

Customization and Add-ons for MAIKONG Shredding Systems

We offer various customization options to enhance your plastic shredder machine performance:

Input and Feeding Systems

- Conveyor Feeding – Automated material infeed via belt or screw conveyor

- Hydraulic Ram – Force-feeds difficult materials into cutting chamber

- Hopper Extensions – Increased capacity for bulky materials

- Crane-Loading Configurations – For handling large or heavy items

Output and Collection Systems

- Discharge Conveyors – Automated material removal

- Cyclone Collection – Pneumatic transport of shredded material

- Bagging Systems – Direct packaging of processed material

- Integration with Granulators – Complete processing solutions

Technical Customizations

Cutting Systems

- Specialized rotor designs

- Custom knife configurations

- Hardened blade options

- Adjustable cutting gaps

Drive Systems

- Hydraulic drive options

- Variable frequency drives

- Enhanced motor power

- Energy-efficient configurations

Control Systems

- PLC automation

- Remote monitoring capabilities

- Production data logging

- Integrated safety features

Maintenance and Support for Your Industrial Plastic Shredder

Proper maintenance ensures optimal performance and longevity of your MAIKONG shredder:

Routine Maintenance

- Regular blade inspection and rotation

- Lubrication of moving components

- Cleaning of cutting chamber and screens

- Inspection of drive system components

- Checking and tightening of fasteners

MAIKONG Support Services

- Comprehensive operator training

- Preventive maintenance programs

- Rapid response technical support

- Genuine plastic shredder parts supply

- Equipment optimization consultations

Need Replacement Parts or Service?

Keep your shredder running at peak performance with genuine MAIKONG parts and expert service.

Order Replacement Parts

MAIKONG Product Range

We offer a comprehensive selection of shredding solutions to meet diverse requirements:

Industrial Plastic Shredders

Our flagship heavy-duty shredders designed for continuous operation in demanding environments. Available in various sizes with throughput capacities from 500 kg/h to 5000+ kg/h.

Small Plastic Shredders

Compact yet powerful solutions for smaller operations or specialized applications. Perfect for businesses with moderate volume requirements or space constraints.

Mini Plastic Shredder Machines

Entry-level solutions for businesses beginning their recycling journey or processing limited volumes of plastic waste with specific material requirements.

Success Stories from Philippine Businesses

Manufacturing Facility in Manila

A leading plastic products manufacturer implemented a MAIKONG double-shaft industrial plastic waste shredder to process production waste. Results included:

- 85% reduction in waste disposal costs

- Recovery of 2.5 tons of reusable material monthly

- ROI achieved within 14 months

- Improved sustainability credentials

Recycling Operation in Cebu

A recycling company installed a MAIKONG single-shaft industrial plastic waste shredder to process post-consumer plastic waste. Benefits included:

- Processing capacity increased by 40%

- More consistent output quality

- Reduced maintenance downtime

- Expanded material handling capabilities

Transform Your Plastic Waste Management Today

An industrial plastic waste shredder from MAIKONG represents more than just equipment—it’s a comprehensive solution for turning plastic waste challenges into opportunities. By implementing our advanced shredding technology, your Philippine business can reduce costs, enhance sustainability, and potentially create new revenue streams from what was once considered waste.

With decades of experience in plastic processing technology and a commitment to customer success, MAIKONG stands ready to be your trusted partner in plastic waste management. Contact us today to begin your journey toward more efficient, sustainable, and profitable plastic waste processing.

Discover the MAIKONG Difference

Join the growing number of Philippine businesses that have transformed their plastic waste management with MAIKONG technology.

Learn More About MAIKONG