In today’s competitive Philippine manufacturing and recycling sectors, energy efficiency has become a critical factor in operational success. Industrial shredders represent significant power consumers in plastic processing facilities, making their energy performance a key consideration for businesses looking to optimize costs. MAIKONG, a leading manufacturer of high-performance shredding equipment, has pioneered innovations that deliver exceptional energy efficiency without compromising processing power. This comprehensive guide examines how MAIKONG’s energy-efficient industrial shredders can transform your plastic recycling operations while significantly reducing electricity consumption and operational expenses.

Why Energy Efficiency is Critical for Industrial Shredders in the Philippines

MAIKONG industrial shredder with energy monitoring system in a Philippine recycling facility

The Philippines faces unique energy challenges that make efficiency particularly important. With electricity costs among the highest in Southeast Asia, Philippine businesses must carefully manage power consumption to remain competitive. Industrial shredders typically consume substantial electricity, especially when processing tough materials like hard plastics or contaminated waste streams.

Did you know? Philippine industrial electricity rates average ₱8-10 per kWh, significantly higher than neighboring countries. An energy-efficient industrial shredder can reduce operational costs by 25-40% compared to conventional models.

Beyond cost considerations, energy efficiency aligns with the Philippines’ sustainability goals and growing environmental regulations. As the country implements stricter waste management policies, businesses that adopt energy-efficient recycling equipment gain both operational advantages and regulatory compliance benefits.

Rising Energy Costs

Philippine businesses face some of the highest electricity rates in Asia. Energy-efficient industrial shredders can significantly reduce operational expenses, improving profitability and competitiveness.

Environmental Regulations

The Philippines continues to strengthen environmental policies. Energy-efficient equipment helps meet compliance requirements while supporting corporate sustainability initiatives.

Grid Reliability Challenges

Power interruptions remain common in many Philippine regions. Energy-efficient machinery places less strain on electrical systems and backup power sources during unstable grid conditions.

Carbon Footprint Reduction

Lower energy consumption directly translates to reduced carbon emissions, supporting the Philippines’ climate commitments and improving corporate environmental profiles.

Understanding Energy Efficiency Ratings for Plastic Shredder Machines

Energy efficiency ratings for industrial shredders involve several standardized metrics that help businesses compare performance across different models and manufacturers. Understanding these ratings is essential for making informed purchasing decisions that balance initial investment with long-term operational costs.

Comparative energy efficiency ratings across MAIKONG industrial shredder models

| Efficiency Metric |

Description |

MAIKONG Standard |

Industry Average |

| kWh per Ton |

Energy consumed to process one ton of material |

15-22 kWh/ton |

30-45 kWh/ton |

| Power Factor |

Ratio of real power to apparent power |

0.92-0.95 |

0.75-0.85 |

| Standby Power |

Energy consumed when idle |

0.5-1.2 kW |

2.5-4.0 kW |

| Start-up Energy |

Power surge during machine startup |

2.5x operating load |

4x operating load |

| Motor Efficiency Class |

International efficiency classification |

IE3/IE4 |

IE1/IE2 |

Key Components Affecting Efficiency in MAIKONG Industrial Shredders

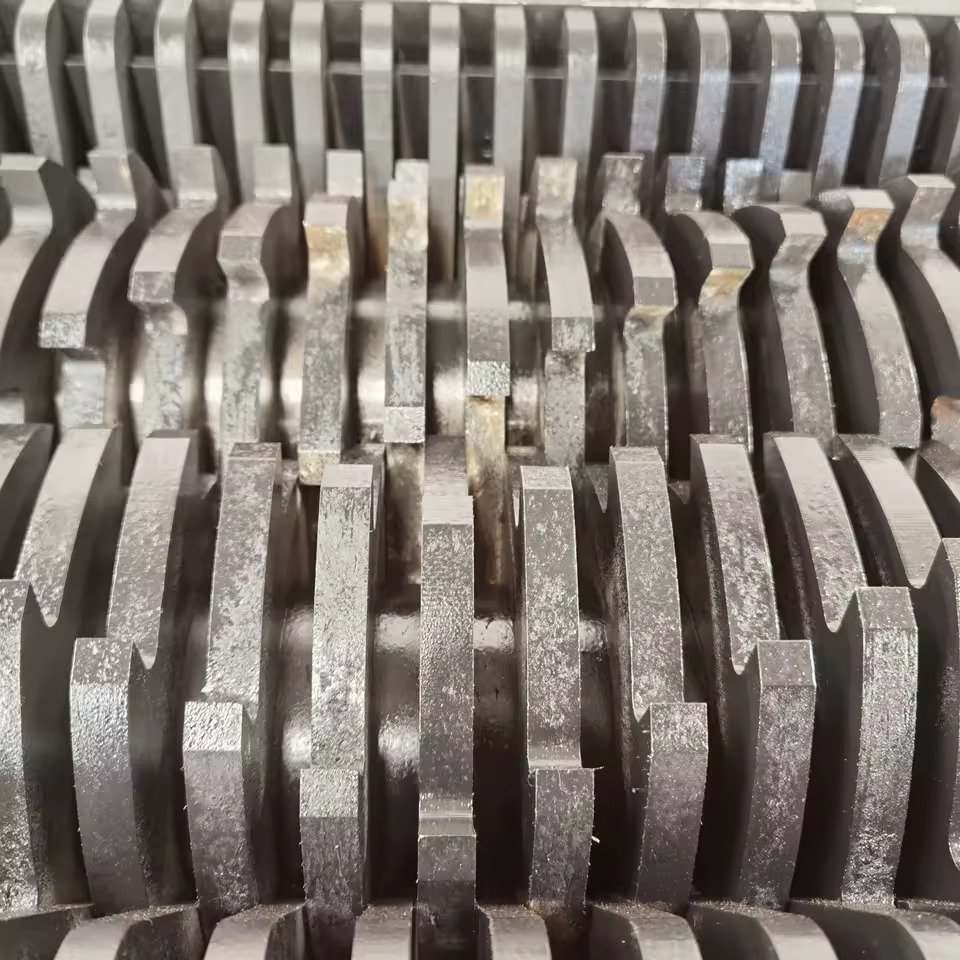

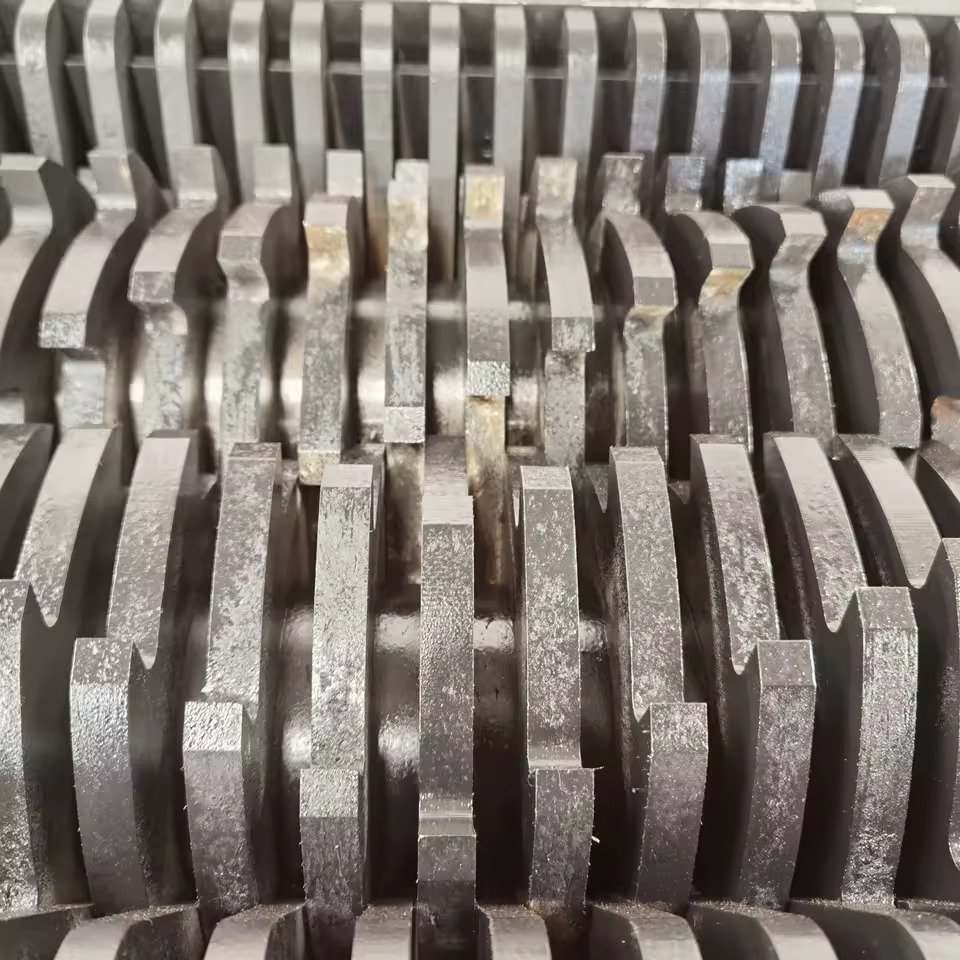

Cutaway view highlighting energy-efficient components in MAIKONG shredders

- Drive System Design: MAIKONG utilizes advanced direct-drive systems that eliminate efficiency losses associated with belt drives and gearboxes, achieving up to 15% energy savings.

- Cutting Chamber Geometry: Optimized cutting chamber designs reduce material resistance and improve flow, minimizing energy requirements while maintaining throughput.

- Blade Technology: Precision-engineered blades with specialized metallurgy maintain sharpness longer, reducing the energy needed for cutting operations.

- Control Systems: Intelligent control systems adjust power consumption based on material load, preventing energy waste during variable processing conditions.

- Regenerative Capabilities: Advanced models incorporate regenerative braking that captures energy during deceleration phases and feeds it back into the system.

Motor Technology: The Heart of an Efficient Plastic Crusher Machine

The motor represents the single most important component affecting energy efficiency in industrial shredders. MAIKONG exclusively uses premium-efficiency motors that exceed international standards for industrial equipment.

Premium-efficiency IE4 class motor used in MAIKONG industrial shredders

Premium Efficiency Classifications

MAIKONG shredders utilize motors meeting IE3 (Premium Efficiency) and IE4 (Super Premium Efficiency) standards, delivering significant energy savings compared to conventional IE1 or IE2 motors commonly used in competing equipment.

Variable Frequency Drives

All MAIKONG industrial shredders incorporate advanced VFD technology that optimizes motor performance based on load conditions, reducing energy consumption during partial-load operation by up to 30%.

Soft-Start Technology

Integrated soft-start systems reduce initial power surges, decreasing stress on electrical infrastructure and lowering peak demand charges that significantly impact Philippine industrial electricity bills.

Thermal Management

Advanced cooling systems maintain optimal motor temperatures, preventing efficiency losses and extending component lifespan even in challenging Philippine climate conditions.

MAIKONG’s Approach to Building Energy-Efficient Industrial Plastic Shredders

MAIKONG’s engineering philosophy centers on maximizing energy efficiency without compromising performance. This approach integrates multiple technologies and design principles to create industrial shredders that deliver exceptional value throughout their operational lifecycle.

MAIKONG engineering team optimizing shredder designs for energy efficiency at GD, SZ facility

Low-Speed, High-Torque Rotor Design

One of MAIKONG’s signature innovations is the low-speed, high-torque rotor system that fundamentally transforms the energy profile of industrial shredders. This approach delivers multiple efficiency advantages while enhancing overall performance.

MAIKONG’s precision-engineered low-speed high-torque rotor system

Energy Consumption Benefits

The low-speed approach reduces friction and heat generation, allowing the system to operate with 25-40% less energy compared to high-speed alternatives while maintaining equivalent throughput capacity.

Reduced Wear and Maintenance

Lower operational speeds significantly extend component lifespan, reducing maintenance frequency and associated downtime costs that impact overall operational efficiency.

Consistent Processing Performance

High-torque design ensures consistent cutting force even when processing challenging materials, preventing the energy spikes and inefficiencies that occur when conventional shredders encounter resistance.

Noise and Heat Reduction

The low-speed operation generates significantly less noise and heat, creating better working conditions and reducing cooling requirements that would otherwise increase energy consumption.

Premium Electrical Components for Sustained Performance

MAIKONG exclusively uses industrial-grade electrical components from world-leading manufacturers to ensure optimal energy efficiency throughout the shredder’s operational life.

Industrial-grade electrical control system in MAIKONG shredders

- Schneider Electric and Siemens Components: Premium contactors, relays, and circuit protection devices minimize electrical losses and ensure reliable operation.

- Advanced PLC Systems: Programmable logic controllers optimize operational parameters in real-time, adjusting power consumption based on material characteristics.

- High-Efficiency Transformers: Custom-designed power supply systems minimize conversion losses throughout the electrical system.

- Premium Cabling and Connections: Oversized conductors and high-quality connection points reduce resistance and associated energy losses.

- Intelligent Power Management: Automated systems detect and eliminate unnecessary power consumption during idle periods and between processing cycles.

Discover MAIKONG’s Energy-Efficient Shredding Solutions

Our engineering team can help you select the ideal industrial shredder configuration for your specific materials and throughput requirements while optimizing energy efficiency.

Explore Industrial Shredders

Contact via WhatsApp

Comparing Efficiency Across the MAIKONG Product Line

MAIKONG offers a comprehensive range of industrial shredders with varying energy efficiency profiles designed to meet different operational requirements and budget considerations.

MAIKONG’s comprehensive industrial shredder product line with varying efficiency ratings

Industrial Plastic Shredder vs. Mini Plastic Shredder Machine: Power vs. Precision

Industrial-Scale Shredders

Industrial plastic shredders deliver maximum throughput for high-volume operations. While consuming more total energy, their efficiency per ton of processed material is optimized through advanced engineering and scale advantages.

- Processing capacity: 500-2000 kg/hour

- Energy consumption: 30-75 kWh

- Efficiency ratio: 15-22 kWh per ton

Mini Shredders

Mini plastic shredder machines offer precision processing for smaller operations. Their compact design and specialized engineering deliver excellent energy efficiency for lower-volume applications.

- Processing capacity: 50-300 kg/hour

- Energy consumption: 5-15 kWh

- Efficiency ratio: 18-25 kWh per ton

Comparative energy consumption analysis across MAIKONG shredder product line

The Role of Plastic Shredder Parts in Maintaining Peak Efficiency

Even the most energy-efficient shredder design requires proper maintenance and quality replacement parts to maintain optimal performance. MAIKONG’s engineered plastic shredder parts are designed to preserve energy efficiency throughout the equipment’s operational life.

Precision-engineered MAIKONG replacement parts maintain optimal energy efficiency

- Precision-Engineered Blades: MAIKONG replacement blades maintain optimal cutting geometry and edge quality, preventing the increased power consumption associated with dull or improperly aligned cutting elements.

- High-Performance Bearings: Premium bearings reduce friction and associated energy losses while extending component lifespan.

- Optimized Screens: Properly sized and maintained discharge screens ensure material flows efficiently through the system without unnecessary recirculation that increases energy consumption.

- Specialized Seals and Gaskets: High-quality seals prevent material leakage that can cause jams and efficiency losses.

- Genuine Electronic Components: Original MAIKONG control system parts maintain the precise operational parameters necessary for optimal energy efficiency.

“Regular maintenance using genuine MAIKONG parts typically improves energy efficiency by 15-20% compared to machines using generic replacement components. This translates to significant operational savings over the equipment’s lifetime.”

– MAIKONG Engineering Team, GD, SZ

Calculating ROI: How Efficient Shredders Lower Operational Costs

Investing in energy-efficient industrial shredders delivers substantial return on investment through multiple cost-saving mechanisms. Understanding these savings helps Philippine businesses make informed purchasing decisions that consider total ownership costs rather than just initial acquisition price.

ROI analysis for MAIKONG energy-efficient shredders in Philippine operations

| Cost Factor |

Conventional Shredder |

MAIKONG Energy-Efficient Shredder |

5-Year Savings (PHP) |

| Energy Consumption |

₱950,000/year |

₱570,000/year |

₱1,900,000 |

| Maintenance Costs |

₱320,000/year |

₱180,000/year |

₱700,000 |

| Downtime Losses |

₱450,000/year |

₱180,000/year |

₱1,350,000 |

| Component Replacement |

₱280,000/year |

₱150,000/year |

₱650,000 |

| Total Operational Costs |

₱2,000,000/year |

₱1,080,000/year |

₱4,600,000 |

Philippine Energy Cost Calculation Example: A typical industrial shredder operating 8 hours daily, 5 days weekly, consumes approximately 45,000 kWh annually. At Philippine industrial electricity rates of ₱9.50/kWh, MAIKONG’s 40% efficiency improvement saves approximately ₱171,000 annually in direct energy costs alone.

Direct Energy Savings

MAIKONG’s efficient plastic shredders reduce electricity consumption by 30-40% compared to conventional alternatives, delivering immediate and continuous cost savings throughout the equipment’s operational life.

Reduced Maintenance Costs

Energy-efficient designs typically experience less mechanical stress and heat generation, extending component lifespan and reducing maintenance frequency and associated costs.

Lower Peak Demand Charges

Soft-start technology and optimized power management reduce peak electricity demand, helping Philippine businesses avoid the substantial premium charges associated with high instantaneous power consumption.

Extended Equipment Lifespan

MAIKONG’s energy-efficient designs typically deliver 25-40% longer operational lifespans, extending the return period on capital investment and reducing lifetime equipment costs.

Calculate Your Potential Savings with MAIKONG

Our technical team can provide a detailed ROI analysis based on your specific operational parameters and local energy costs in the Philippines.

Request ROI Analysis

Email for Consultation

Applications of Efficient Shredding in Philippine Plastic Waste Management

Energy-efficient industrial shredders play a crucial role in addressing the Philippines’ growing plastic waste challenges while supporting sustainable business operations. MAIKONG’s solutions are optimized for the specific requirements of various Philippine industries.

MAIKONG industrial shredder processing post-consumer plastic in a Philippine recycling facility

Municipal Waste Management

MAIKONG industrial shredders help Philippine municipalities process increasing volumes of plastic waste while minimizing energy costs that impact public budgets.

Manufacturing Scrap Recovery

Philippine manufacturers use MAIKONG shredders to efficiently process production scrap for recycling, reducing waste disposal costs while recovering valuable materials.

Recycling Operations

Dedicated recycling businesses throughout the Philippines rely on energy-efficient MAIKONG equipment to maintain profitable operations despite rising energy costs.

Packaging Industry

Philippine packaging manufacturers use small plastic shredders to process production waste and incorporate recycled content into new products.

Agricultural Applications

Agricultural operations process plastic mulch, containers, and irrigation components using energy-efficient shredders to manage waste responsibly.

Post-Consumer Collection

Community recycling initiatives use MAIKONG equipment to process collected consumer plastics while minimizing operational costs through energy efficiency.

“Energy efficiency has become the decisive factor in our equipment selection process. With Philippine electricity costs continuing to rise, MAIKONG’s efficient shredders have reduced our processing costs by nearly 35%, making our recycling operation economically sustainable.”

– Operations Manager, Manila Recycling Enterprise

Choosing the Right MAIKONG Shredder for Your Energy Needs

Selecting the optimal industrial shredder requires balancing processing requirements with energy efficiency considerations. MAIKONG offers comprehensive consultation to help Philippine businesses identify the most suitable equipment configuration.

MAIKONG technical consultation for industrial shredder selection in the Philippines

What factors should I consider when evaluating energy efficiency?

Key considerations include your specific material type (hardness, density, contamination level), required throughput capacity, duty cycle (hours of operation), local electricity costs, and available power infrastructure. MAIKONG’s technical team evaluates these factors to recommend the most energy-efficient configuration for your specific application.

How do I determine the right size shredder for optimal energy efficiency?

Oversized shredders waste energy during normal operation, while undersized units struggle with material loads, causing inefficiency and premature wear. MAIKONG conducts material testing to determine the ideal size that balances throughput requirements with energy efficiency, ensuring you don’t purchase more capacity than needed.

What energy efficiency features should I prioritize for Philippine operations?

For Philippine facilities, prioritize features that address local challenges: soft-start technology to manage unstable power conditions, high-efficiency motors to minimize consumption given high electricity rates, and advanced cooling systems designed for tropical climates. MAIKONG’s equipment is optimized for Southeast Asian operating conditions.

Benefits of Energy-Efficient Shredders

- Lower operational costs through reduced electricity consumption

- Decreased maintenance requirements and extended equipment lifespan

- Reduced environmental impact and carbon footprint

- Improved processing consistency and product quality

- Enhanced compliance with emerging energy efficiency regulations

Considerations When Upgrading

- Higher initial investment compared to standard equipment

- May require electrical infrastructure assessment

- Operator training needed to maximize efficiency benefits

- Maintenance procedures specific to high-efficiency components

- Potential adaptation period for existing workflows

MAIKONG Energy Efficiency Rating

4.8

Excellent

Control System Optimization

4.9/5

Mechanical Efficiency

4.6/5

Embracing Energy Efficiency for Sustainable Plastic Processing

As Philippine industries face increasing pressure to reduce operational costs and environmental impact, energy-efficient industrial shredders represent a critical investment in sustainable business operations. MAIKONG’s commitment to engineering excellence delivers equipment that significantly reduces energy consumption while maintaining exceptional processing performance.

By selecting MAIKONG’s energy-efficient shredding solutions, Philippine businesses gain a competitive advantage through reduced operational costs, improved processing capabilities, and enhanced environmental performance. Contact our team today to discover how our technology can transform your plastic processing operations.

Visit Our Website for More Information

Explore our complete range of energy-efficient industrial shredders and learn more about MAIKONG’s commitment to sustainable plastic processing solutions.

Visit MAIKONG Website

About MAIKONG