What is a Mini Plastic Shredder and Why is it Essential for Philippine Businesses?

MAIKONG’s mini plastic shredder designed specifically for the Philippine market

A mini plastic shredder is a compact machine designed to reduce various plastic materials into smaller, uniform pieces for recycling or disposal. These machines are particularly valuable in the Philippines, where space constraints and moderate volume requirements are common challenges for many businesses.

Despite their compact size, MAIKONG mini plastic shredders deliver impressive performance, efficiently processing various plastic materials into recyclable pieces. Their space-efficient design makes them ideal for facilities with limited floor area, a common concern for many Philippine businesses.

Need Technical Assistance?

Our experts are available to answer your questions about mini plastic shredder specifications and applications.

How Plastic Waste is Generated in Philippine Industries

Understanding how plastic waste is generated helps businesses identify the best recycling solutions. In the Philippines, plastic waste comes from various sources:

Manufacturing Processes

- Thermoforming: Improper tuning of machines creates plastic lumps

- Injection molding: Runners, purges, trims, and rejects generate significant plastic scraps

- Mold switching and masterbatch changes produce substantial waste

- Production interruptions often result in plastic lumps

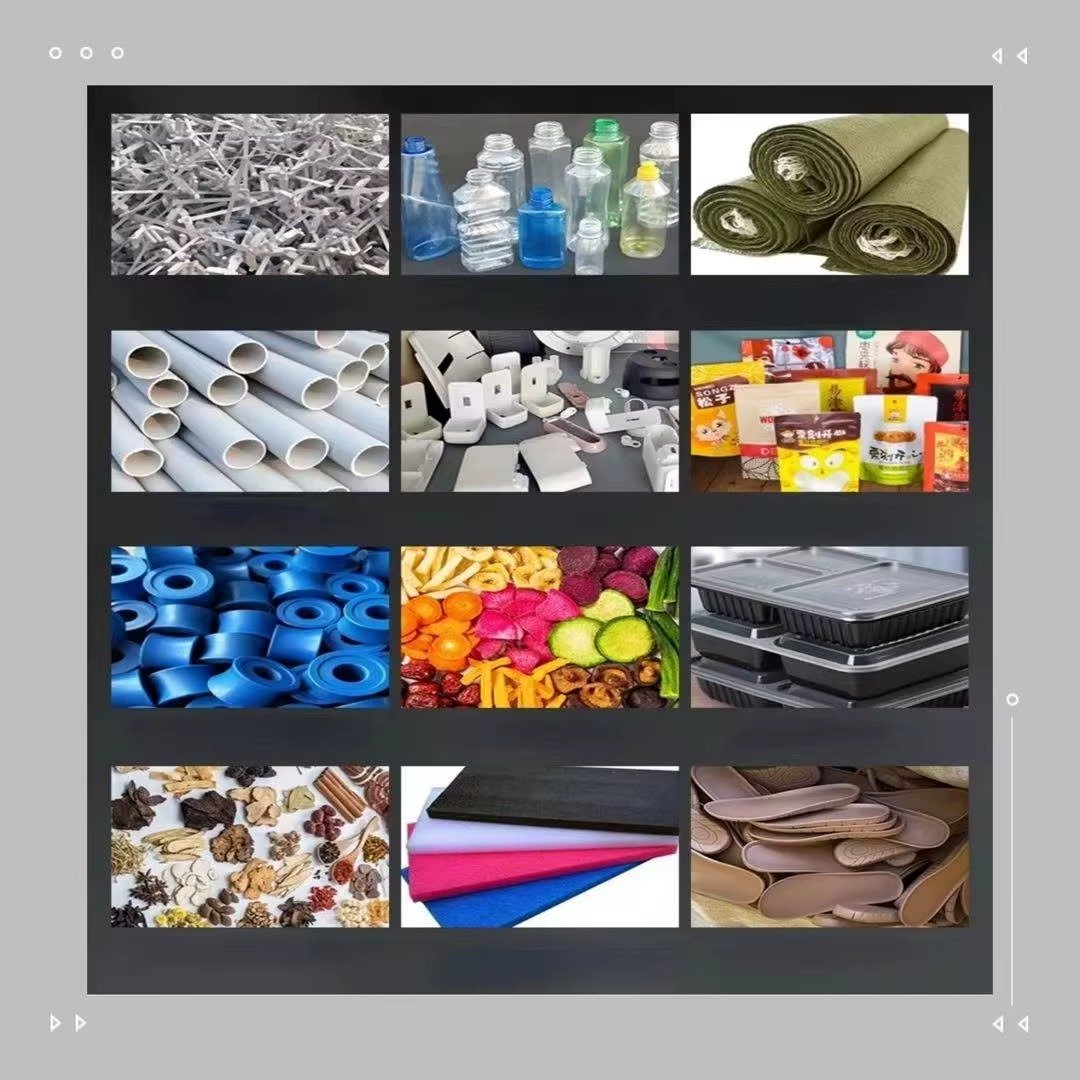

Common Plastic Waste Types

- PET bottles and containers (common in beverage industry)

- HDPE plastic products (buckets, containers, pipes)

- PP sheets and packaging materials

- Plastic films and bags (LDPE)

- Industrial plastic waste and production scraps

Common plastic waste types in Philippine industries that benefit from mini plastic shredder processing

The Economic and Environmental Benefits of On-Site Shredding for Philippine Companies

Benefits of Using a Mini Plastic Shredder

- Reduced waste disposal costs through volume reduction

- Creation of valuable recycled material that can be sold or reused

- Lower transportation expenses for waste removal

- Compliance with environmental regulations in the Philippines

- Enhanced corporate sustainability profile

- Space efficiency with compact equipment footprint

- Energy efficiency with optimized motor technology

Challenges Without Proper Shredding

- High waste disposal costs for unprocessed materials

- Excessive storage space required for bulky waste

- Missed revenue opportunities from recyclable materials

- Potential non-compliance with Philippine environmental regulations

- Increased carbon footprint from waste transportation

- Difficulty implementing sustainable business practices

With the growing plastic waste challenge in the Philippines, practical and affordable solutions are essential. MAIKONG’s mini plastic shredder machines are designed specifically to help local businesses implement effective recycling programs without major infrastructure investments.

MAIKONG’s Range of Plastic Shredding Solutions for the Philippines

MAIKONG has established itself as a premier manufacturer of plastic recycling equipment. Based in SZ, GD, we specialize in designing and producing high-quality mini plastic shredder solutions that meet the diverse needs of businesses throughout the Philippines.

MAIKONG’s complete range of plastic shredder machines for Philippine businesses

Deep Dive: MAIKONG Mini Plastic Shredder Machine

Our mini plastic shredder machine is designed specifically for businesses with space constraints or moderate volume requirements. Despite its compact size, these machines deliver impressive performance, efficiently processing various plastic materials into uniform, recyclable pieces.

Space-Efficient Design

Optimized dimensions for small to medium workspaces, making it ideal for facilities with limited floor area in the Philippines.

Versatile Application

Perfect for processing various plastic types including PET bottles, plastic films, containers, and industrial plastic waste common in Philippine manufacturing.

Energy Efficiency

Engineered with advanced motor technology to minimize power consumption while maintaining optimal shredding performance.

Find Your Perfect Mini Plastic Shredder

Our team is standing by to help you select the ideal model for your specific needs in the Philippines.

Comparing MAIKONG Small Plastic Shredder vs. Industrial Models

| Feature | Mini Plastic Shredder | Small Plastic Shredder | Industrial Plastic Shredder |

| Motor Power | 3-7.5 kW | 7.5-15 kW | 15-90 kW |

| Output Capacity | 50-200 kg/h | 150-500 kg/h | 500-3000 kg/h |

| Hopper Size | 300×250 – 500×400 mm | 500×400 – 600×500 mm | 600×500 – 1500×1200 mm |

| Ideal Application | Small businesses, schools, small recycling centers | Medium businesses, manufacturing facilities | Large recycling plants, major manufacturing |

| Space Requirements | Minimal (fits in small workspaces) | Moderate | Substantial |

Size comparison of MAIKONG plastic shredder models available in the Philippines

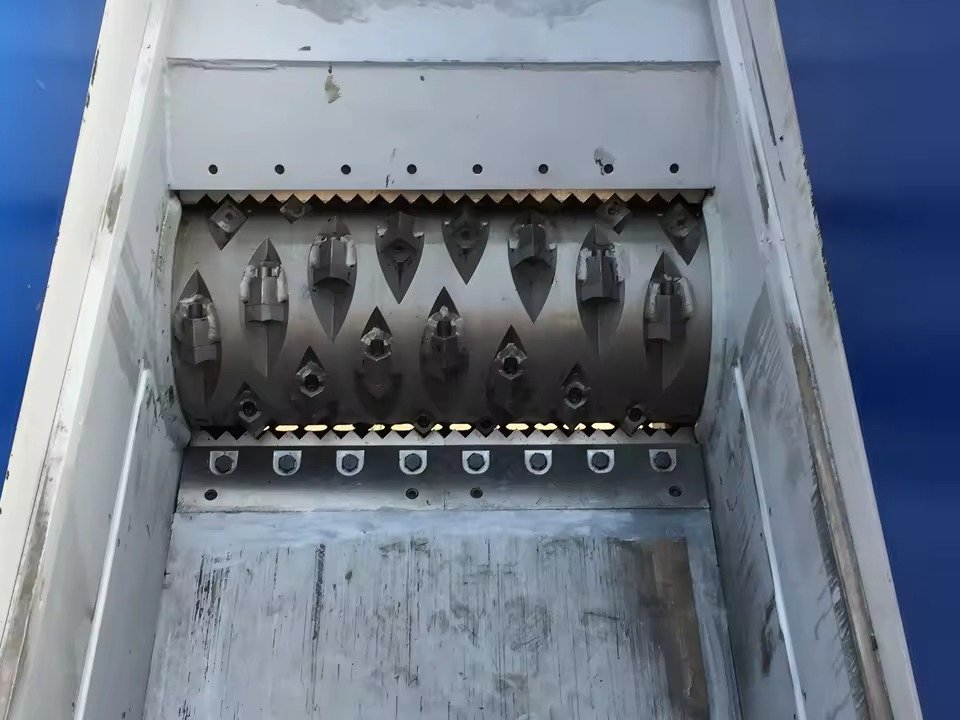

Understanding Plastic Shredder Parts for Maintenance and Longevity

Proper maintenance is essential for ensuring the longevity and optimal performance of your mini plastic shredder. Understanding the key components and their maintenance requirements will help you maximize your investment.

Key components of MAIKONG mini plastic shredder requiring regular maintenance

Essential Maintenance Tasks

- Regular blade inspection and rotation/replacement

- Bearing lubrication according to schedule

- Drive system checks and adjustments

- Cleaning of cutting chamber and screens

- Inspection of electrical components and connections

Common Replacement Parts

- Cutting blades (rotating and stationary)

- Screens for output size control

- Bearings and seals

- Drive belts or couplings

- Electrical components

MAIKONG provides comprehensive maintenance guidelines with each machine and offers quick access to genuine replacement parts to minimize downtime. Our technical team is available via WhatsApp for immediate assistance with any maintenance questions.

Technical Guide: Choosing the Right Shredder for Common Philippine Plastic Waste

Shredding Different Plastic Types in the Philippines

MAIKONG mini plastic shredder processing various plastic types common in the Philippines

| Plastic Type | Common Examples in Philippines | Recommended Shredder Model | Special Considerations |

| PET (#1) | Beverage bottles, food containers | MK-MS200 | May require pre-crushing for large volumes |

| HDPE (#2) | Plastic totes, buckets, containers | MK-MS200/MK-MS300 | Thicker material requires more power |

| PVC (#3) | Pipes, window trim, siding | MK-MS300 | Requires special blade configuration |

| LDPE (#4) | Plastic films, bags, flexible packaging | MK-MS100 | Special rotor design for flexible materials |

| PP (#5) | Containers, caps, trays, automotive parts | MK-MS200 | Versatile processing, minimal special requirements |

Key Features and Customizations of MAIKONG Shredders

Infeed Systems

- Belt conveyor for continuous feeding

- Screw conveyor for controlled material flow

- Inclined chute for forklift or crane loading

- Vertical ram for force-feeding materials

Output Collection

- Cyclone collection with blower system

- Belt conveyor for direct transfer

- Screw conveyor for controlled discharge

- Collection bins for batch processing

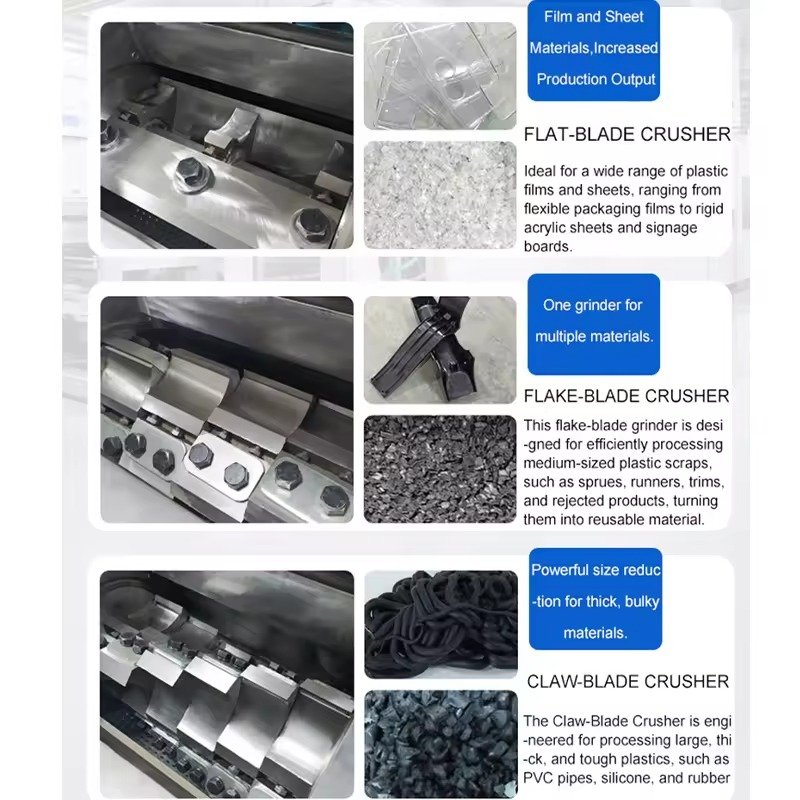

Rotor Types

- Standard rotor for general applications

- Special design for plastic films/flexible materials

- Heavy-duty rotor for challenging materials

- Custom configurations for specific needs

Customization options available for MAIKONG mini plastic shredder philippines models

All MAIKONG mini plastic shredder machines can be customized to meet specific requirements. Additional options include elevated racks for integration with other equipment, increased motor power, hydraulic motor options, and specialized shredding chambers for oversized items.

Need a Customized Solution?

Our engineering team can design a mini plastic shredder tailored to your specific requirements.

Applications of Mini Plastic Shredders Across Philippine Sectors

The mini plastic shredder philippines market has unique requirements that MAIKONG machines are specifically designed to address. Our shredders serve various sectors throughout the country.

MAIKONG mini plastic shredder in operation at a Philippine recycling center

Recycling Centers & Junkshops

Small to medium recycling facilities and junkshops throughout the Philippines benefit from our compact shredders. These businesses process community plastic waste into valuable recyclable material, creating additional revenue streams while supporting environmental initiatives.

Before and after: Plastic waste processed by MAIKONG mini plastic shredder

Small-Scale Manufacturing & Injection Molding

Manufacturing facilities across the Philippines use our shredders to process production scrap and reduce waste disposal costs. By recycling plastic waste on-site, these businesses support sustainability initiatives while improving their bottom line.

Schools, Communities, and Local Government Units (LGUs)

Educational institutions and community recycling programs use MAIKONG mini plastic shredders for teaching recycling technologies and implementing sustainable waste management practices. Local government units find these machines ideal for municipal waste reduction programs.

“The growing plastic waste challenge in the Philippines requires practical, affordable solutions. Our mini plastic shredder machines are designed specifically to help local businesses implement effective recycling programs without major infrastructure investments.”

Frequently Asked Questions About Mini Plastic Shredders in the Philippines

What types of plastic can a mini plastic shredder machine process?

MAIKONG mini plastic shredders can process a wide range of plastics including PET, HDPE, LDPE, PP, PS, and ABS. They’re suitable for bottles, containers, films, bags, and various plastic scraps common in the Philippines. The blade configuration can be optimized for specific material types to ensure efficient processing.

How does a mini plastic shredder differ from a granulator?

While both reduce plastic size, mini plastic shredders typically operate at lower speeds with higher torque to handle larger pieces and tougher materials. Granulators run at higher speeds to produce smaller, more uniform particles. Shredders are often used as the first stage in a two-stage size reduction process, with granulators used for the final size reduction.

What maintenance is required for a mini plastic shredder?

Regular maintenance includes blade inspection and rotation/replacement, bearing lubrication, drive system checks, and cleaning of the cutting chamber and screens. MAIKONG provides detailed maintenance schedules and guidelines with each machine and offers technical support via WhatsApp for immediate assistance.

What is the typical output size from your mini plastic shredder machines?

Output size is determined by the screen used in the machine. Our standard machines typically produce shredded material between 10-30mm, but custom screen sizes are available to achieve specific output requirements for Philippine recycling operations.

How much does a mini plastic shredder cost in the Philippines?

The cost varies depending on specifications, capacity, and customization requirements. MAIKONG offers competitive factory-direct pricing specifically for the Philippine market. For an accurate quote based on your specific needs, contact our sales team via WhatsApp or email.

MAIKONG technical support providing maintenance guidance for mini plastic shredder customers

Enhance Your Plastic Recycling Capabilities with MAIKONG Mini Plastic Shredders

MAIKONG’s mini plastic shredder machines offer the perfect combination of compact design, powerful performance, and reliability for businesses throughout the Philippines. With competitive pricing, customization options, and dedicated support, we’re committed to helping you implement effective plastic recycling solutions.

MAIKONG mini plastic shredder philippines contributing to sustainable waste management

Ready to Transform Your Plastic Waste Management?

Discover how our mini plastic shredder machine can revolutionize your approach to plastic recycling.

Contact Information:

Email: Lucy@plasticshredder.ph

Phone/WhatsApp: 008613-51090-74-01

Website: https://plasticshredder.ph