In the demanding world of plastic recycling, not all waste materials yield easily to processing. When facing tough industrial plastics, high volumes, or contaminated waste streams, standard shredding equipment often falls short. Four-shaft plastic shredders represent the pinnacle of shredding power, designed specifically for applications where maximum force and efficiency are non-negotiable. MAIKONG’s advanced four-shaft technology delivers the muscle needed for the most challenging plastic recycling scenarios in the Philippines.

What is a Four-Shaft Plastic Shredder and How Does It Deliver Maximum Power?

Four-shaft plastic shredders represent the heavy artillery in plastic waste processing. Unlike their single or double-shaft counterparts, these machines employ a sophisticated cutting system with four synchronized shafts working in concert to process the most challenging materials.

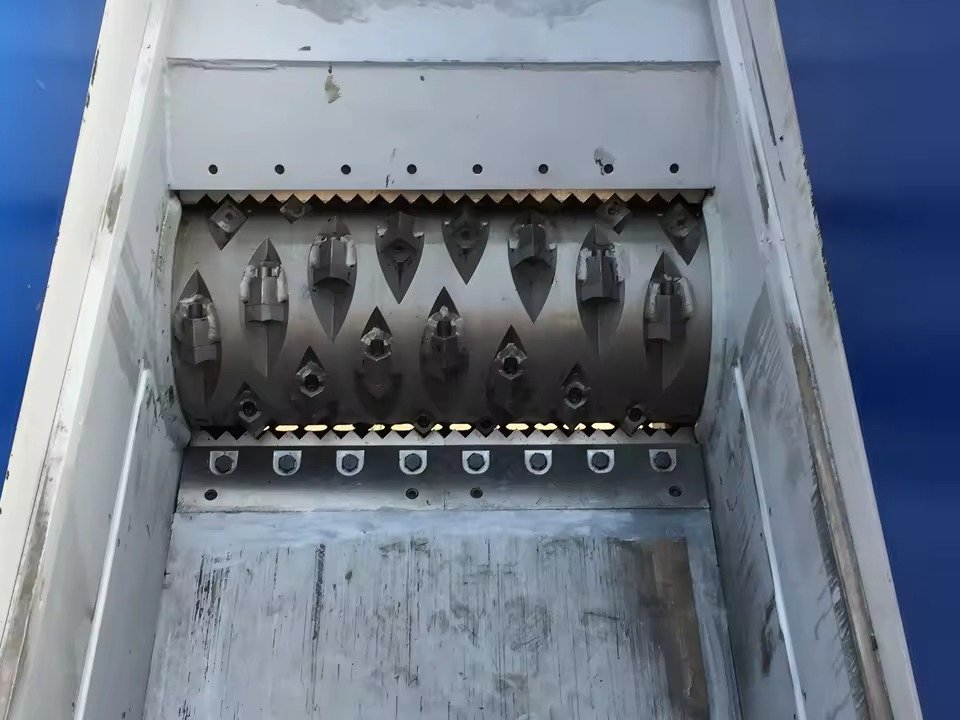

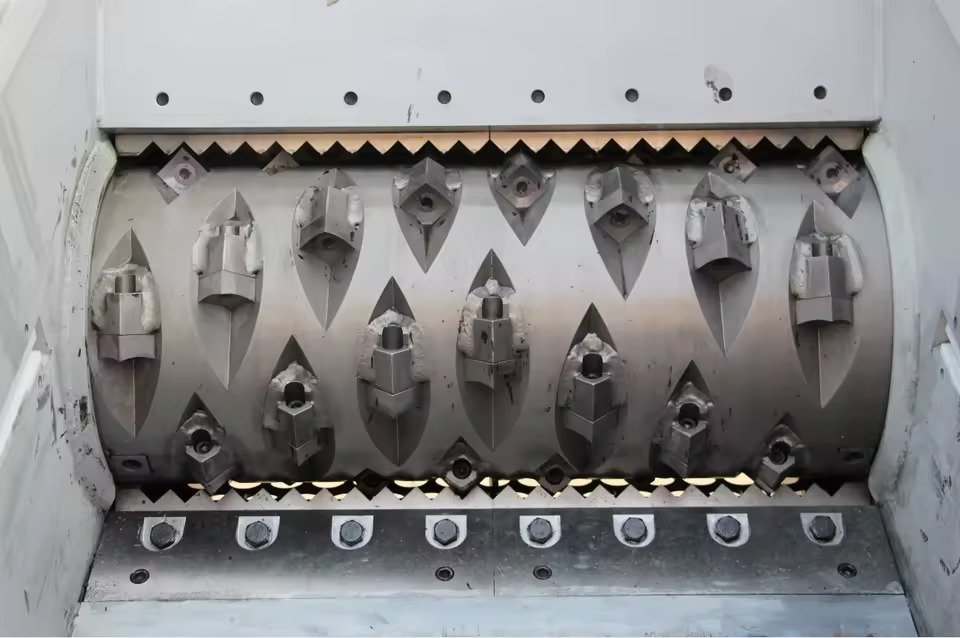

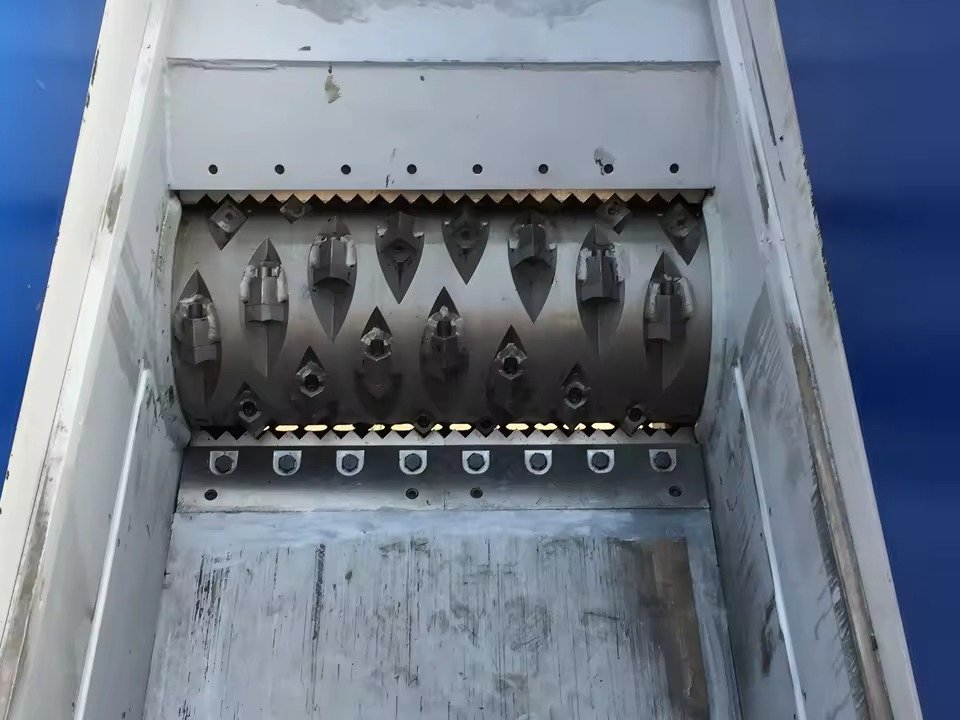

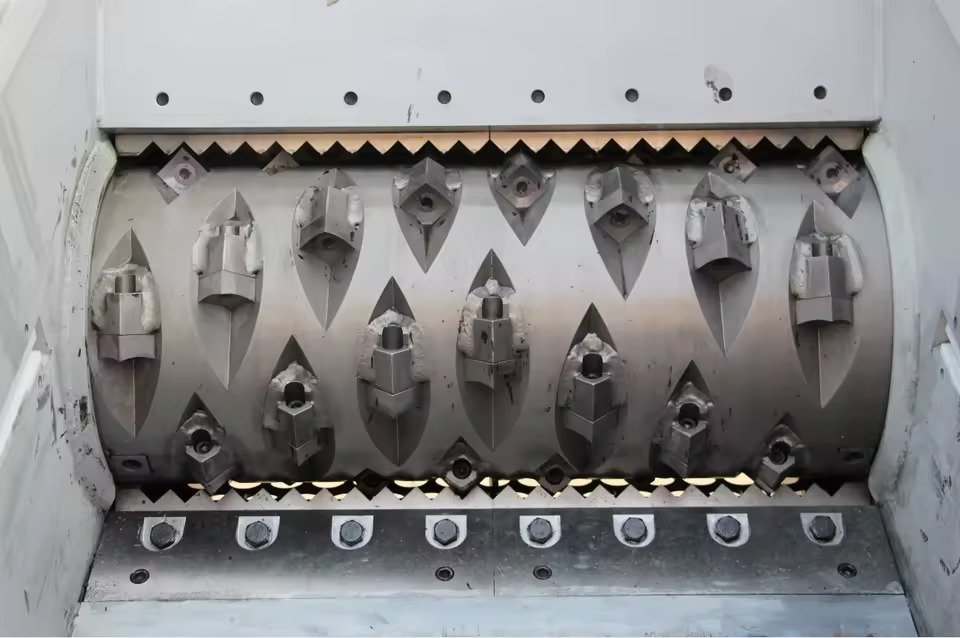

MAIKONG’s four-shaft cutting system delivers unmatched shredding power

The Engineering Behind MAIKONG’s Four-Shaft Design

The four-shaft design creates a powerful shearing action that few materials can resist. The primary shafts grip and pull materials in, while the secondary shafts create a cross-cutting action that produces uniformly sized output. This configuration generates tremendous torque, allowing MAIKONG plastic shredder machines to process materials that would stall or damage lesser equipment.

| Technical Feature |

Benefit |

| Quad-shaft synchronized cutting |

Eliminates material jamming and ensures continuous operation |

| High-torque gearbox system |

Maintains cutting force even with dense materials |

| Hardened steel alloy blades |

Extended service life even when processing contaminated plastics |

| Independent shaft drive motors |

Optimized power distribution for maximum efficiency |

| Automatic load sensing |

Adjusts power delivery based on material resistance |

Comparing Shafts: Single, Double, and the Superiority of Four

Understanding the differences between shredder types helps identify when a four-shaft system is necessary:

Four-Shaft Advantages

- Handles the toughest materials including reinforced plastics

- Produces consistent particle size without screening

- Processes high volumes continuously without overheating

- Effectively handles contaminated waste streams

- Reduced maintenance downtime compared to other high-power options

When Four-Shaft May Be Excessive

- Processing only clean, soft plastic films

- Very low volume operations

- Limited space facilities where compact equipment is required

- Applications where ultra-fine granulation is the primary goal

Key Scenarios Demanding a Maximum Power Plastic Shredder

Not every plastic recycling operation requires the substantial power of a four-shaft shredder. However, certain scenarios make these robust machines not just beneficial but essential for efficient operations.

Processing Large, Dense Plastic Lumps and Purges

Manufacturing processes like injection molding, thermoforming, and extrusion regularly produce substantial plastic purges and start-up lumps. These dense masses of hardened plastic resist processing in standard shredders but yield readily to MAIKONG’s four-shaft plastic shredder technology.

MAIKONG four-shaft shredders easily process dense plastic purges that stall lesser machines

Handling Mixed and Contaminated Industrial Plastic Waste

Industrial waste streams rarely contain pure, clean plastics. Metal fasteners, labels, dirt, and mixed plastic types create challenging processing conditions. Four-shaft plastic shredders from MAIKONG power through these mixed materials without jamming or excessive wear.

“When processing post-consumer plastic waste with unpredictable contaminants, our MAIKONG four-shaft shredder has eliminated the frequent jams and downtime we experienced with our previous equipment.”

– Manila Recycling Operations Manager

High-Volume, Continuous Operation Requirements

Commercial recycling facilities processing tons of plastic daily need equipment that won’t become a bottleneck. MAIKONG’s industrial-grade four-shaft plastic shredders maintain consistent throughput even under demanding 24/7 operation schedules.

Shredding Reinforced Plastics, Composites, and Bulky Items

Fiber-reinforced plastics, composite materials, and bulky items like plastic pallets or automotive components demand exceptional cutting force. The quad-shaft design excels with these materials where other shredders struggle or fail completely.

Not Sure If You Need Four-Shaft Power?

Our engineers can analyze your specific materials and volume requirements to recommend the ideal solution.

Request Material Assessment

Technical Specifications and Features of High-Power Shredders

Understanding the technical aspects of four-shaft plastic shredders helps in selecting the right equipment for your specific needs.

Motor Power and Drive Systems from MAIKONG

MAIKONG’s four-shaft shredders feature independent motors for each shaft pair, with total power ranging from 45kW to 160kW depending on the model. This distributed power system ensures optimal torque delivery exactly where needed.

MAIKONG’s advanced motor and gearbox system delivers exceptional torque

Blade Technology and Cutting Chamber Design

The heart of any shredder is its cutting system. MAIKONG’s four-shaft models feature:

- Precision-machined hardened steel blades with specialized geometry

- Customizable blade configurations for different material types

- Easily accessible cutting chamber for maintenance

- Wear-resistant chamber linings to extend equipment life

- Adjustable cutting gap to optimize output size

Control Systems and Safety Features

Modern industrial plastic shredders require sophisticated control systems to operate efficiently and safely. MAIKONG’s four-shaft models include:

Intelligent Controls

- PLC-based operation system

- Automatic load sensing and adjustment

- Programmable operation sequences

- Remote monitoring capabilities

Safety Systems

- Emergency stop functions

- Automatic shutdown on foreign object detection

- Overload protection

- Enclosed cutting chamber with safety interlocks

Advanced control systems ensure safe, efficient operation

MAIKONG’s Four-Shaft Shredder Solutions for the Philippine Market

MAIKONG has developed specialized four-shaft plastic shredder solutions to address the unique challenges faced by recycling operations in the Philippines.

Model Range and Capacity Guide

MAIKONG offers a comprehensive range of four-shaft shredders to match different operational requirements:

| Model |

Working Width |

Motor Power |

Throughput Capacity |

Ideal Application |

| MK-FS800 |

800mm |

2×37kW |

1-2 tons/hour |

Medium-sized recycling operations |

| MK-FS1000 |

1000mm |

2×45kW |

2-3 tons/hour |

Large commercial recyclers |

| MK-FS1200 |

1200mm |

2×55kW |

3-4 tons/hour |

Industrial plastic manufacturers |

| MK-FS1600 |

1600mm |

2×75kW |

4-6 tons/hour |

High-volume waste management |

MAIKONG’s industrial-scale four-shaft shredders handle high volumes efficiently

Integration with MAIKONG’s Other Equipment

For complete plastic recycling solutions, MAIKONG’s four-shaft shredders integrate seamlessly with our other processing equipment:

Complete recycling solutions with integrated MAIKONG equipment

- Primary shredding with four-shaft technology

- Secondary granulation with MAIKONG plastic grinder systems

- Washing and separation lines for contaminated materials

- Conveying and material handling systems

- Complete plant design and installation services

Ready to Upgrade Your Plastic Processing Capability?

MAIKONG offers customized four-shaft solutions for the Philippine market.

Contact via WhatsApp

The ROI of Investing in a Maximum Power Plastic Shredder

While four-shaft plastic shredders represent a significant investment, their return on investment can be substantial for the right applications.

Cost Savings from Efficient On-Site Recycling

On-site recycling with a powerful four-shaft shredder delivers multiple financial benefits:

Direct Cost Savings

- Reduced waste disposal fees

- Lower transportation costs

- Decreased virgin material purchases

- Potential revenue from selling processed materials

Operational Benefits

- Increased processing capacity

- Reduced downtime from equipment jams

- Lower maintenance costs compared to underpowered equipment

- Extended equipment lifespan with proper sizing

Typical ROI timeline for MAIKONG four-shaft shredder investment

Enhancing Your Recycling Business Capability

Beyond direct cost savings, a four-shaft plastic shredder machine can transform your business capabilities:

- Process materials competitors cannot handle

- Accept more diverse waste streams

- Offer higher-value processing services

- Scale operations without proportional labor increases

- Meet increasingly stringent environmental regulations

“Our MAIKONG four-shaft shredder paid for itself within 14 months through reduced disposal costs and new revenue streams from previously unprocessable materials.”

– Cebu Plastic Recycling Facility Manager

Choosing the Right MAIKONG Shredder for Your Needs

MAIKONG offers a complete range of plastic shredders to match every application and budget. Understanding when to choose each type ensures optimal performance and value.

When a Mini Plastic Shredder Machine or Small Plastic Shredder Suffices

Not every operation requires the power of a four-shaft system. MAIKONG’s mini plastic shredder machines and small plastic shredders are ideal for:

MAIKONG mini plastic shredders for lighter-duty applications

- Small-scale operations with limited space

- Processing clean, soft plastics like films and packaging

- Low-volume production waste recycling

- Laboratory or testing applications

- Educational or demonstration purposes

The Role of Industrial Plastic Shredders and Four-Shaft Models

For demanding commercial and industrial applications, MAIKONG’s industrial plastic shredders and four-shaft models deliver the necessary performance:

MAIKONG industrial four-shaft shredders handle the toughest recycling challenges

- High-volume commercial recycling operations

- Processing contaminated or mixed waste streams

- Handling tough materials like reinforced plastics

- Applications requiring precise particle size control

- 24/7 continuous operation environments

Sourcing Genuine Plastic Shredder Parts for Longevity

Maintaining optimal performance requires genuine plastic shredder parts. MAIKONG provides:

Genuine MAIKONG replacement parts ensure optimal performance

- Factory-certified replacement blades and wear components

- Comprehensive maintenance kits

- Upgraded components for older machines

- Fast shipping throughout the Philippines

- Technical support for installation and maintenance

Need Expert Guidance?

Our technical team can help determine the ideal shredder configuration for your specific materials and volume requirements.

Email Our Specialists

Maximizing Your Plastic Recycling Success with MAIKONG

When your plastic recycling operation demands maximum power, MAIKONG’s four-shaft plastic shredders deliver the performance, reliability, and efficiency needed to process even the most challenging materials. From tough industrial purges to high-volume mixed waste streams, our advanced shredding technology transforms plastic waste challenges into profitable opportunities.

As the Philippines continues to address growing plastic waste management needs, MAIKONG stands ready with locally-supported solutions backed by global expertise. Our team in GD, SZ provides comprehensive sales, service, and support throughout the Philippine market.

Ready to Power Up Your Plastic Recycling?

Contact MAIKONG today to discuss your specific requirements and discover the ideal four-shaft solution for your operation.

MAIKONG provides comprehensive support throughout the Philippines