Understanding the technical terminology associated with plastic shredders is crucial for making informed purchasing decisions in the recycling industry. Whether you’re new to plastic recycling or looking to upgrade your current equipment, this comprehensive glossary will help you navigate the complex world of plastic shredding technology. As a leading manufacturer based in GD, SZ, MAIKONG is committed to providing Philippine buyers with the knowledge and tools necessary for successful plastic recycling operations.

Core Machine Types and Their Definitions

What is a Plastic Shredder?

A plastic shredder is a mechanical device designed to reduce the size of plastic materials by cutting, tearing, or breaking them into smaller pieces. These machines are fundamental to plastic recycling processes, waste management, and material recovery operations. MAIKONG offers a diverse range of shredders designed to handle various plastic types and volumes, from small workshop units to industrial-scale systems.

MAIKONG’s advanced plastic shredder with precision cutting technology

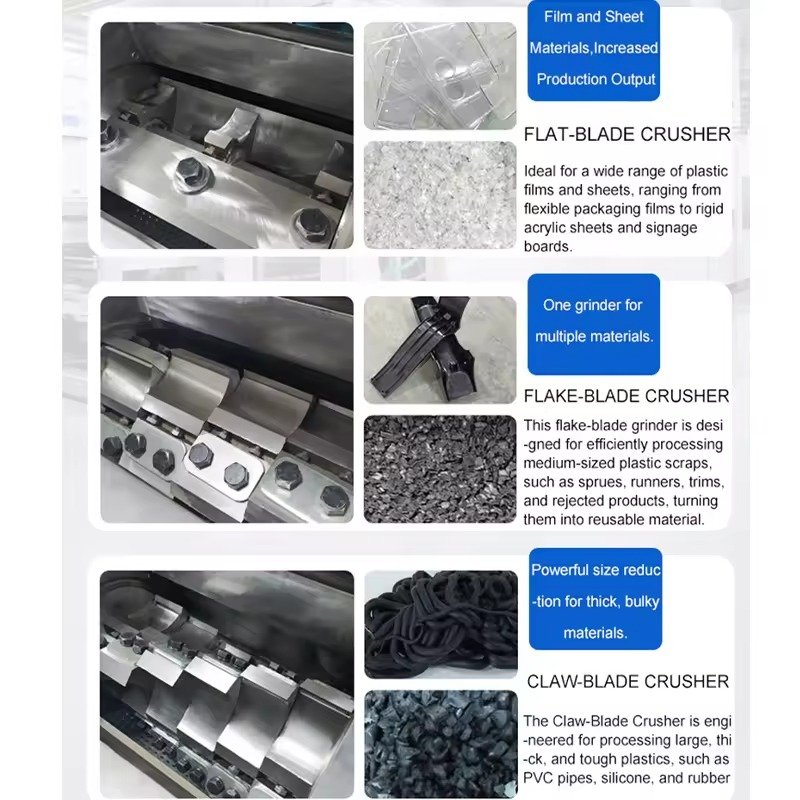

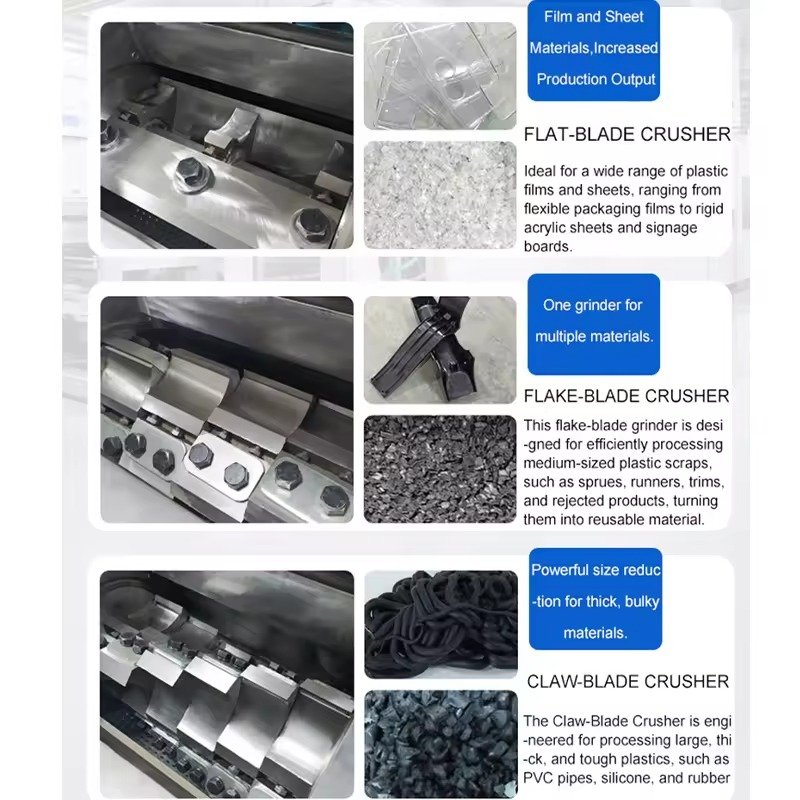

Plastic Shredder Machine vs. Grinder vs. Crusher

While often used interchangeably, these terms refer to distinct equipment with specific functions:

- Plastic Shredder Machine: Designed for primary size reduction of larger plastic materials using low-speed, high-torque cutting action with rotating blades. Typically produces particles in the 10-50mm range.

- Plastic Grinder: Used for secondary size reduction after shredding, operating at higher speeds with specialized cutting chambers to produce smaller, more uniform particles (typically 3-10mm).

- Plastic Crusher Machine: Primarily used for breaking brittle plastics through impact rather than cutting. Often employed for specific materials like acrylic or rigid PVC.

Industrial Plastic Shredder

An industrial plastic shredder is a heavy-duty machine designed for high-volume commercial and manufacturing applications. These robust systems feature powerful motors (typically 45-132kW), reinforced cutting chambers, and specialized blade configurations to process large quantities of plastic waste efficiently. MAIKONG’s industrial models incorporate advanced safety features, automated feeding systems, and customizable output options to meet specific production requirements.

High-capacity industrial plastic shredder for commercial recycling operations

Mini Plastic Shredder Machine & Small Plastic Shredder

Compact versions designed for lower-volume applications:

Mini Plastic Shredder Machine

The smallest category of shredders, typically featuring motors under 5kW and processing capacities of 50-100kg/hour. These units are ideal for small workshops, laboratories, and educational settings. MAIKONG’s mini shredders offer the same cutting technology as larger models but in a space-efficient design.

Explore Mini Shredders

Small Plastic Shredder

Mid-range units with motors typically between 5-15kW and processing capacities of 100-300kg/hour. These versatile machines are suitable for small to medium businesses, recycling centers, and manufacturing facilities with moderate waste volumes.

View Small Shredders

Plastic Bottle Shredder

Specialized shredders designed specifically for processing plastic bottles and containers. These machines feature unique blade configurations and feeding mechanisms optimized for hollow, thin-walled items like PET bottles, HDPE containers, and similar packaging materials. MAIKONG’s bottle shredders incorporate anti-jamming technology and specialized cutting chambers to handle the unique challenges of bottle processing.

Need guidance selecting the right shredder for your application?

Our experts can help you determine which MAIKONG model best suits your specific plastic recycling needs in the Philippines.

Contact via WhatsApp: 008613-51090-74-01

Key Components and Plastic Shredder Parts

Understanding the critical components of a plastic shredder is essential for proper operation, maintenance, and troubleshooting. MAIKONG designs each component with durability and performance in mind.

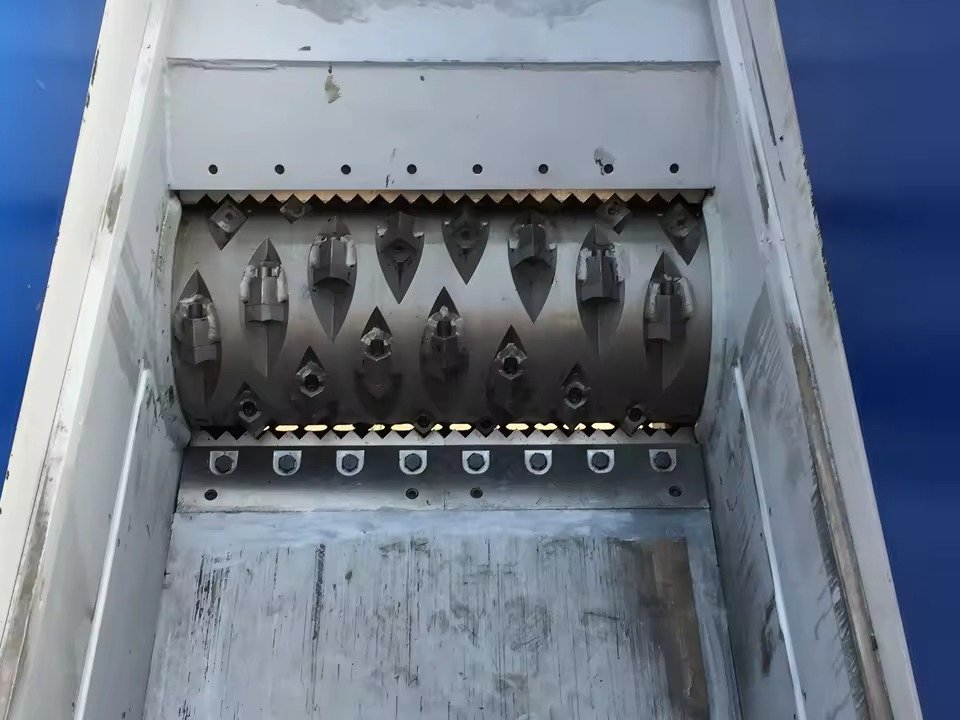

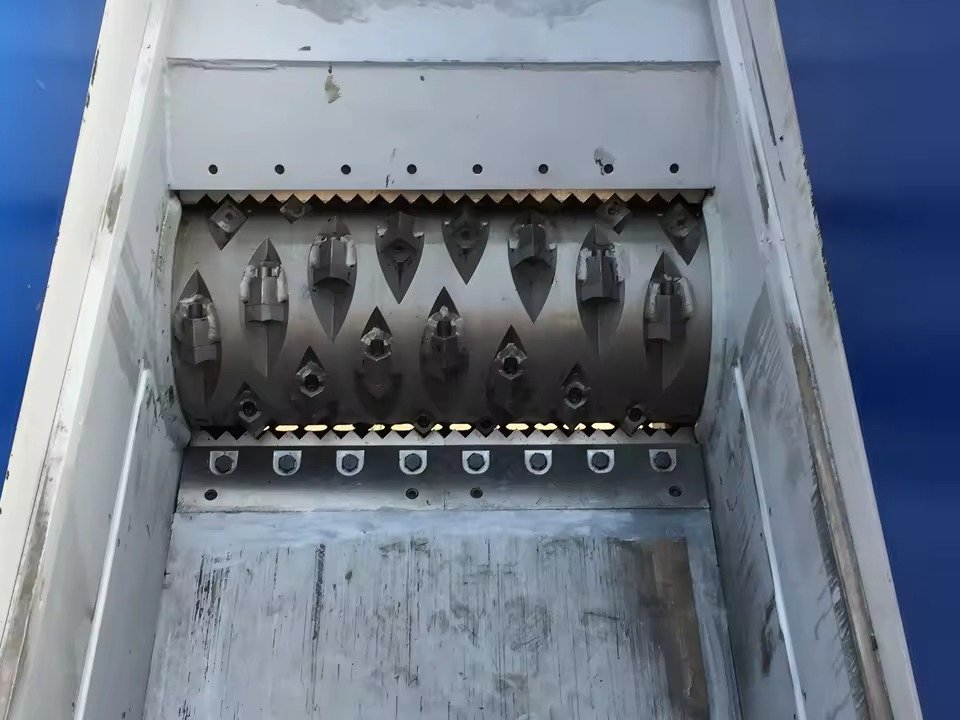

Detailed breakdown of essential plastic shredder parts in a MAIKONG machine

Shredder Rotor (Types: Standard, Film, Heavy-Duty)

The rotor is the heart of any plastic shredder, consisting of a shaft with mounted cutting elements that rotate to engage and cut the material. MAIKONG offers three specialized rotor types:

Standard Rotor

Versatile design suitable for most common plastics including PET, HDPE, and PP. Features evenly spaced cutting elements with moderate tooth configurations.

Film Rotor

Specialized for processing thin, flexible materials like plastic films, bags, and sheets. Incorporates closer blade spacing and specialized hook designs to prevent material wrapping.

Heavy-Duty Rotor

Reinforced design for challenging materials such as thick-walled pipes, solid lumps, and contaminated plastics. Features hardened alloy construction and aggressive tooth profiles.

Cutting Blades (Alloy, Design, Replaceable)

The cutting blades are the primary wear components in any shredder system. MAIKONG utilizes specialized alloy steel blades with the following characteristics:

- Material Composition: High-carbon, high-chromium tool steel with hardness ratings of 56-62 HRC for optimal wear resistance.

- Blade Designs: Available in configurations with 2, 3, or 7 teeth depending on the application requirements and material properties.

- Reversible Design: Most MAIKONG blades can be rotated or flipped to expose fresh cutting edges, extending service life.

- Replaceable Inserts: Modular blade systems allow for replacement of individual cutting elements rather than entire assemblies.

MAIKONG’s specialized cutting blades with different tooth configurations

Shredding Chamber

The shredding chamber is the enclosed area where the cutting action occurs. Key aspects include:

- Chamber Construction: Typically made from welded steel plate with reinforced wear areas.

- Screen/Filter: Perforated plates or mesh screens that control output particle size by retaining material until sufficiently reduced.

- Pusher Mechanisms: Hydraulic or mechanical systems that force material against the cutting rotor.

- Access Points: Service doors and maintenance access designed for safe blade changes and cleaning.

Drive System (Motor, Reducer)

The drive system provides the power and torque necessary for effective shredding:

Electric Motors

MAIKONG shredders utilize industrial-grade electric motors ranging from 3kW for mini models to 132kW for large industrial units. Motor selection is based on application requirements, material characteristics, and throughput needs.

Reduction Systems

Gearboxes or hydraulic drives that convert the high-speed, low-torque output of electric motors into the low-speed, high-torque rotation required for effective shredding. MAIKONG employs precision-engineered reduction systems with ratios typically between 20:1 and 50:1.

Control System (PLC, Electrical Panel)

Modern plastic shredder machines incorporate sophisticated control systems:

- PLC Controls: Programmable Logic Controllers that manage operation sequences, monitor system parameters, and provide safety interlocks.

- Overload Protection: Systems that detect excessive load and automatically reverse or stop the rotor to prevent damage.

- User Interface: Control panels with intuitive displays for operation, adjustment, and monitoring.

- Remote Monitoring: Advanced MAIKONG models offer connectivity options for remote diagnostics and operation tracking.

Need replacement parts for your plastic shredder?

MAIKONG offers a complete range of high-quality replacement parts compatible with most major shredder brands in the Philippines market.

Explore Replacement Parts

Process and Application Terminology

Shredding vs. Granulating

Understanding the distinction between these processes is essential for designing effective recycling systems:

| Process |

Equipment |

Typical Output Size |

Applications |

| Shredding |

Plastic Shredder |

10-50mm |

Primary size reduction, volume reduction, preparation for further processing |

| Granulating |

Plastic Grinder |

3-10mm |

Secondary processing, production of uniform regrind for extrusion or molding |

| Pulverizing |

Pulverizer/Mill |

0.5-3mm |

Fine powder production for rotational molding, compounding |

Visual comparison of plastic material before shredding, after shredding, and after granulating

Common Plastic Feedstocks (Lumps, Purges, Runners, Post-Consumer Waste)

Plastic shredders process various forms of plastic waste, each with unique handling requirements:

- Purges and Lumps: Solid masses of plastic generated during production startups, color changes, or machine cleaning. These dense materials often require heavy-duty shredders with high torque.

- Runners and Sprues: Excess plastic from injection molding processes. Typically homogeneous and clean, making them ideal for direct recycling.

- Rejected Parts: Manufactured items that fail quality control. Usually consistent in composition but variable in size and shape.

- Post-Consumer Waste: Used plastic products collected after consumer use. Often contaminated and mixed, requiring specialized handling and sorting.

- Industrial Packaging: Items like pallets, crates, and containers from commercial/industrial sources. Generally larger and thicker than consumer packaging.

Plastic Resin Types (HDPE, LDPE, PP, PVC, PET) and Shredding Considerations

Different plastic types present unique challenges for shredding operations:

| Resin Type |

Common Applications |

Shredding Characteristics |

Special Considerations |

| HDPE (#2) |

Bottles, containers, pipes, crates |

Moderate hardness, good processability |

Minimal blade wear, standard rotor configuration effective |

| LDPE/LLDPE (#4) |

Films, bags, flexible packaging |

Soft, elastic, tendency to wrap around rotors |

Requires specialized film rotors, cooling may be necessary |

| PP (#5) |

Containers, automotive parts, furniture |

Moderate hardness, good processability |

Standard configurations effective, moderate wear rates |

| PVC (#3) |

Pipes, profiles, construction materials |

Abrasive, potential for chlorine release |

Accelerated blade wear, potential corrosion issues, ventilation needed |

| PET (#1) |

Bottles, food containers, fiber |

Hard, abrasive, potential for dust generation |

Higher wear rates, dust collection recommended |

Various plastic types being processed with MAIKONG shredding equipment

Not sure which shredder is right for your plastic type?

Our technical team can recommend the optimal MAIKONG configuration based on your specific material mix and production requirements in the Philippines.

Email Our Experts

System Add-ons and Customization

Modern plastic shredder systems can be enhanced with various accessories and modifications to improve efficiency, safety, and versatility. MAIKONG offers numerous customization options to tailor systems to specific operational requirements.

Infeed Systems (Conveyor, Chute, Vertical Pusher)

Mechanisms that facilitate material loading into the shredder:

- Conveyor Infeed: Belt or chain conveyors that transport material to the shredder at controlled rates. Ideal for continuous operation and integration with sorting lines.

- Inclined Chutes: Gravity-fed loading systems that allow material to slide into the cutting chamber. Suitable for manual loading operations.

- Vertical Pushers: Hydraulic ram systems that force material against the cutting rotor. Essential for processing bulky or lightweight materials that might otherwise “float” above the rotor.

- Bin Tippers: Mechanical systems that lift and empty collection bins directly into the shredder hopper.

MAIKONG industrial shredder with automated conveyor infeed system

Output Collection (Cyclone, Conveyor)

Systems for managing processed material after shredding:

Pneumatic Transport

Blower and cyclone systems that use air to move shredded material to collection points or subsequent processing equipment. Provides efficient transport while also cooling the material.

Output Conveyors

Belt or screw conveyors positioned beneath the shredder to collect and transport processed material. Available in various configurations to match facility layout and subsequent processing requirements.

Safety and Containment Features (Lid, Elevated Rack)

Elements that enhance operational safety and material control:

- Safety Lids and Covers: Mechanical or interlocked covers that prevent access to moving parts during operation while containing potential material ejection.

- Elevated Mounting Frames: Structural supports that position shredders at optimal heights for integration with other equipment or collection systems.

- Dust Collection Systems: Extraction equipment that captures and removes airborne particles generated during the shredding process.

- Sound Enclosures: Acoustic barriers that reduce operational noise levels for improved workplace conditions.

Essential safety features on MAIKONG plastic shredder systems

Technical Specifications and Selection Criteria

Throughput Capacity

The amount of material a shredder can process in a given time period, typically measured in kilograms per hour (kg/h). Capacity varies based on:

- Motor Power: Higher power generally correlates with increased throughput.

- Material Properties: Density, thickness, and composition affect processing rates.

- Rotor Design: Blade configuration and rotor diameter influence efficiency.

- Screen Size: Smaller output sizes require longer processing time, reducing throughput.

Output Particle Size

The dimensions of processed material after shredding, controlled by:

Screen Selection

Perforated plates with specific hole diameters that retain material until it’s reduced to the desired size. MAIKONG offers screens ranging from 8mm to 100mm depending on application requirements.

Blade Configuration

The number, spacing, and design of cutting elements affect the initial cut size before material encounters the screen. Closer blade spacing generally produces smaller initial particles.

Various screen sizes available for MAIKONG plastic shredders

Machine Models and Dimensions

MAIKONG offers a comprehensive range of plastic shredder models to accommodate various application requirements:

| Model |

Blade Diameter |

Motor Power |

Dimensions (L×W×H mm) |

Typical Applications |

| MK-600 |

220mm |

11kW×2-15kW×2 |

2500×1100×1600 |

Small workshops, light-duty recycling |

| MK-800 |

300mm |

18.5kW×2-22kW×2 |

3000×1400×1800 |

Medium production facilities, recycling centers |

| MK-1000 |

400mm |

45kW×2 |

3900×1800×2200 |

Industrial recycling, high-volume processing |

| MK-1400 |

500mm |

55kW×2 |

4700×2100×2400 |

Large industrial operations, continuous processing |

| MK-2000 |

650mm |

132kW×2 |

6500×2500×2800 |

Heavy-duty industrial recycling, bulk processing |

Size comparison of MAIKONG plastic shredder models from mini to industrial scale

The MAIKONG Advantage for the Philippine Market

As a leading manufacturer of plastic shredder technology, MAIKONG offers unique advantages specifically tailored to the needs of Philippine businesses:

MAIKONG Advantages

- Machines specifically designed for tropical climate operation

- Local technical support and service network

- Parts availability with quick shipping to the Philippines

- Energy-efficient designs to address high electricity costs

- Configurations optimized for common Philippine plastic waste streams

- Comprehensive training and operational support

- Competitive pricing with flexible financing options

MAIKONG plastic shredder installation at a Philippine recycling facility

Distributor and Agent Opportunities in the Philippines

MAIKONG is actively expanding its presence in the Philippine market through strategic partnerships with local businesses. Becoming a MAIKONG distributor offers significant advantages:

- Exclusive Territory Rights: Protected regional sales territories throughout the Philippines.

- Comprehensive Product Training: In-depth technical and sales training on the complete MAIKONG product line.

- Marketing Support: Co-branded marketing materials, technical documentation, and promotional assistance.

- Competitive Commission Structure: Attractive margins on equipment sales and ongoing parts business.

- Technical Backup: Direct access to MAIKONG engineering and support teams.

- Growing Market: Entry into the rapidly expanding plastic recycling sector in the Philippines.

Become a MAIKONG Distributor in the Philippines

Join our network of successful partners and tap into the growing demand for plastic recycling equipment in the Philippine market.

Learn About Distributor Opportunities

Conclusion

Understanding the terminology and technical aspects of plastic shredders is essential for making informed purchasing decisions. As the plastic recycling industry continues to grow in the Philippines, having the right equipment properly matched to your specific needs becomes increasingly important.

MAIKONG is committed to supporting Philippine businesses in their recycling efforts through high-quality equipment, technical expertise, and ongoing support. Whether you’re looking for a mini plastic shredder machine for a small operation or an industrial plastic shredder for large-scale recycling, our team is ready to assist you in finding the perfect solution.

Ready to Advance Your Plastic Recycling Capabilities?

Contact MAIKONG today to discuss your specific requirements and discover how our plastic shredding solutions can benefit your business in the Philippines.

Email: Lucy@plasticshredder.ph

Website: https://plasticshredder.ph