In the Philippines, where plastic waste management has become a critical environmental and economic concern, industrial-grade plastic shredders are revolutionizing recycling operations. MAIKONG, a leading manufacturer from GD, SZ, delivers cutting-edge shredding technology that transforms plastic waste into valuable recyclable materials. Our heavy-duty machines are engineered specifically for the demanding requirements of large-scale recycling facilities, manufacturing plants, and waste management operations throughout the Philippines.

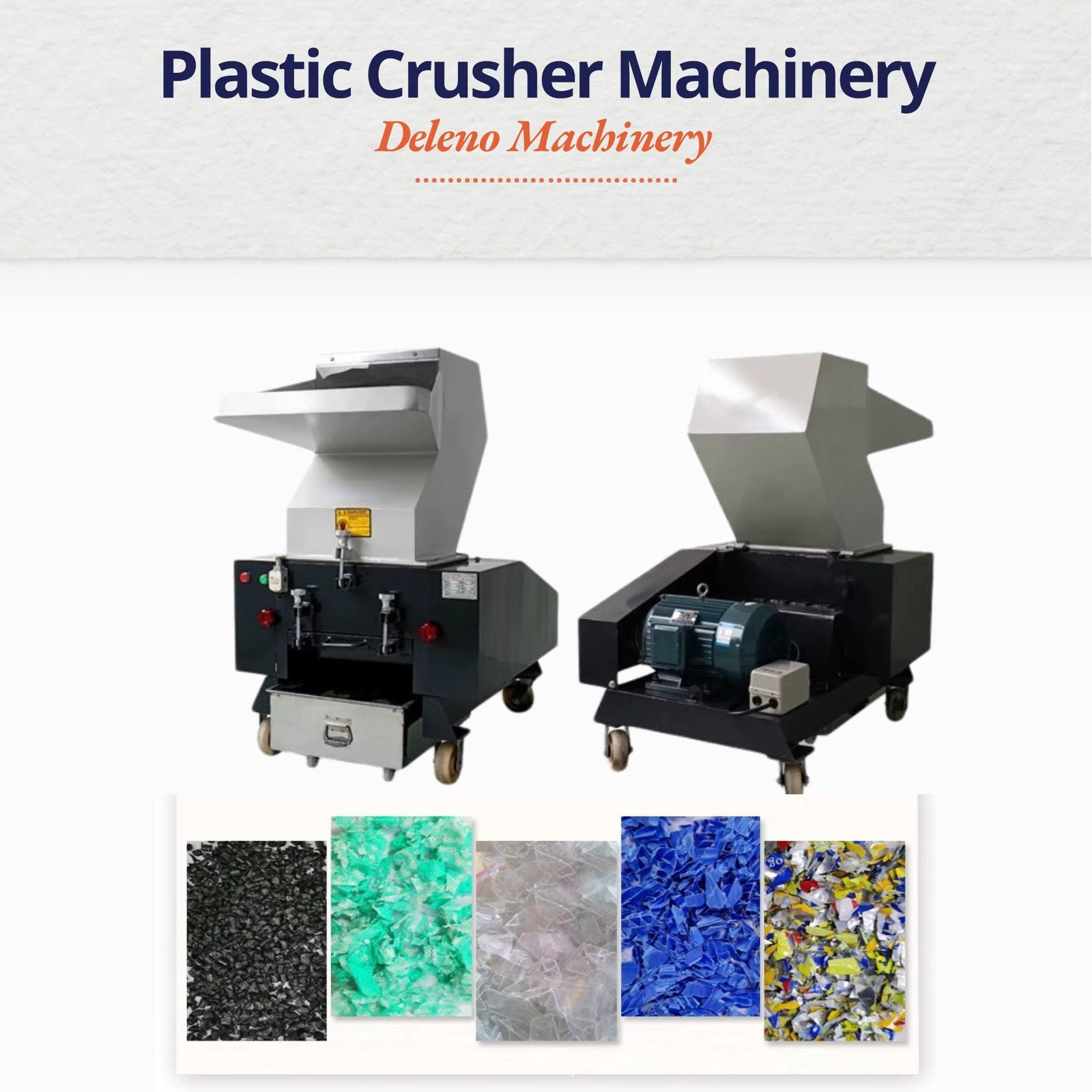

What is an Industrial Plastic Shredder Machine?

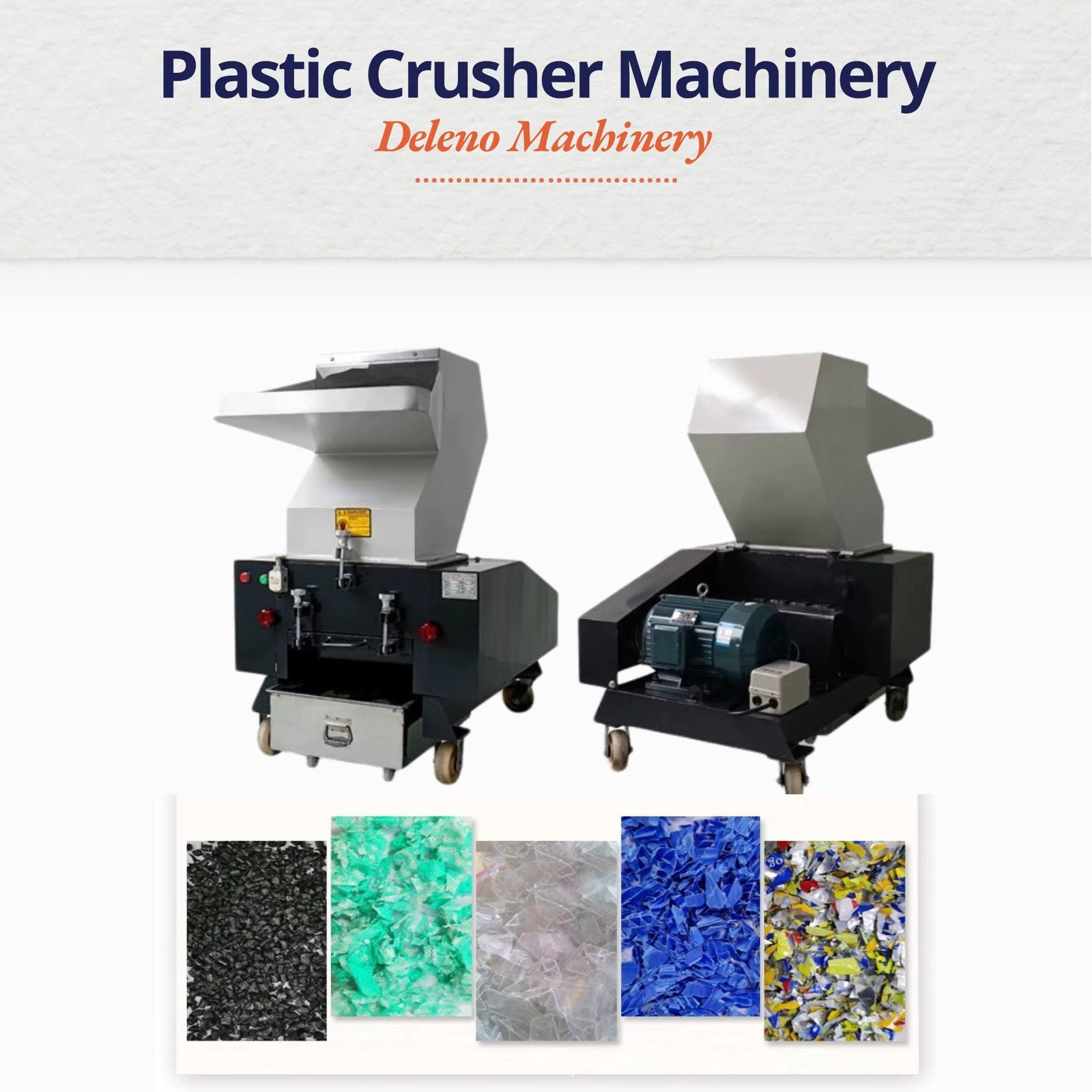

MAIKONG industrial plastic shredder processing large-volume plastic waste

An industrial plastic shredder machine is a robust piece of equipment designed to reduce the size of various plastic materials for recycling or disposal. Unlike smaller models intended for office or light commercial use, industrial shredders are engineered to handle high volumes of diverse plastic waste continuously, from rigid containers to flexible films.

The Core Function: Size Reduction for Recycling

The primary purpose of a plastic shredder is to transform bulky plastic waste into smaller, uniform pieces that are easier to process, transport, and recycle. This size reduction is a critical first step in the plastic recycling chain, preparing materials for washing, separation, and eventual reprocessing into new products.

Before and after: Plastic waste transformed by MAIKONG shredders

How Industrial Plastic Shredders Differ from Smaller Models

MAIKONG industrial plastic shredders are fundamentally different from smaller commercial or residential models in several key aspects:

Processing Power

Industrial models feature high-torque motors (ranging from 11kW to 132kW) capable of processing tons of material per hour, compared to the limited capacity of smaller units.

Durability

Built with hardened steel components and reinforced cutting chambers, these machines are designed for continuous operation in demanding environments.

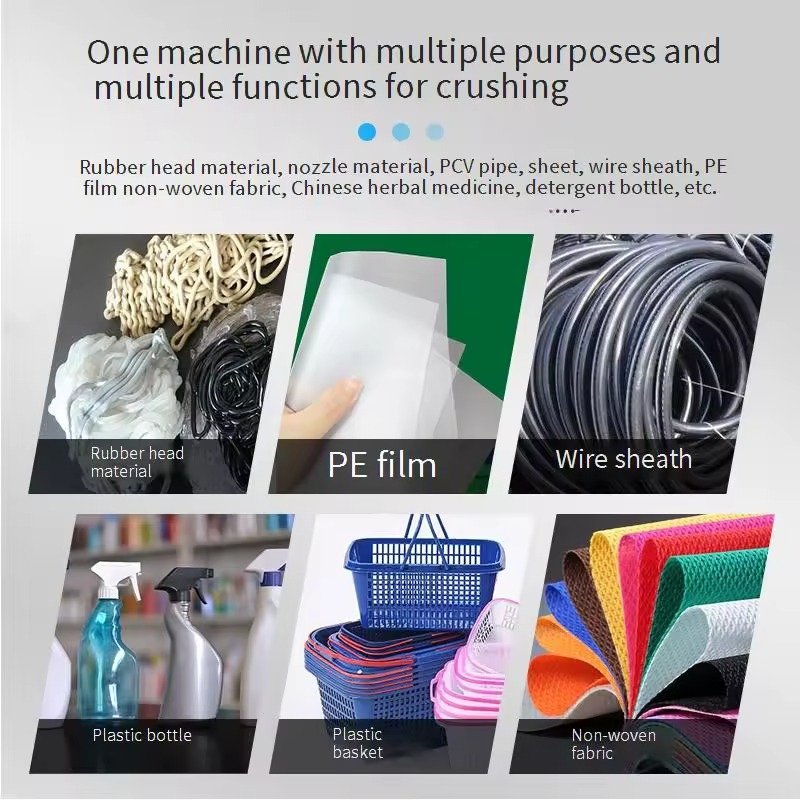

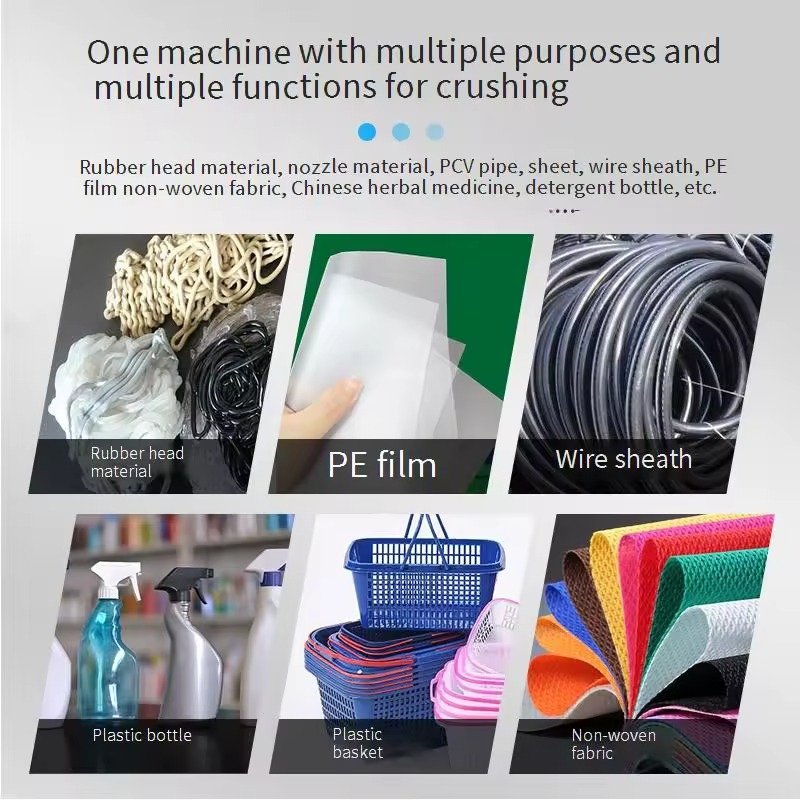

Versatility

Advanced cutting systems can handle diverse materials from rigid HDPE pipes to flexible films and fibrous materials without jamming.

Control Systems

Sophisticated PLC controls with automatic reverse functions prevent damage from foreign objects and optimize performance.

Customization

Industrial shredders offer adjustable cutting parameters, interchangeable screens, and various feeding mechanisms to match specific operational needs.

Output Quality

Precision engineering ensures consistent particle size, which is crucial for downstream recycling processes.

Key Applications of Heavy-Duty Plastic Shredders in Philippine Industries

The versatility of MAIKONG plastic shredders makes them indispensable across numerous industries in the Philippines, where plastic waste management presents unique challenges and opportunities.

Processing Post-Industrial Plastic Waste (Lumps, Purges, Runners)

MAIKONG shredder processing post-industrial plastic waste

Manufacturing facilities across the Philippines generate significant volumes of plastic waste during production. These include start-up lumps, purges, runners, and rejected parts that contain valuable resin that can be reclaimed. MAIKONG shredders efficiently process these materials, allowing manufacturers to:

- Reclaim valuable plastic materials that would otherwise be discarded

- Reduce raw material costs by reintroducing recycled content

- Minimize waste disposal expenses

- Create closed-loop manufacturing systems

- Meet sustainability goals and regulatory requirements

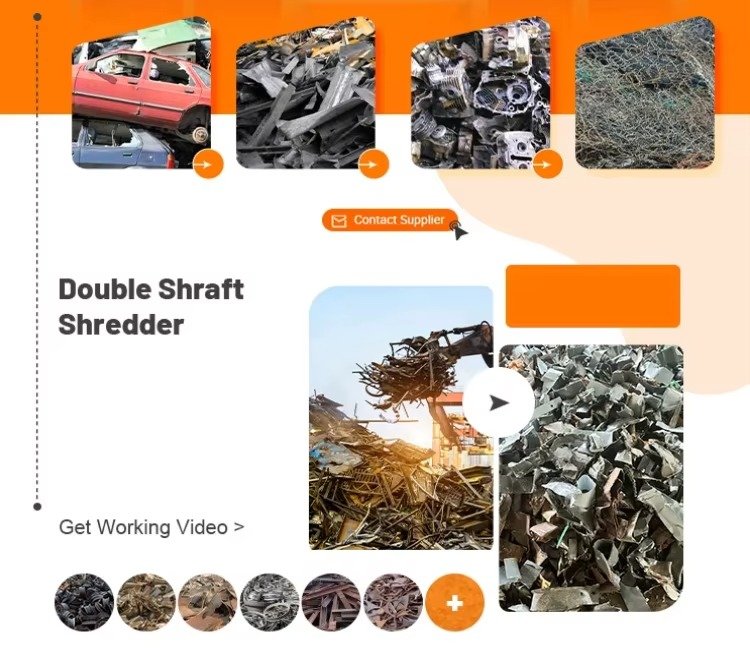

Large-Scale Post-Consumer Plastic Recycling

Post-consumer plastic recycling with MAIKONG industrial shredders

The Philippines faces significant challenges with post-consumer plastic waste management. MAIKONG shredders play a vital role in processing diverse consumer plastics including:

| Plastic Type |

Common Sources |

Recycling Challenge |

MAIKONG Solution |

| PET (Type 1) |

Beverage bottles, food containers |

High volume, contamination |

High-throughput shredding with washing preparation |

| HDPE (Type 2) |

Milk jugs, detergent bottles, pipes |

Thick-walled, rigid materials |

High-torque cutting system with specialized blades |

| PVC (Type 3) |

Construction pipes, vinyl products |

Abrasive, hard on equipment |

Hardened cutters with wear-resistant design |

| LDPE (Type 4) |

Plastic bags, films, packaging |

Tends to wrap around cutters |

Anti-wrapping rotor design with specialized film cutters |

| PP (Type 5) |

Food containers, bottle caps |

Mixed with other materials |

Precise cutting for downstream separation |

| PS (Type 6) |

Foam packaging, disposable cutlery |

Low density, high volume |

Specialized feeding systems for light materials |

Specialized Shredding: Pipes, Bottles, Containers, and More

Specialized plastic waste processing with MAIKONG technology

Beyond general plastic recycling, MAIKONG shredders excel at processing challenging materials that require specialized handling:

HDPE Pipes

Our reinforced cutting systems easily process thick-walled pipes from construction and plumbing industries, reducing them to uniform particles ideal for reprocessing.

IBC Containers

Large industrial containers are efficiently reduced in size, separating plastic components from metal frames for comprehensive recycling.

Agricultural Films

Specialized rotors handle thin, flexible agricultural films without wrapping or jamming, preparing them for washing and pelletizing.

Need a specialized solution for your plastic waste?

Our engineers can customize a shredding system for your specific materials and throughput requirements.

Request a Consultation

Inside a MAIKONG Industrial Plastic Shredder: Key Components and Technology

Cutaway view of MAIKONG industrial plastic shredder technology

The exceptional performance of MAIKONG industrial plastic shredders stems from their advanced engineering and premium components. Understanding these key elements helps appreciate the value and capabilities these machines bring to recycling operations.

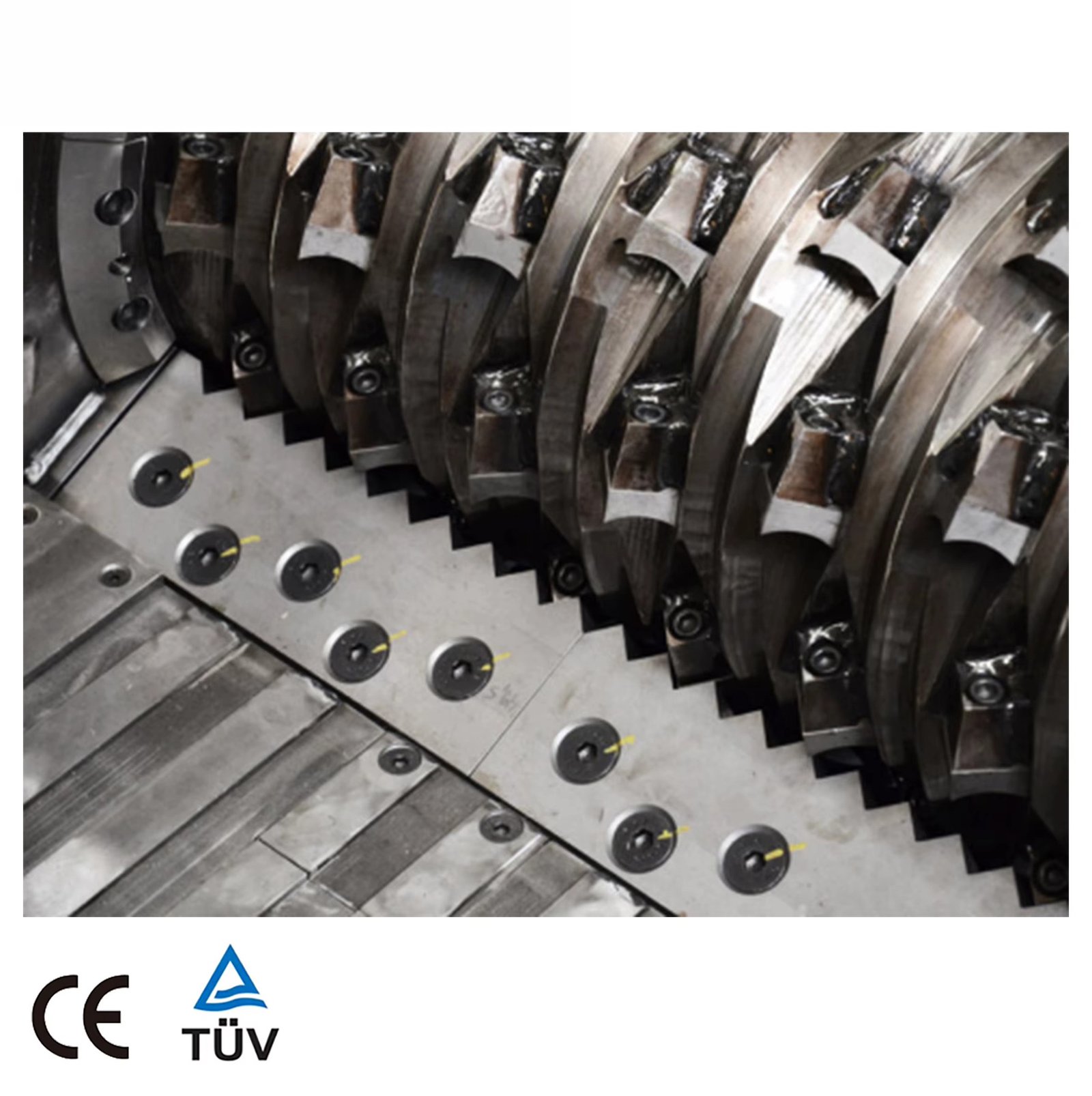

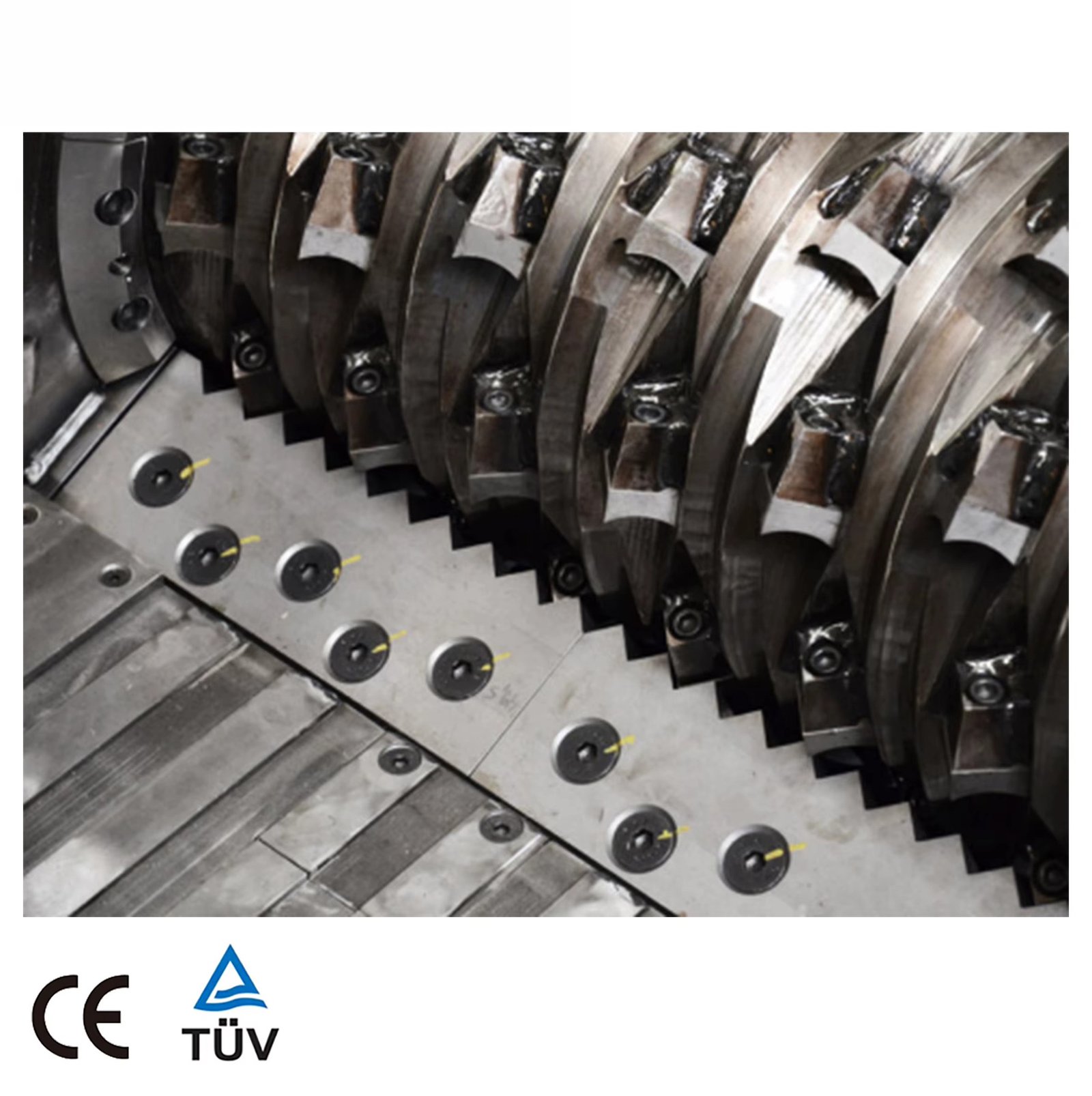

Robust Rotor Designs for Maximum Durability

MAIKONG’s precision-engineered rotor assembly with hardened cutting blades

At the heart of every MAIKONG shredder is a precision-engineered rotor system designed for optimal cutting performance and longevity:

- Solid steel construction machined from high-grade alloys

- Balanced design for smooth operation and reduced vibration

- Multiple rotor configurations available for different material types

- Specialized designs for films, rigid plastics, or mixed materials

- Optimized cutting geometry for maximum efficiency

High-Strength Plastic Shredder Parts and Blades

MAIKONG high-strength replacement blades and critical components

The cutting system is engineered for performance in demanding applications:

Blade Technology

Our blades are manufactured from specially formulated tool steel with precise heat treatment for optimal hardness and wear resistance. Each blade undergoes rigorous quality control to ensure consistent performance.

Mounting Systems

Innovative blade mounting designs allow for quick replacement and rotation, maximizing usable cutting edges and reducing maintenance downtime.

Customized Geometries

Different blade profiles are available for specific materials, from aggressive designs for rigid plastics to specialized shapes for films and fibers.

Wear Components

All wear surfaces feature replaceable liners and reinforced construction to protect the machine’s structural integrity during operation.

MAIKONG maintains comprehensive inventories of plastic shredder parts to support our customers throughout the Philippines, ensuring minimal downtime for maintenance and repairs.

Power Systems: Electric vs. Hydraulic Motors

MAIKONG offers both electric and hydraulic drive systems for different applications

MAIKONG offers multiple drive system options to match specific operational requirements:

Electric Drive Systems

- Direct efficiency with lower operating costs

- Power options from 11kW to 132kW

- Ideal for consistent materials and continuous operation

- Lower maintenance requirements

- Quieter operation for indoor facilities

Hydraulic Drive Systems

- Superior torque for challenging materials

- Automatic overload protection

- Variable speed control for different materials

- Better handling of shock loads and foreign objects

- Ideal for inconsistent waste streams

Advanced Control Systems with PLC

Advanced PLC control system on MAIKONG industrial plastic shredder

Modern MAIKONG shredders feature sophisticated control systems that optimize performance and protect the equipment:

- Programmable Logic Controllers (PLC) for precise operational control

- Automatic load sensing with adaptive power management

- Foreign object detection with automatic reversing

- User-friendly interface with operational statistics

- Remote monitoring capabilities for preventive maintenance

- Customizable operating parameters for different materials

Benefits of Investing in a MAIKONG Industrial Plastic Shredder

Modern recycling facility powered by MAIKONG shredding technology

Investing in a MAIKONG industrial plastic shredder delivers substantial benefits for recycling operations in the Philippines, creating both immediate and long-term value.

Dramatic Waste Volume Reduction and Cost Savings

MAIKONG shredders can reduce waste volume by up to 80%

One of the most immediate benefits is the significant reduction in waste volume:

- Reduce storage space requirements by up to 80%

- Lower transportation costs through increased load density

- Reduce disposal fees based on volume

- Minimize handling costs with more efficient material flow

- Optimize container utilization for shipping recycled materials

4.8

Average Customer Satisfaction

Operational Efficiency

4.5/5

Creating High-Quality Regrind for Reuse

Uniform, high-quality plastic regrind produced by MAIKONG shredders

MAIKONG shredders produce consistent, high-quality output that maximizes material value:

- Uniform particle size for efficient downstream processing

- Clean cuts that minimize dust and fines

- Consistent output that meets specifications for reprocessing

- Higher market value for processed materials

- Direct reuse potential in manufacturing processes

Enhancing Operational Efficiency and Sustainability Goals

Streamlined recycling operations with MAIKONG shredding technology

Beyond direct cost savings, MAIKONG shredders deliver broader operational benefits:

Operational Advantages

- Increased throughput capacity

- Reduced labor requirements

- Lower energy consumption per ton processed

- Simplified material handling

- Enhanced workplace safety

- Reduced environmental impact

Without Proper Shredding

- Excessive storage space required

- Higher transportation costs

- Increased disposal fees

- Limited recycling options

- Inefficient material handling

- Greater environmental footprint

Ready to transform your plastic waste into value?

Contact our team to discuss how MAIKONG shredders can improve your recycling operations.

Contact via WhatsApp

Choosing the Right Model: MAIKONG’s Heavy-Duty Plastic Shredder Range

MAIKONG offers a comprehensive range of plastic shredders for every application

MAIKONG offers a comprehensive range of plastic shredder models to address the diverse needs of recycling operations in the Philippines. Our product line includes:

Model Comparison and Specifications

| Model |

Blade Diameter |

Motor Power |

Throughput |

Ideal Applications |

| MAIKONG-600 |

220mm |

11kW-15kW (dual) |

300-500 kg/hr |

Small recycling operations, in-plant recycling |

| MAIKONG-800 |

300mm |

18.5kW-22kW (dual) |

500-800 kg/hr |

Medium recycling facilities, plastic manufacturing |

| MAIKONG-1000 |

400mm |

45kW (dual) |

800-1200 kg/hr |

Large recycling operations, post-consumer waste |

| MAIKONG-1400 |

500mm |

55kW (dual) |

1200-1800 kg/hr |

Industrial recycling, high-volume processing |

| MAIKONG-1800 |

600mm |

90kW (dual) |

1800-2500 kg/hr |

Large-scale recycling plants, challenging materials |

| MAIKONG-2000 |

650mm |

132kW (dual) |

2500+ kg/hr |

Maximum capacity operations, industrial-scale recycling |

For smaller operations or specialized applications, we also offer mini plastic shredder machines and small plastic shredders that deliver the same MAIKONG quality in more compact formats.

Customization Options: Conveyors, Cyclones, Pushers, etc.

Customized MAIKONG shredding system with integrated conveyor and collection systems

MAIKONG shredders can be tailored to specific operational requirements with a wide range of customization options:

Feeding Systems

- Inclined belt conveyors

- Vibrating feeders

- Hydraulic bin tippers

- Manual loading hoppers

Force-Feed Mechanisms

- Hydraulic ram pushers

- Pneumatic assist systems

- Gravity feed enhancements

- Specialized film feeders

Discharge Options

- Collection conveyors

- Pneumatic transport systems

- Cyclone separators

- Bagging stations

Our engineering team works closely with customers to design complete systems that integrate seamlessly with existing operations or new recycling lines.

MAIKONG’s Commitment to the Philippine Market

MAIKONG provides comprehensive local support throughout the Philippines

MAIKONG is committed to supporting our Philippine customers with comprehensive service and support that ensures maximum equipment performance and longevity.

Local Support and Distributors Network

We maintain a strong presence in the Philippines through our network of authorized distributors and service partners:

- Local technical expertise for prompt support

- Strategically located service centers throughout the country

- Factory-trained technicians familiar with local conditions

- Regular training and certification programs

- Demonstration facilities for hands-on equipment evaluation

Comprehensive After-Sales Service and Plastic Shredder Parts Supply

MAIKONG maintains comprehensive parts inventories for rapid support

Our commitment extends beyond the initial equipment sale to ensure ongoing operational success:

Maintenance Programs

Scheduled preventive maintenance plans tailored to your specific equipment and operating conditions, maximizing uptime and performance.

Parts Availability

Comprehensive inventory of genuine plastic shredder parts with fast delivery throughout the Philippines.

Technical Support

Remote diagnostics and troubleshooting assistance from factory-trained technicians, available via phone, email, or video call.

Operator Training

Comprehensive training programs for machine operators and maintenance personnel to ensure safe and efficient equipment operation.

Getting Started with Your Large-Scale Recycling Project

MAIKONG experts provide comprehensive consultation for recycling projects

Implementing a large-scale plastic recycling solution requires careful planning and expert guidance. MAIKONG’s team is ready to support your project from initial concept through implementation and beyond.

Contact MAIKONG Experts for a Consultation

Our experienced team can help you determine the optimal shredding solution for your specific requirements:

- Assessment of your material stream and processing requirements

- Throughput analysis and equipment sizing recommendations

- Integration planning with existing systems or new recycling lines

- ROI calculations and operational cost projections

- Implementation timeline and logistics planning

Prefer to speak directly with our team?

Contact us via phone, WhatsApp, or email for immediate assistance.

Transform Your Plastic Waste Management with MAIKONG Plastic Shredders

Complete MAIKONG plastic recycling solutions in action

As the Philippines continues to address the challenges of plastic waste management, MAIKONG stands ready as your trusted partner in implementing effective, efficient recycling solutions. Our heavy-duty plastic shredders combine robust engineering, advanced technology, and comprehensive support to deliver exceptional value for recycling operations of all sizes.

Whether you’re establishing a new recycling facility, upgrading existing equipment, or expanding your processing capabilities, MAIKONG offers the expertise, technology, and support you need to succeed. Contact our team today to discover how our industrial plastic shredder solutions can transform your operation, reduce costs, and contribute to a more sustainable future for the Philippines.

Ready to take the next step?

Visit our website to explore our complete range of plastic recycling solutions.

Visit MAIKONG Website