Transform your plastic recycling operation with MAIKONG’s advanced Integrated Shredder-Granulator Systems. Our all-in-one solutions combine powerful shredding and precise granulation in a single compact unit, eliminating the need for separate machines and intermediate conveying systems. Designed specifically for the Philippine market, these systems help recycling facilities and manufacturing plants maximize efficiency while minimizing floor space and operational costs.

Ready to Revolutionize Your Recycling Process?

Contact our specialists today for a personalized consultation and quote tailored to your specific material processing needs.

Request a Quote Call: 008613-51090-74-01

What is an Integrated Shredder-Granulator System?

An Integrated Shredder-Granulator System represents a significant advancement in plastic recycling technology, combining two essential processing stages into a single, unified machine. Unlike traditional setups that require separate shredders and granulators connected by conveyor systems, these integrated units perform both operations sequentially within one compact footprint.

The Two-Stage Process in One Machine

The system operates through a precisely engineered sequential process:

- The upper shredding section uses low-speed, high-torque cutting action to reduce large plastic items into manageable pieces

- These pre-shredded materials automatically fall into the lower granulation chamber

- The high-speed granulator further processes the material into uniform granules of specified size

- Final particles pass through a screen system that ensures consistent output size

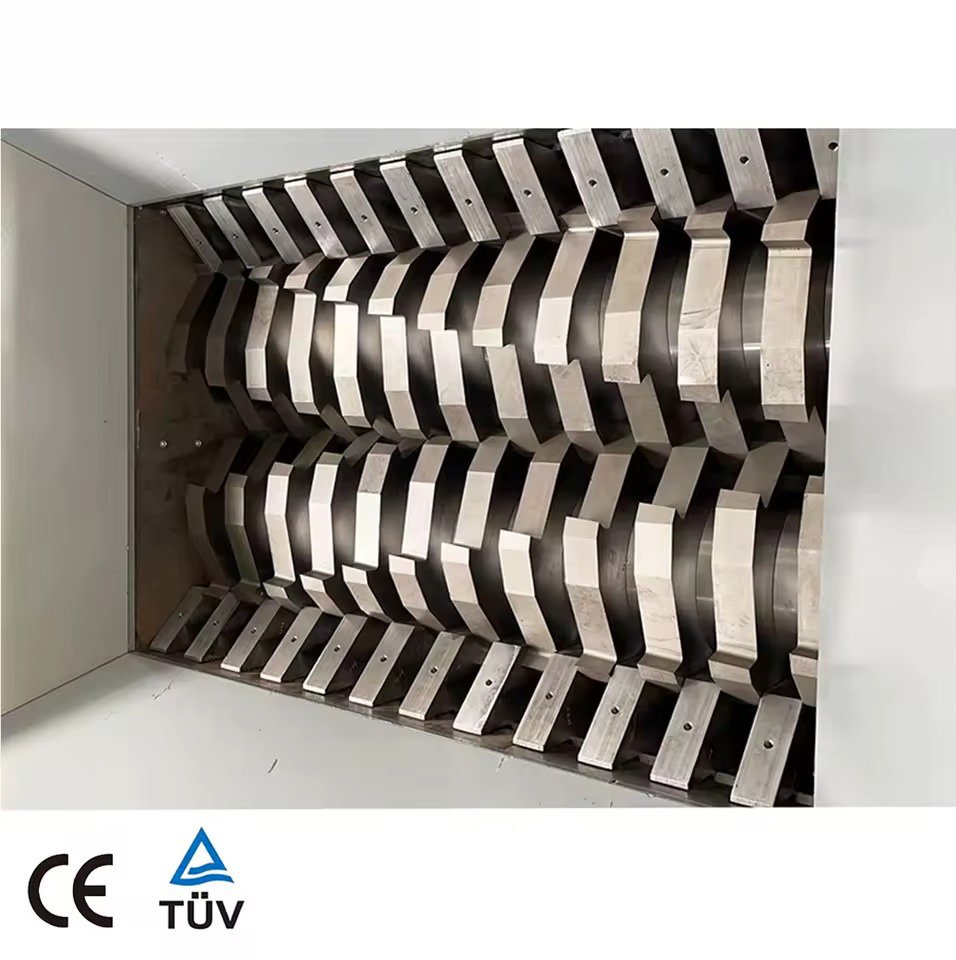

MAIKONG’s Integrated Shredder-Granulator System with dual-stage processing technology

Key Advantages of Integrated Systems Over Separate Units

Space Optimization

Reduce your equipment footprint by up to 50% compared to separate machines. This space-saving design is particularly valuable for facilities in the Philippines where production floor space comes at a premium.

Cost Efficiency

Eliminate the need for intermediate conveying equipment, reducing both initial investment and ongoing maintenance costs. Our integrated design also lowers energy consumption by optimizing the material flow between processes.

Operational Simplicity

Manage your entire size reduction process through a single control interface. Our PLC-based system automates the coordination between shredding and granulation stages, reducing the need for operator intervention and specialized training.

Advantages of Integrated Systems

- Single-step processing eliminates material handling between stages

- Reduced energy consumption (25% average savings)

- Lower maintenance requirements with fewer moving parts

- Consistent output quality through coordinated processing

- Smaller footprint saves valuable production space

- Simplified operation with unified control system

Limitations of Separate Systems

- Requires additional conveying equipment between machines

- Higher energy consumption from multiple motors

- More complex maintenance schedule

- Greater floor space requirements

- Material loss during transfer between machines

- Multiple control systems to manage

How Plastic Lumps & Waste Are Generated

Understanding the sources of plastic waste in manufacturing processes helps identify the ideal applications for integrated shredder-granulator systems. In the Philippines’ growing manufacturing sector, these waste streams represent significant recycling opportunities.

Injection Molding Waste

- Runners and sprues from the molding process

- Purging material during color or material changes

- Rejected parts that don’t meet quality standards

- Start-up waste during machine calibration

Blow Molding Waste

- Flash and trimmings from the blow process

- Rejected bottles and containers

- Purge material during transitions

- Thickness variations causing quality issues

Thermoforming Waste

- Skeletal waste after part removal

- Edge trimmings from sheet processing

- Rejected formed parts

- Start-up and changeover waste

Did you know? According to industry estimates, manufacturing waste can account for 15-25% of total plastic material usage in production processes. Reclaiming this material through efficient recycling can significantly reduce raw material costs and environmental impact.

Types of Plastic Waste Suitable for Integrated Systems

MAIKONG’s Integrated Shredder-Granulator Systems are designed to process a wide range of plastic materials commonly used in Philippine manufacturing and packaging industries.

| Plastic Type |

Common Forms |

Processing Characteristics |

Recycling Value |

| #2 HDPE |

Bottles, containers, crates, bins, pallets, pipes |

Medium hardness, good flow properties |

High |

| #4 LDPE/LLDPE |

Film, bags, containers, rotomolded parts |

Flexible, may require anti-wrapping rotor |

Medium |

| #5 PP |

Containers, caps, crates, automotive parts |

Good rigidity, processes well |

Medium-High |

| #3 PVC |

Pipes, profiles, window frames, siding |

Harder material, requires robust cutting system |

Medium |

| #1 PET |

Bottles, containers, thermoformed packaging |

Abrasive when processed, may require special blades |

High |

Not Sure Which System Fits Your Material Needs?

Our technical team can analyze your specific waste stream and recommend the optimal configuration.

Email Our Experts

Core Components & Technology of MAIKONG Integrated Systems

The Shredding Module

The upper shredding section features our advanced cutting technology designed for efficient primary size reduction:

- Rotor Design: Available in universal (for hard materials) and anti-tangle (for films/flexible materials) configurations

- Blade Technology: High-grade D2/SKD11 alloy steel blades with precision cutting geometry

- Drive System: Low-speed, high-torque operation with overload protection

- Cutting Chamber: Reinforced steel construction with wear-resistant liners

The Granulating Module

The lower granulation section delivers precise final sizing with our patented cutting technology:

- Rotor Configuration: Open design with 3-blade arrangement in scissor-cut pattern

- Screen System: Interchangeable screens (4-30mm) for precise particle size control

- Cutting Action: Double V-arrangement technology for clean, efficient cuts

- Bearing System: Heavy-duty bearings with specialized sealing against contamination

Conveyance & Automation

Our integrated systems feature advanced material handling and control technologies:

Infeed Systems

- Hydraulic ram feeders for bulky materials

- Hopper designs optimized for different material types

- Optional conveyor feeding for continuous operation

Control Systems

- PLC-based operation with touchscreen interface

- Automatic load sensing and feed rate optimization

- Integrated safety monitoring and shutdown protocols

Output Collection

- Integrated blower systems for pneumatic conveying

- Cyclone separators for dust-free collection

- Options for direct bagging or container filling

MAIKONG’s advanced PLC control system with intuitive touchscreen interface

Applications in the Philippine Context

MAIKONG’s Integrated Shredder-Granulator Systems are ideally suited for the diverse recycling needs of the Philippine market, addressing specific challenges faced by local industries.

Manufacturing Facilities

Ideal for in-house recycling of production scrap in plastic manufacturing operations. Enables immediate reprocessing of runners, rejects, and purge material, reducing raw material costs.

View Industrial Solutions

Recycling Businesses

Perfect for commercial recyclers processing post-consumer and post-industrial plastic waste. The compact design maximizes processing capacity in limited space, a common challenge in Philippine facilities.

Explore Recycling Equipment

Small-Scale Operations

Scaled solutions for smaller operations and start-ups in the growing Philippine recycling sector. Provides professional-grade processing capability with minimal space and power requirements.

See Small-Scale Options

Local Success Story: A manufacturing facility in Manila reduced their plastic waste disposal costs by 85% and raw material purchases by 20% after implementing a MAIKONG Integrated Shredder-Granulator System. The compact design allowed installation directly beside their production line, eliminating material transport and storage requirements.

Choosing the Right System: MAIKONG’s Product Range

MAIKONG offers a comprehensive range of Integrated Shredder-Granulator Systems designed to meet diverse processing requirements and material challenges.

| Model |

Processing Capacity |

Motor Power |

Ideal Applications |

Key Features |

| MK-SG300 |

200-300 kg/hr |

30kW + 22kW |

Small manufacturing operations, start-up recyclers |

Compact footprint, single-phase power option, mobile base |

| MK-SG500 |

400-600 kg/hr |

45kW + 30kW |

Medium-sized recycling operations, production facilities |

Balanced performance/size ratio, versatile material handling |

| MK-SG800 |

700-900 kg/hr |

75kW + 45kW |

Large recycling centers, high-volume manufacturing |

Heavy-duty construction, advanced automation, high throughput |

Customization Options

MAIKONG systems can be tailored to your specific requirements:

- Rotor Configurations: Specialized designs for different material types

- Screen Sizes: Customizable from 4mm to 30mm for precise output control

- Feeding Systems: Options for manual, conveyor, or hydraulic feeding

- Control Systems: Basic to advanced automation with remote monitoring

- Material Handling: Integrated collection and packaging solutions

MAIKONG’s technical team customizing a system for specific customer requirements

Find Your Perfect System

Browse our complete range of integrated solutions and supporting equipment.

Frequently Asked Questions

What is the main advantage of an integrated system over separate machines?

The primary benefits include significant space savings (up to 50%), elimination of intermediate conveying equipment, reduced energy consumption, simplified maintenance, and a more streamlined operation with a single control system. For Philippine facilities where space is often at a premium, the compact design provides substantial advantages.

What types of plastic materials can these systems process?

MAIKONG Integrated Shredder-Granulator Systems can process a wide range of plastics including HDPE, LDPE, PP, PVC, PET, and mixed plastics. They are particularly effective for bulky items that standard granulators cannot handle directly, such as large containers, thick sheets, purge lumps, and production rejects.

How is the final particle size controlled?

The final output size is determined by the screen installed in the granulator section. MAIKONG systems come with standard screen sizes ranging from 4mm to 30mm, with custom sizes available to meet specific requirements. The screen ensures that material cannot exit the processing chamber until it reaches the desired size.

What safety features are included in MAIKONG systems?

Our systems incorporate comprehensive safety features including emergency stop buttons, safety interlocks on access doors, automatic overload protection with reverse function, current monitoring, and thermal protection for motors. All systems comply with international safety standards to ensure operator protection and equipment longevity.

What support and maintenance services does MAIKONG provide in the Philippines?

MAIKONG offers complete support services including installation, operator training, preventive maintenance programs, and rapid response technical support. We maintain a stock of critical spare parts for quick delivery throughout the Philippines, and our local technical team provides both remote and on-site assistance when needed.

Transform Your Plastic Recycling Operation Today

MAIKONG’s Integrated Shredder-Granulator Systems represent the future of efficient plastic recycling. By combining powerful shredding and precise granulation in a single compact unit, these systems help Philippine businesses maximize productivity while minimizing costs and space requirements.

Whether you’re a manufacturing facility looking to reclaim production waste, a recycling operation processing post-consumer materials, or a start-up entering the recycling industry, MAIKONG offers the perfect integrated solution for your specific needs.

Ready to Optimize Your Recycling Process?

Contact our experts today to discuss your requirements and discover the ideal integrated system for your operation.

Learn more about MAIKONG and our commitment to quality recycling solutions.