In today’s industrial environments, noise pollution is a significant concern for plastic processing facilities. Low speed high torque shredders offer a revolutionary solution that drastically reduces operational noise while maintaining exceptional performance. These specialized machines operate on a fundamentally different principle than conventional high-speed shredders, providing Philippine businesses with quieter, more efficient plastic recycling operations. MAIKONG’s advanced shredder technology combines powerful torque with reduced operational speeds to create a superior shredding experience that prioritizes both performance and workplace comfort.

How Low Speed High Torque Shredders Work

Understanding the fundamental operating principles behind low speed high torque shredders helps explain their exceptional noise reduction capabilities. Unlike conventional high-speed shredders that rely on impact and velocity, these machines utilize powerful rotational force at significantly lower speeds.

MAIKONG’s low speed high torque shredder cutting mechanism

Core Operating Components

The exceptional performance of low speed high torque shredders comes from several key components working in harmony:

Power Transmission System

MAIKONG shredders utilize high-power electric motors paired with specialized gearboxes that convert high-speed, low-torque output into low-speed, high-torque power. This transformation is the foundation of their quiet operation. Some models feature hydraulic motor drives for even greater torque and superior overload protection.

Cutting Mechanism

Rather than sharp blades, these shredders employ specially designed cutters resembling hooks or square teeth. Mounted on counter-rotating shafts, these cutters operate at just 20-60 RPM, dramatically reducing operational noise while maintaining exceptional shredding capability.

Shearing and Tearing Process

The noise reduction advantage comes directly from the shredding method:

- Material enters through the feed port where rotating cutters “hook” and “grab” it

- The counter-rotating shafts pull material through a narrow gap between them

- High torque exerts tremendous shearing force, tearing materials apart rather than impacting them

- This controlled tearing process generates significantly less noise than high-speed impact shredding

- A screen with specific-sized holes ensures uniform output size

Experience Quieter Plastic Processing

Discover how MAIKONG’s low speed high torque technology can transform your operation with reduced noise levels.

Request Information

Noise Reduction Benefits for Philippine Businesses

The exceptional noise reduction capabilities of low speed high torque shredders provide numerous advantages for plastic processing facilities in the Philippines.

Noise level comparison: Traditional vs. MAIKONG low speed high torque shredders

Advantages of Low Noise Operation

- Improved workplace safety and reduced hearing damage risk

- Enhanced communication between operators

- Decreased operator fatigue and stress

- Easier compliance with Philippine noise regulations

- Ability to operate in noise-sensitive areas

- Reduced need for expensive soundproofing

- Better community relations with neighboring businesses

Challenges of High-Speed Shredders

- Excessive noise requiring hearing protection

- Increased workplace stress and fatigue

- Potential regulatory compliance issues

- Communication difficulties between operators

- Higher costs for noise mitigation measures

- Complaints from neighboring businesses

- Limited operational hours in some locations

Measurable Noise Reduction

MAIKONG’s low speed high torque shredders typically operate at 65-75 decibels compared to 85-95 decibels for conventional high-speed models. This 10-20 decibel reduction represents a significant decrease in perceived noise levels, creating a dramatically improved working environment.

“The switch to MAIKONG’s low speed high torque shredder reduced our facility noise levels so dramatically that we no longer require hearing protection in the processing area. This has improved worker communication and overall satisfaction.”

– Plastic Recycling Facility Manager, Manila

Comparing Low Speed vs. High Speed Shredders

Understanding the key differences between low speed high torque shredders and conventional high-speed models helps illustrate why the former excels at noise reduction.

| Feature |

Low Speed High Torque Shredders |

High Speed Shredders |

| Operating Speed |

20-60 RPM |

500-3000 RPM |

| Noise Level |

65-75 dB |

85-95 dB |

| Working Principle |

Shearing and tearing |

Impact and grinding |

| Energy Efficiency |

High – energy directed to material processing |

Lower – energy lost as heat and noise |

| Dust Generation |

Minimal |

Significant |

| Heat Production |

Low |

High |

| Maintenance Requirements |

Lower – less wear on components |

Higher – increased component stress |

Why Low Speed Equals Lower Noise

The physics behind noise reduction in low speed high torque shredders is straightforward:

- Reduced impact velocity means less kinetic energy converted to sound

- Slower blade rotation creates fewer air disturbances

- Controlled material processing generates less chaotic movement

- Lower operational speeds reduce mechanical vibration

- Shearing action produces less abrupt material fracturing

MAIKONG’s low speed high torque shredder in operation – note the absence of hearing protection

Contact via WhatsApp

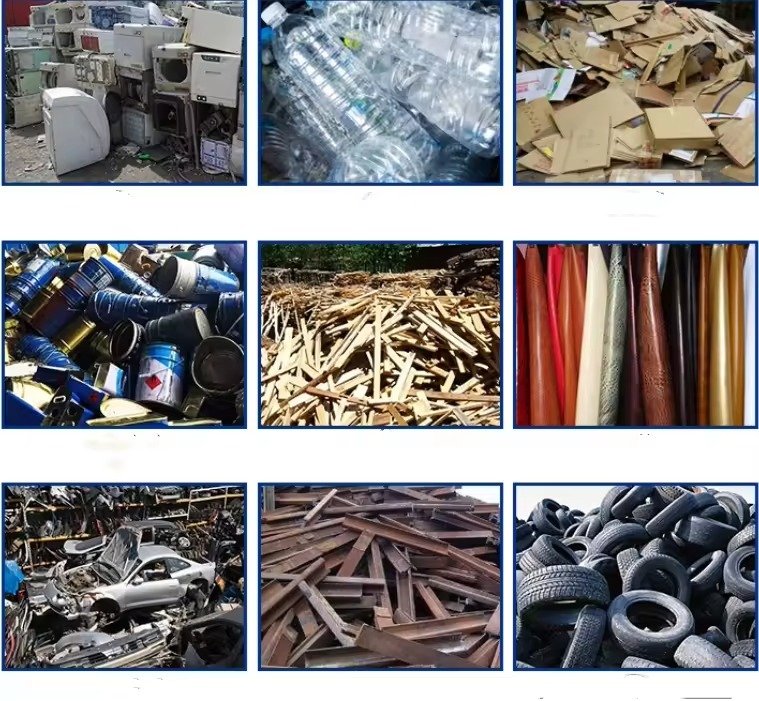

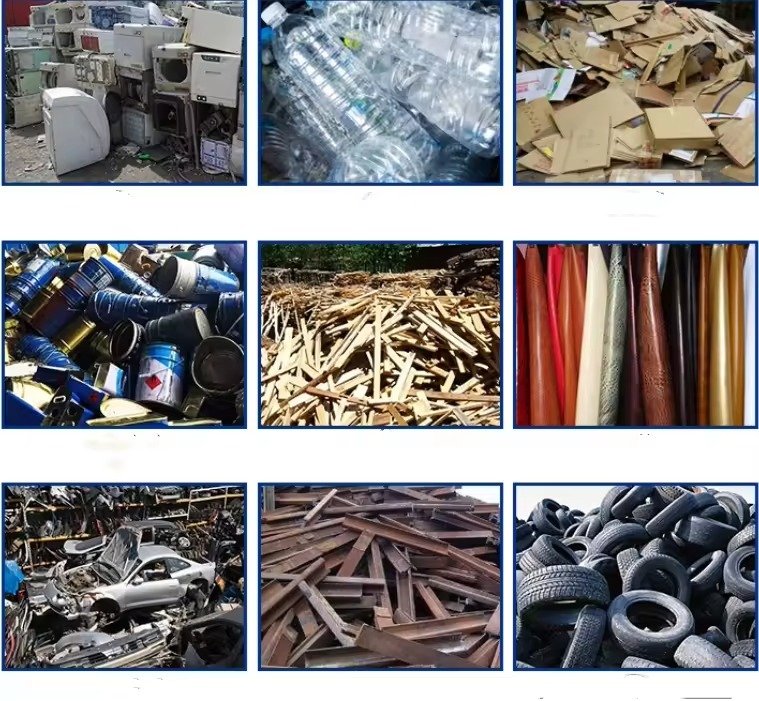

Applications for Various Plastic Materials

MAIKONG’s low speed high torque shredders excel at processing a wide range of plastic materials while maintaining their noise reduction benefits.

HDPE Processing

Effectively shreds plastic totes, trays, crates, bins, bottles, baskets, jugs, storage containers, pails, buckets, and more with minimal noise generation.

Learn More

LDPE & LLDPE Processing

Quietly processes plastic film, cups, lids, bins, containers, rotomolded parts, playground equipment, and linear materials.

Learn More

PVC Processing

Handles “vinyl” window trim, fencing, siding, purge, and pipe with significantly reduced operational noise compared to high-speed alternatives.

Learn More

Specialized Applications

The noise reduction benefits of low speed high torque shredders make them particularly valuable for specific applications:

Indoor Processing Facilities

For operations located in shared buildings or urban areas, the reduced noise levels allow for processing without disturbing neighboring businesses or requiring extensive soundproofing investments.

Extended Operating Hours

The quieter operation enables facilities to extend processing hours into evenings or early mornings without violating noise ordinances, increasing overall productivity and equipment utilization.

Find the Perfect Shredder for Your Application

MAIKONG offers customized low speed high torque shredders optimized for your specific plastic materials.

Request Custom Solution

Technical Features of MAIKONG Low Speed High Torque Shredders

MAIKONG’s low speed high torque shredders incorporate advanced technical features that enhance their noise reduction capabilities while ensuring exceptional performance.

Key components of MAIKONG’s low speed high torque shredder technology

Advanced Drive Systems

Our shredders feature:

- High-efficiency electric motors with optimized power curves

- Precision-engineered gearboxes that maximize torque while minimizing operational noise

- Optional hydraulic drive systems for maximum torque and overload protection

- Vibration-dampening mounts that prevent noise transmission to the facility structure

- Variable frequency drives for precise speed control and noise optimization

Cutting Technology

The heart of MAIKONG’s noise reduction advantage lies in our cutting system:

Specialized Blade Design

Our shredders utilize specially designed blades made from high-alloy steel. Rather than sharp cutting edges, these blades feature hook or claw-like profiles that grip and tear materials with minimal impact noise. The staggered arrangement ensures continuous material engagement without the sharp impacts common in high-speed systems.

Customizable Configurations

MAIKONG offers multiple blade configurations optimized for different materials. From our standard rotor for general-purpose applications to specialized designs for flexible films or extremely hard materials, each configuration maintains the noise reduction benefits while maximizing processing efficiency.

Intelligent Control Systems

Advanced electronic controls enhance both performance and noise reduction:

- PLC control systems that monitor operational parameters in real-time

- Automatic overload protection with reverse functionality

- Optimized start-up sequences that minimize initial noise spikes

- Energy management systems that maintain ideal torque-to-speed ratios

- Remote monitoring capabilities for performance optimization

MAIKONG Low Speed High Torque Shredder Models

MAIKONG offers a comprehensive range of low speed high torque shredders to meet diverse processing requirements while maintaining exceptional noise reduction performance.

| Model |

Blade Diameter |

Motor Power |

Dimensions (L×W×H mm) |

Ideal Application |

| MK-600 |

220mm |

11kW×2-15kW×2 |

2500×1100×1600 |

Small-scale plastic recycling |

| MK-800 |

300mm |

18.5kW×2-22kW×2 |

3000×1400×1800 |

Medium capacity processing |

| MK-1000 |

400mm |

45kW×2 |

3900×1800×2200 |

Industrial plastic recycling |

| MK-1200 |

400mm |

45kW×2 |

4100×1800×2300 |

High-volume processing |

| MK-1600 |

500mm |

75kW×2 |

5400×2400×2600 |

Large industrial applications |

Customization Options

MAIKONG offers extensive customization to optimize noise reduction and performance:

Infeed Systems

Automatic material infeed via belt conveyor or screw conveyor with inclined chutes for forklift or crane loading, designed for smooth operation and minimal noise.

Output Collection

Choose from cyclone collection systems, belt conveyors, or screw conveyors, each engineered to maintain the noise reduction benefits of the shredding process.

Specialized Rotors

Select from three rotor types: standard configuration, specialized design for plastic films or flexible materials, or heavy-duty version for challenging and hard objects.

MAIKONG’s comprehensive range of low speed high torque shredders

Find Your Ideal Shredder Solution

Contact our technical team to discuss your specific requirements and noise reduction goals.

Get Expert Recommendation

Maintenance Advantages of Low Speed Operation

Beyond noise reduction, low speed high torque shredders offer significant maintenance benefits that translate to lower operating costs and increased uptime.

Easy maintenance access on MAIKONG’s low speed high torque shredder

Reduced Wear and Extended Component Life

The low-speed operation fundamentally changes the wear patterns on critical components:

- Slower blade rotation significantly reduces friction and heat generation

- Lower impact forces extend blade life by up to 40% compared to high-speed systems

- Reduced vibration minimizes stress on bearings and structural components

- Cooler operation prevents thermal stress on hydraulic components and seals

- Controlled material processing reduces unexpected impacts and overloads

Simplified Maintenance Procedures

MAIKONG’s low speed high torque shredders are designed for easy maintenance:

Accessible Design

Large access panels provide clear pathways to all maintenance points. The cutting chamber features a hydraulic opening system for complete access during blade changes or cleaning operations.

Modular Components

Detachable cutting heads make maintenance and replacement of wearing parts easier and significantly reduce downtime. Individual blades can be rotated or replaced without removing the entire shaft assembly.

“We’ve reduced our maintenance costs by nearly 30% since switching to MAIKONG’s low speed high torque shredder. The blades last longer, and when we do need to service the machine, it’s much more straightforward than our previous high-speed system.”

– Maintenance Manager, Plastic Recycling Facility

Explore Replacement Parts

Philippine Success Stories

Businesses across the Philippines have experienced significant benefits after implementing MAIKONG low speed high torque shredders for their plastic processing operations.

Manila Recycling Facility

A large recycling operation in Manila replaced three high-speed shredders with two MAIKONG MK-1000 low speed high torque units. The results were immediate:

- Noise levels reduced by 18 decibels throughout the facility

- Eliminated need for mandatory hearing protection in adjacent work areas

- 25% reduction in energy consumption

- Increased throughput despite fewer machines

- Significantly reduced dust generation

Cebu Manufacturing Plant

A plastic products manufacturer in Cebu installed a MAIKONG MK-800 to process production scrap and rejected parts. The company reported:

- Ability to operate the shredder in the main production area without noise disruption

- Improved material reclamation rate due to more consistent output size

- 40% reduction in maintenance costs compared to previous high-speed equipment

- Enhanced workplace satisfaction and communication

- Elimination of complaints from neighboring businesses

Transform Your Plastic Processing with Reduced Noise

MAIKONG’s low speed high torque shredders represent a significant advancement in plastic processing technology, offering Philippine businesses a superior alternative to conventional high-speed equipment. By dramatically reducing operational noise while maintaining exceptional performance, these innovative machines create healthier workplaces, improve regulatory compliance, and enhance overall operational efficiency.

The unique combination of powerful torque and reduced speed delivers multiple benefits beyond noise reduction, including lower energy consumption, decreased maintenance requirements, reduced dust generation, and extended component life. For plastic processing facilities looking to optimize their operations while creating a better working environment, MAIKONG’s low speed high torque technology provides the ideal solution.