In the world of plastic recycling and waste management, choosing the right equipment is crucial for operational efficiency and cost-effectiveness. Plastic shredders, crushers, and grinders each serve specific functions in the plastic size reduction process, but understanding their differences is essential for making informed decisions. This comprehensive guide explores the distinct characteristics, applications, and benefits of each machine type, helping you determine which solution best fits your plastic processing needs in the Philippines.

Plastic Shredders, Crushers, and Grinders

Before diving into the specific differences, it’s important to understand that these three machine types represent different approaches to plastic size reduction. While they may seem similar at first glance, each has unique mechanisms, output capabilities, and ideal applications that make them suitable for different stages of the plastic recycling process.

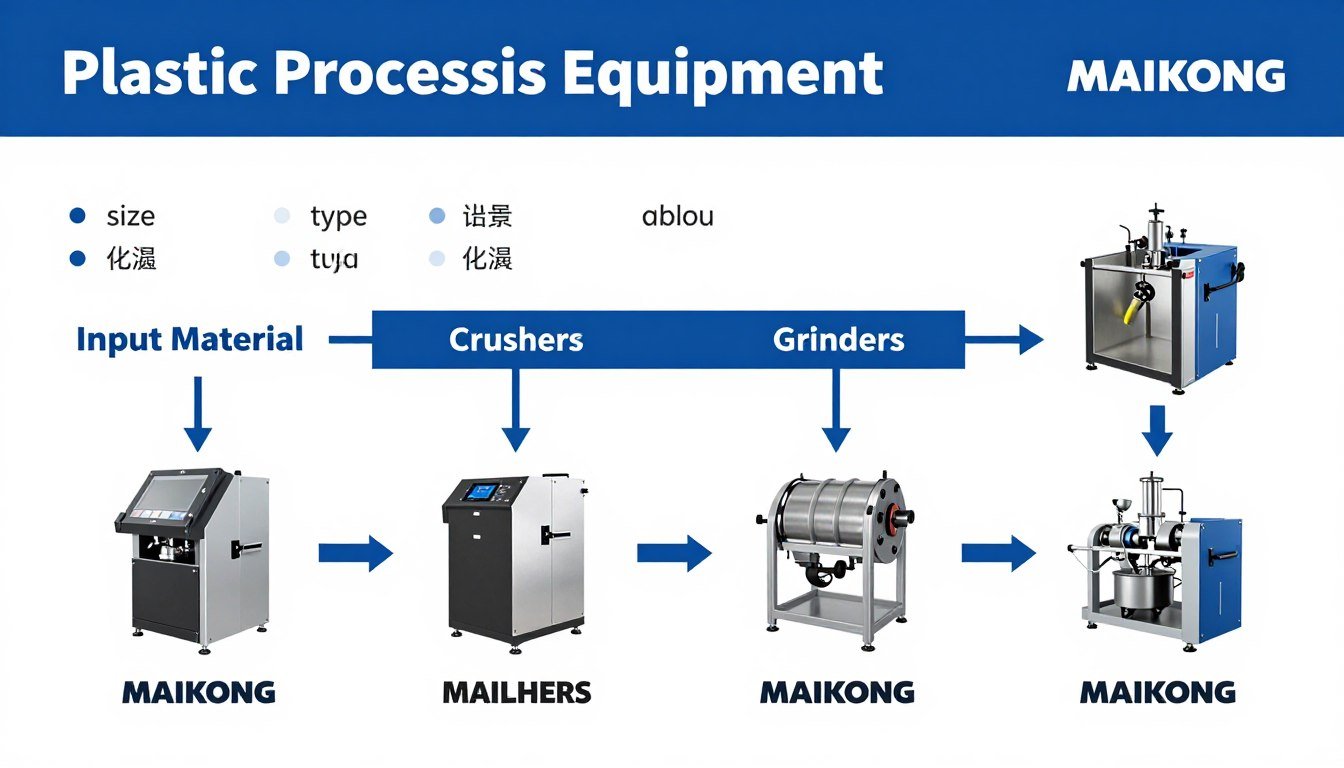

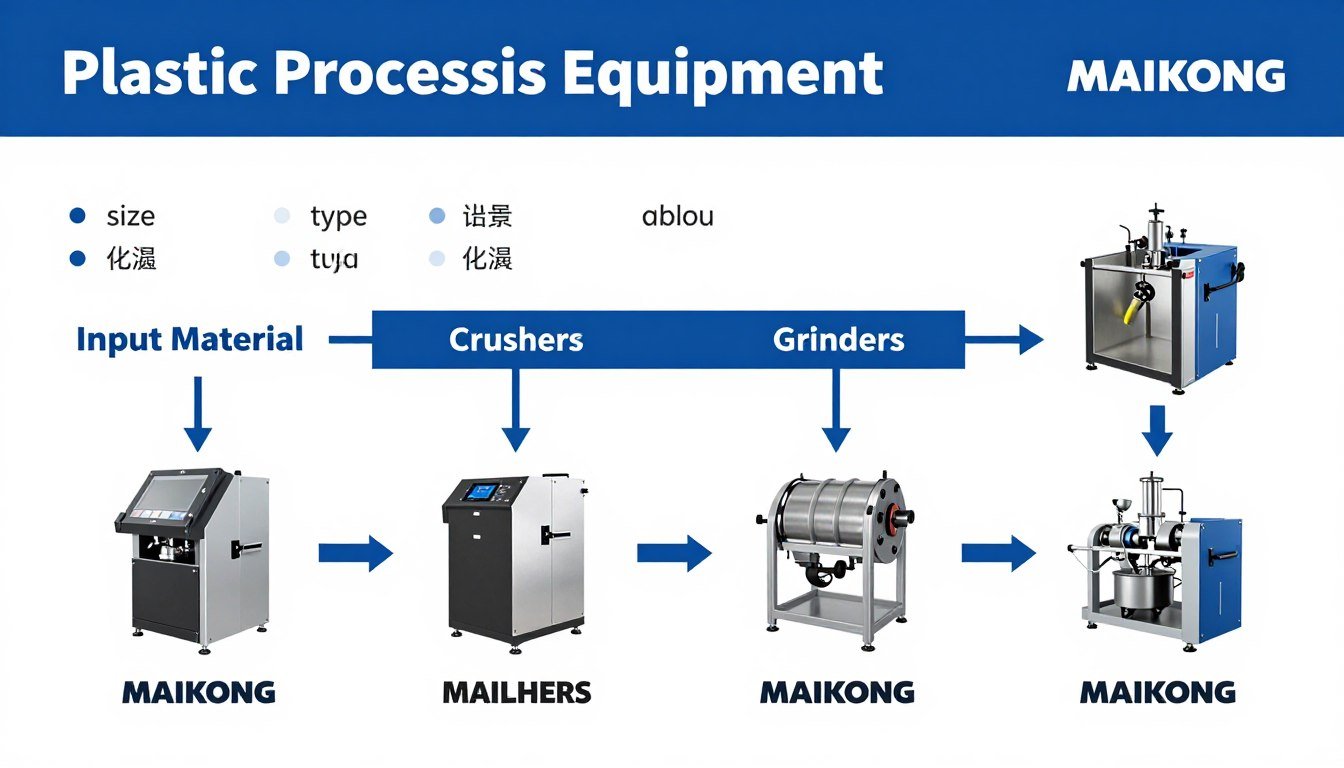

Different plastic size reduction machines manufactured by MAIKONG

Plastic Shredders

Plastic shredders are heavy-duty machines designed to reduce large plastic items into smaller, manageable pieces. They typically feature rotating blades or cutting disks mounted on one or more shafts that tear and cut materials. Plastic shredders are often the first step in the recycling process, handling bulky items that other machines cannot process.

Plastic Crushers

Plastic crushers use compression and impact forces to break down plastic materials. Unlike shredders that cut materials, crushers employ hammers or compression mechanisms to smash plastics into smaller pieces. They’re particularly effective for brittle plastics and can produce relatively uniform output sizes.

Plastic Grinders

Plastic grinders utilize abrasion and cutting to reduce plastic materials to fine particles or granules. They typically feature a grinding chamber with rotating blades that cut against stationary blades or screens. Grinders are often used as secondary processors after initial size reduction by shredders or crushers.

Deep Dive: Plastic Shredders

Plastic shredders are versatile workhorses in the recycling industry, capable of handling a wide range of plastic materials and sizes. Let’s explore their key characteristics, types, and applications.

Types of Plastic Shredders

MAIKONG dual-shaft industrial plastic shredder in operation

Single-Shaft Shredders

Single-shaft plastic shredders feature one rotating shaft with cutting blades that operate against stationary counter knives. They’re ideal for processing homogeneous materials and offer consistent output sizes. MAIKONG’s plastic shredder line includes versatile single-shaft models suitable for various applications.

Double-Shaft Shredders

Double-shaft plastic shredders utilize two counter-rotating shafts with interlocking cutters. This design creates a powerful shearing action that can process tougher materials and larger items. Our industrial plastic shredder range features robust double-shaft models for demanding applications.

Four-Shaft Shredders

Four-shaft plastic shredders represent the most powerful configuration, with two primary cutting shafts and two secondary shafts that further reduce material size. These machines excel at processing difficult materials and producing smaller, more uniform output.

Specialized Shredders

Some plastic shredders are designed for specific applications, such as our mini plastic shredder machine for smaller operations or our specialized bottle shredders for PET recycling.

Key Features of Quality Plastic Shredders

- Robust Cutting System: High-quality alloy steel blades and cutters that can withstand continuous operation

- Adjustable Cutting Gap: Ability to modify the distance between cutting elements for different materials

- Hydraulic Ram: Forced feeding mechanism to push materials into the cutting chamber

- Screen System: Interchangeable screens to control output particle size

- Overload Protection: Automatic reverse function when detecting uncrushable materials

- Low Noise Operation: Insulated housing and precision engineering to reduce operational noise

- Easy Maintenance Access: Hydraulic opening systems for quick blade changes and maintenance

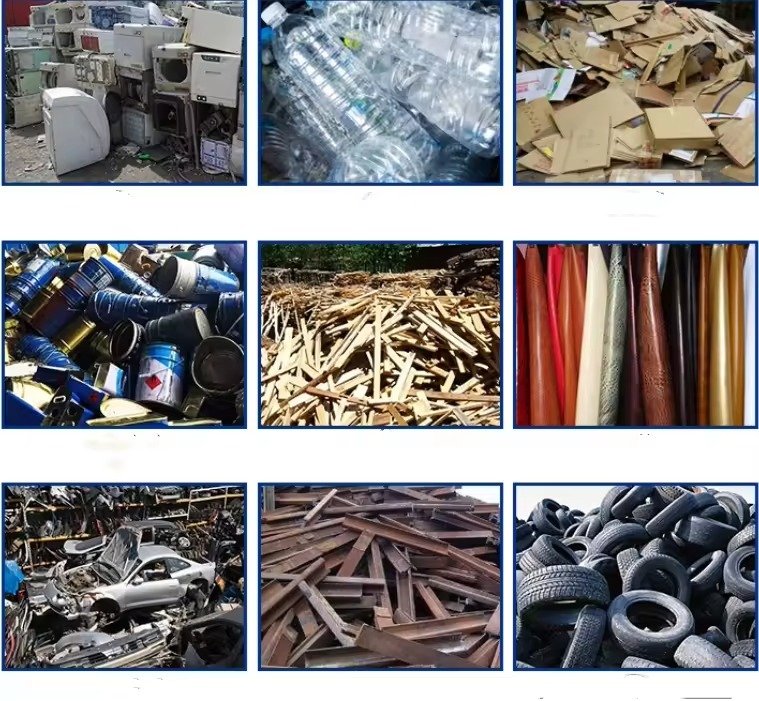

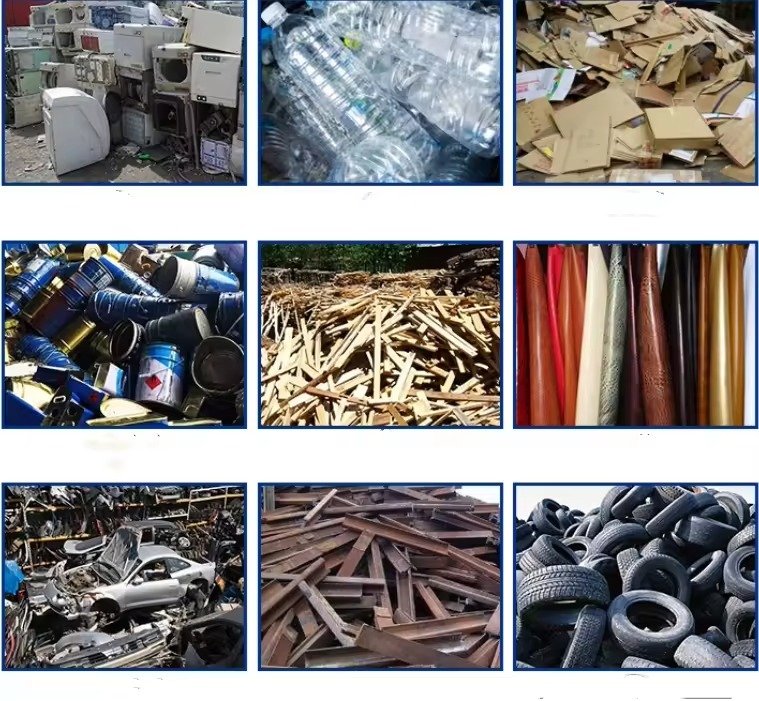

Ideal Applications for Plastic Shredders

Before and after: Plastic waste processed through MAIKONG shredders

| Plastic Type |

Common Forms |

Ideal Shredder Type |

Output Size |

| HDPE (#2) |

Bottles, containers, pipes, crates |

Double-shaft |

20-50mm |

| PET (#1) |

Bottles, packaging |

Single-shaft |

15-30mm |

| PVC (#3) |

Pipes, profiles, siding |

Double or four-shaft |

25-60mm |

| LDPE/LLDPE (#4) |

Films, bags, flexible packaging |

Specialized film shredder |

25-40mm |

| PP (#5) |

Containers, automotive parts, crates |

Double-shaft |

20-50mm |

| PS (#6) |

Packaging, disposable items |

Single-shaft |

15-30mm |

Plastic Crushers: Characteristics and Applications

Plastic crushers represent another approach to size reduction, utilizing compression and impact forces rather than cutting. Understanding their unique properties helps determine when they’re the optimal choice for your plastic processing needs.

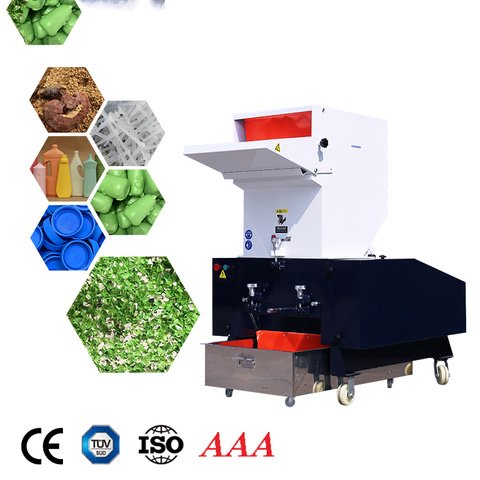

MAIKONG plastic crusher processing rigid plastic materials

How Plastic Crushers Work

Unlike plastic shredders that primarily cut materials, crushers employ hammers, impact plates, or compression mechanisms to break plastics through force. This approach is particularly effective for brittle materials that respond well to impact forces.

Hammer Crushers

Hammer crushers feature rotating hammers that strike plastic materials against impact plates or anvils. The high-speed impact fractures the plastic into smaller pieces, which then pass through a screen that controls output size.

Jaw Crushers

Jaw crushers use a moving jaw that compresses material against a fixed jaw. This compression action is effective for breaking down rigid plastics and can handle larger initial feed sizes than some other crusher types.

Impact Crushers

Impact crushers use high-speed rotors with attached hammers or bars to strike materials, breaking them through impact rather than compression. They’re known for producing more cubical output particles compared to other crusher types.

Roll Crushers

Roll crushers employ two counter-rotating cylinders to compress and crush materials passing between them. The gap between rollers determines output size, making these machines highly adjustable for different applications.

When to Choose a Crusher Over a Shredder

Advantages of Crushers

- More energy-efficient for brittle materials

- Often produce more uniform particle sizes

- Lower maintenance costs due to fewer cutting edges

- Better handling of abrasive materials that would quickly dull shredder blades

- Typically operate at higher throughput rates for certain materials

Limitations of Crushers

- Less effective for flexible or elastic materials

- May struggle with very large items without pre-processing

- Can generate more dust during operation

- Often louder than equivalent shredders

- Less precise control over output shape (though size can be controlled)

Ideal Applications for Plastic Crushers

Crushers excel in specific scenarios where their unique properties offer advantages over plastic shredders or grinders:

- Rigid Plastic Processing: Particularly effective for hard, brittle plastics like PS, ABS, and some grades of PC

- High-Volume Operations: When throughput is a priority for certain material types

- Abrasive Materials: When processing plastics with fillers that would quickly wear down shredder blades

- Energy Efficiency: When processing materials that break easily under impact, requiring less energy than cutting

- Uniform Sizing: When consistent particle size is critical for downstream processes

Plastic Grinders: Fine Processing Solutions

Plastic grinders represent the final stage in size reduction, transforming shredded or crushed materials into fine particles or granules suitable for reprocessing. Their precision and output quality make them essential for closing the recycling loop.

MAIKONG plastic grinder with visible grinding mechanism

How Plastic Grinders Work

Grinders utilize a combination of cutting, shearing, and sometimes impact forces to reduce plastic materials to fine, uniform particles. They typically feature a grinding chamber with rotating blades that cut against stationary elements or screens.

Granulators

Granulators are the most common type of plastic grinder, featuring a rotor with multiple blades that cut against bed knives. Material is fed into the cutting chamber and reduced until it’s small enough to pass through a screen, ensuring uniform output size.

Pulverizers

Pulverizers use high-speed impact to reduce materials to very fine particles. They’re typically used for producing powder-like output for specialized applications rather than standard recycling granules.

Knife Mills

Knife mills employ sharp, precision-ground knives mounted on a rotor that cuts against stationary knives. They excel at producing clean cuts with minimal dust and heat generation, making them ideal for temperature-sensitive plastics.

Disc Mills

Disc mills use abrasion between rotating and stationary discs to grind materials. They’re less common in plastic recycling but can be useful for certain specialized applications requiring very fine output.

When to Choose a Grinder

Comparison of output sizes: shredded (left), crushed (center), and ground (right) plastic

Advantages of Grinders

- Produce fine, uniform particles ideal for direct reprocessing

- Precise control over output size through screen selection

- Often include built-in classification systems for consistent quality

- Can process pre-reduced materials from shredders or crushers

- Produce higher-value output material that commands better market prices

Limitations of Grinders

- Typically cannot handle large initial feed sizes

- Higher energy consumption per unit of material processed

- More sensitive to contamination and non-plastic materials

- Higher wear rates on cutting components

- Often require pre-processing with shredders for larger items

Ideal Applications for Plastic Grinders

Grinders are typically the final stage in plastic size reduction, preparing materials for direct reuse in manufacturing:

- In-House Recycling: Manufacturing operations recycling their own scrap

- High-Value Plastics: When processing engineering or specialty plastics where quality is paramount

- Direct Reprocessing: When output will be directly fed into extruders or injection molding machines

- Clean Stream Processing: When working with pre-sorted, contaminant-free materials

- Small-Scale Operations: Our small plastic shredder and grinder combinations are ideal for businesses with limited space or processing needs

Choosing the Right Equipment for Your Needs

Selecting between plastic shredders, crushers, and grinders—or determining if you need a combination of these machines—depends on several key factors. This decision-making framework will help guide your selection process.

Decision framework for selecting the appropriate plastic processing equipment

Key Factors to Consider

Input Material Characteristics

- Size: Large items require shredders first

- Rigidity: Flexible materials favor shredders; brittle materials may suit crushers

- Contamination: Heavily contaminated materials need robust shredders

- Variety: Mixed materials may require multiple processing stages

Output Requirements

- Size: Finer outputs require grinders

- Uniformity: Consistent sizing may require multiple stages

- Volume: Higher throughput needs may influence machine selection

- End Use: Direct reprocessing requires higher quality output

Operational Considerations

- Space: Available facility space may limit options

- Budget: Initial investment vs. operational costs

- Energy: Power availability and efficiency concerns

- Maintenance: Accessibility of plastic shredder parts and service

Common Processing Configurations

| Configuration |

Process Flow |

Ideal Applications |

Advantages |

| Shredder Only |

Single-stage size reduction |

Basic volume reduction, preparation for transport |

Simplicity, lower initial investment, versatility |

| Shredder → Grinder |

Two-stage process for fine output |

In-house recycling, direct reprocessing |

High-quality output, efficient processing of various sizes |

| Crusher → Grinder |

Impact followed by precision cutting |

Rigid, brittle plastics requiring fine output |

Energy efficiency for suitable materials, uniform output |

| Shredder → Crusher → Grinder |

Complete three-stage processing |

Large, mixed materials requiring premium output |

Maximum versatility, highest quality output, optimal efficiency |

Expert Tip: Many operations benefit from starting with a quality plastic shredder and adding additional processing equipment as needs evolve and budget allows. MAIKONG’s modular systems are designed to integrate seamlessly as your operation grows.

MAIKONG Solutions for Philippine Businesses

At MAIKONG, we understand the unique challenges facing plastic recycling operations in the Philippines. Our comprehensive range of plastic shredders, crushers, and grinders is designed to meet the specific needs of the Philippine market.

MAIKONG’s state-of-the-art manufacturing facility in SZ, GD

Our Product Range

Specialized Equipment

- Plastic Bottle Shredders – Optimized for PET and HDPE bottles

- Film Shredders – Designed for challenging thin films and flexible packaging

- Pipe Shredders – Engineered for long, rigid PVC and HDPE pipes

- Custom Solutions – Tailored to specific material challenges

Support Services

- Plastic Shredder Parts – Genuine replacement components

- Technical Support – Expert assistance for installation and operation

- Maintenance Programs – Preventive maintenance to maximize uptime

- Operator Training – Comprehensive training for your team

Why Choose MAIKONG for Your Plastic Processing Needs

4.8

Customer Satisfaction

Equipment Durability

4.8/5

Processing Efficiency

4.7/5

After-Sales Support

4.9/5

“After comparing several manufacturers, we chose MAIKONG for our plastic recycling operation in Manila. Their industrial plastic shredder has exceeded our expectations in terms of throughput and reliability. The local support team has been responsive and helpful whenever we’ve needed assistance.”

— Roberto Santos, Operations Manager at Manila Recycling Solutions

Expert Consultation for Your Plastic Processing Needs

Not sure which solution is right for your operation? MAIKONG’s team of experts is ready to analyze your specific requirements and recommend the optimal equipment configuration. Contact us today for a personalized consultation.

Conclusion: Making the Right Choice for Your Plastic Recycling Needs

Understanding the differences between plastic shredders, crushers, and grinders is essential for making informed decisions about your plastic waste management and recycling operations. Each machine type offers distinct advantages and is suited to specific applications within the plastic recycling process.

For most operations, particularly those handling a variety of plastic waste types and sizes, a plastic shredder often serves as the foundation of an effective processing system. Crushers excel with brittle materials and high-volume operations, while grinders deliver the fine, uniform output needed for direct reprocessing.

At MAIKONG, we’re committed to helping businesses throughout the Philippines optimize their plastic recycling operations with high-quality, reliable equipment tailored to their specific needs. Whether you’re just starting your recycling journey or looking to upgrade existing systems, our team of experts is ready to provide the guidance and solutions you need.

Contact us today to discuss your plastic processing requirements and discover how MAIKONG’s plastic shredders, crushers, and grinders can help you achieve your recycling goals efficiently and cost-effectively.

Ready to Optimize Your Plastic Recycling Operation?

Explore our complete range of solutions or contact our team for personalized assistance.