The growing plastic waste crisis in the Philippines demands effective recycling solutions. Choosing between a single shaft and double shaft plastic shredder is a critical decision that impacts your operation’s efficiency, output quality, and bottom line. As a leading manufacturer, MAIKONG provides comprehensive guidance to help Philippine businesses select the ideal shredding technology for their specific needs. This detailed comparison will help you understand the fundamental differences, advantages, and ideal applications for each type of plastic shredder machine.

What is a Plastic Shredder and Why is it Essential?

A plastic shredder is specialized industrial equipment designed to break down various plastic materials into smaller, manageable pieces. These machines play a crucial role in plastic recycling processes, waste volume reduction, and preparing materials for further processing or repurposing.

MAIKONG industrial plastic shredder processing mixed plastic waste

The Problem of Plastic Waste: Lumps, Purges, and Scrap

Plastic manufacturing and processing operations in the Philippines generate significant waste in various forms:

- Failed prints and production rejects

- Plastic lumps formed during maintenance

- Purges created when switching materials or colors

- Runners and trims from injection molding

- Post-consumer plastic waste requiring recycling

Without proper recycling equipment, these materials often end up in landfills, contributing to the country’s growing waste management challenges. A plastic shredder machine transforms this problematic waste into a valuable resource.

How a Plastic Shredder Machine Turns Waste into Resource

The transformation process begins with size reduction through shredding. By breaking down bulky plastic items into uniform smaller pieces, a plastic shredder creates material that can be:

- Easily transported and stored (reduced volume)

- Efficiently washed and sorted

- Properly melted and extruded into new products

- Sold as valuable regrind material

Ready to Start Recycling Your Plastic Waste?

MAIKONG offers a complete range of plastic shredder solutions for Philippine businesses of all sizes.

Explore Our Plastic Shredders

Common Types of Plastic Waste for Shredding

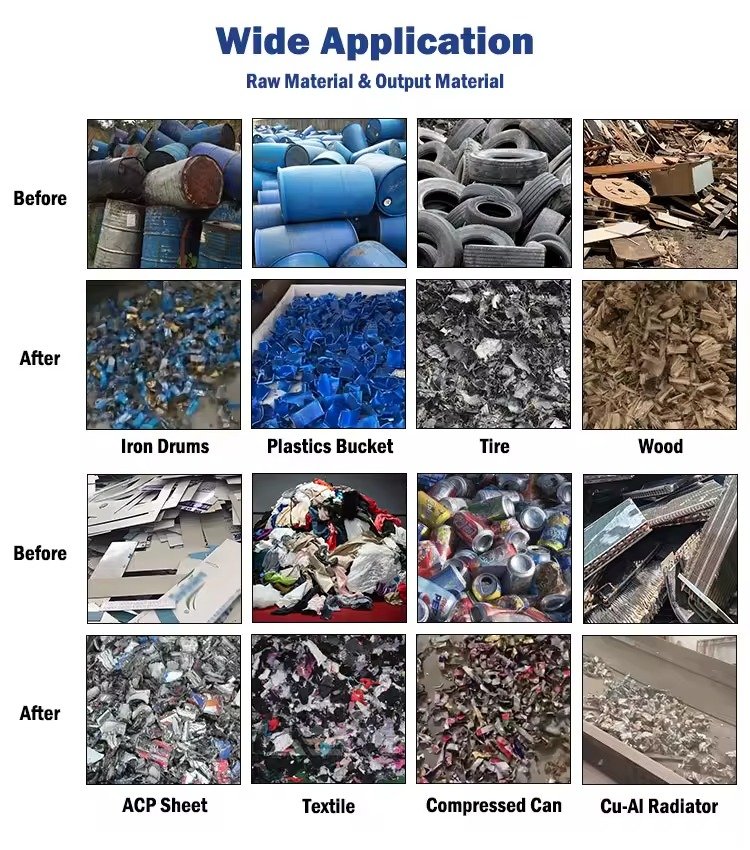

MAIKONG plastic shredders can process a wide range of plastic materials commonly found in Philippine industries:

| Plastic Type |

Examples |

Characteristics |

| HDPE (#2) |

Plastic totes, crates, bottles, buckets, containers |

Rigid, durable, excellent for recycling |

| LDPE (#4) |

Plastic film, cups, lids, flexible containers |

Flexible, requires specialized cutting |

| PVC (#3) |

Window trim, fencing, siding, pipe |

Tough, requires robust shredding power |

| PP (#5) |

Trays, tanks, caps, automotive parts |

Heat-resistant, widely recyclable |

Understanding Shredder Technology: Single Shaft vs. Double Shaft

The fundamental difference between single shaft and double shaft plastic shredders lies in their cutting mechanism design, which affects their performance characteristics and ideal applications.

How a Single Shaft Plastic Shredder Works

A single shaft plastic shredder operates with one primary rotating shaft equipped with cutting blades that rotate against stationary counter-knives.

Single shaft plastic shredder mechanism with hydraulic ram and screen

- Cutting Principle: Material is pushed against the rotating blades by a hydraulic ram

- Screen System: Sized mesh screens control output particle size

- Operation: Continuous cutting against a fixed bed knife

- Speed: Typically operates at medium to high RPM

How a Double Shaft Plastic Shredder Machine Works

A double shaft plastic shredder machine features two counter-rotating shafts with interlocking cutting discs that create a scissors-like cutting action.

Double shaft plastic shredder with counter-rotating cutting system

- Cutting Principle: Shearing action between counter-rotating blades

- No Screen: Output size determined by blade spacing

- Operation: Self-feeding with automatic reversing capability

- Speed: Typically operates at lower RPM with high torque

Head-to-Head Comparison: Single Shaft vs. Double Shaft

When selecting the right plastic shredder for your Philippine operation, consider these key performance factors:

Throughput Capacity and Efficiency

Single Shaft Advantages

- Higher throughput for homogeneous materials

- More efficient for high-volume processing

- Better for continuous operation

Double Shaft Advantages

- Handles mixed materials more effectively

- Better for batch processing

- Excellent for pre-shredding before granulation

Material Suitability and Versatility

| Material Type |

Single Shaft Performance |

Double Shaft Performance |

| Thin Films/Bags |

Good with specialized rotor |

Excellent – prevents wrapping |

| Hard Lumps/Purges |

Excellent with proper ram force |

Good for initial breaking |

| Hollow Containers |

Good with proper feeding |

Excellent – crushes efficiently |

| Mixed Materials |

Fair – may require pre-sorting |

Excellent – handles variety |

Particle Size Consistency and Output Control

The consistency of output size is crucial for downstream processing:

Single Shaft Systems:

- Produces more uniform particle size

- Screen system allows precise size control

- Ideal when consistent output is critical

- Size changes require screen replacement

Double Shaft Systems:

- Output size varies more widely

- Size determined by blade spacing

- Better for primary size reduction

- Often requires secondary processing

Energy Consumption and Operational Costs

Operating costs are a major consideration for Philippine businesses:

Single Shaft Considerations:

- Higher initial power consumption

- More efficient for continuous operation

- Lower wear on cutting components

- Higher throughput can reduce per-ton costs

Double Shaft Considerations:

- Lower power consumption per cycle

- More efficient for intermittent use

- Higher maintenance on cutting elements

- Better energy efficiency with tough materials

Maintenance, Blade Life, and Durability

Long-term reliability is essential for maximizing your investment:

Single Shaft Maintenance:

- Fewer cutting elements to maintain

- Longer intervals between blade changes

- Screen replacement is additional maintenance

- Hydraulic system requires regular service

Double Shaft Maintenance:

- More cutting elements to maintain

- Blades can be rotated to extend life

- No screen system to maintain

- Simpler mechanical design overall

Regular maintenance ensures optimal performance and longevity of your plastic shredder

Noise Levels and Operational Environment

Workplace conditions matter for your facility and staff:

Single Shaft Characteristics:

- Generally higher noise levels

- Requires more robust foundations

- Higher vibration during operation

- Often needs dedicated space

Double Shaft Characteristics:

- Lower operating noise

- Less vibration during operation

- Can often be installed in production areas

- More suitable for mixed-use spaces

Choosing the Right Shredder for Your Philippine Business

Based on MAIKONG’s extensive experience serving the Philippine market, we recommend considering these factors when selecting between single and double shaft plastic shredders:

When to Choose a Single Shaft Industrial Plastic Shredder

A single shaft industrial plastic shredder is ideal for:

- High-volume operations processing consistent materials

- Applications requiring precise particle sizing for downstream processes

- Continuous production environments with steady material flow

- Operations focused on rigid plastics like HDPE, PP, or PVC

- Facilities with existing granulation systems requiring properly sized feed

Need a High-Capacity Industrial Solution?

MAIKONG’s industrial plastic shredders deliver reliable performance for demanding applications.

View Industrial Shredders

When to Choose a Double Shaft Plastic Crusher Machine

A double shaft plastic crusher machine is preferable for:

- Operations handling diverse material streams with minimal sorting

- Processing challenging materials like films, fibers, and mixed plastics

- Facilities with space constraints requiring compact equipment

- Applications where noise reduction is important

- Batch processing operations with intermittent usage patterns

Case Studies: Applications for Each Type

Single Shaft Success: Manila Packaging Manufacturer

A packaging manufacturer in Manila implemented a MAIKONG single shaft plastic shredder to process production scrap from their thermoforming lines. The consistent output size allowed direct reintroduction into their production process, reducing virgin material costs by 22%.

Double Shaft Solution: Cebu Recycling Facility

A recycling operation in Cebu chose a MAIKONG double shaft plastic shredder machine to handle mixed post-consumer plastics. The system’s ability to process everything from films to bottles without jamming increased their processing capacity by 35%.

Have Mixed Plastic Waste Streams?

Our double shaft systems excel at processing diverse materials with minimal pre-sorting.

Explore Our Solutions

Beyond the Shredder: Customization and Add-ons by MAIKONG

MAIKONG offers numerous customization options to optimize your plastic shredder for specific applications:

Infeed Systems (Conveyors, Hoppers)

- Conveyor Systems: Automatic material infeed via belt or screw conveyors

- Inclined Chutes: Facilitate loading with forklift or crane

- Custom Hoppers: Designed for specific material types and volumes

- Vertical Pushers: Force-feed materials against the rotor for increased efficiency

Output Handling (Cyclones, Conveyors)

Efficient material collection systems improve workflow:

- Cyclone Collection: Pneumatic transport with dust separation

- Belt Conveyors: Transport shredded material to storage or next process

- Screw Conveyors: Controlled movement of shredded materials

- Bagging Systems: Direct packaging of processed material

Special Rotors for Films or Hard Materials

MAIKONG offers specialized rotor designs:

Specialized Rotor Options:

- Standard multi-purpose rotors

- Film-specific designs to prevent wrapping

- Heavy-duty rotors for challenging materials

- Custom configurations for unique applications

Control Systems and Safety Features

Advanced controls enhance operation and safety:

- PLC Control Systems: Programmable logic for automated operation

- Auto-Reverse Function: Automatically clears jams and prevents damage

- Remote Monitoring: Track performance metrics and maintenance needs

- Safety Interlocks: Prevent operation when access doors are open

Need a Customized Shredding Solution?

MAIKONG engineers can design a system tailored to your specific requirements.

Email for Custom Solutions

MAIKONG’s Product Range for Every Need

From compact units to industrial powerhouses, MAIKONG offers a complete range of plastic shredder solutions:

Heavy-Duty Industrial Plastic Shredder Solutions

Our industrial plastic shredder line features:

- Processing capacities from 500 kg/hr to 5,000+ kg/hr

- Heavy-duty construction for 24/7 operation

- Advanced PLC control systems with remote monitoring

- Available in both single and double shaft configurations

- Customizable for specific industry applications

Ready for Industrial-Scale Recycling?

Our heavy-duty shredders handle the most demanding applications.

View Industrial Models

Compact Mini Plastic Shredder Machine and Small Plastic Shredder for SMEs

Our smaller units provide efficient solutions for lower volume needs:

Mini Plastic Shredder Features:

- Compact footprint for limited spaces

- Processing capacities from 50-300 kg/hr

- Single-phase power options available

- Ideal for small recycling operations

- Easy maintenance and operation

Reliable Plastic Shredder Parts for Maintenance

MAIKONG ensures long-term operation with quality replacement parts:

- Genuine plastic shredder parts manufactured to original specifications

- Cutting blades made from premium alloy steel for extended life

- Screens in various sizes for precise output control

- Drive components, bearings, and hydraulic system parts

- Fast shipping throughout the Philippines

Keep Your Shredder Running at Peak Performance

Genuine MAIKONG parts ensure reliability and optimal operation.

Order Replacement Parts

Conclusion: Your Next Step with MAIKONG

Selecting between a single shaft and double shaft plastic shredder depends on your specific material stream, production requirements, and operational environment. Both technologies offer distinct advantages for different applications in the Philippine market.

Single shaft systems excel at producing consistent output with high throughput for homogeneous materials, while double shaft systems offer superior versatility for mixed materials and challenging items like films and fibers.

As the Philippines’ trusted partner in plastic recycling solutions, MAIKONG provides expert guidance to help you select the perfect plastic shredder machine for your unique needs. Our engineering team can analyze your specific requirements and recommend a customized solution that maximizes efficiency and return on investment.

Visit plasticshredder.ph to explore our complete range of plastic recycling solutions, or learn more about MAIKONG’s commitment to quality and our network of distributors throughout the Philippines.