In today’s environmentally conscious world, efficient waste management has become a critical concern for Philippine industries. At the forefront of this revolution stands the plastic shredder – a powerful solution transforming how businesses handle plastic waste. From reducing disposal costs to creating new revenue streams through recycling, these machines are changing the industrial landscape across the Philippines. This comprehensive guide explores everything you need to know about plastic shredders, their applications, and how MAIKONG’s cutting-edge technology is helping Philippine businesses achieve sustainability goals while improving their bottom line.

Understanding Plastic Shredders: The Foundation of Recycling

MAIKONG plastic shredder processing industrial waste

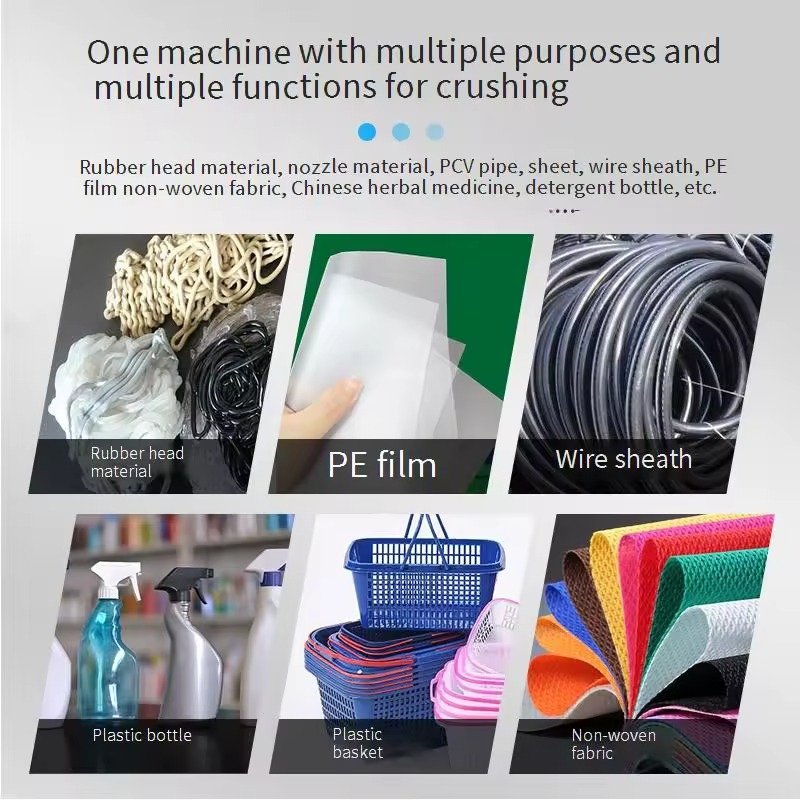

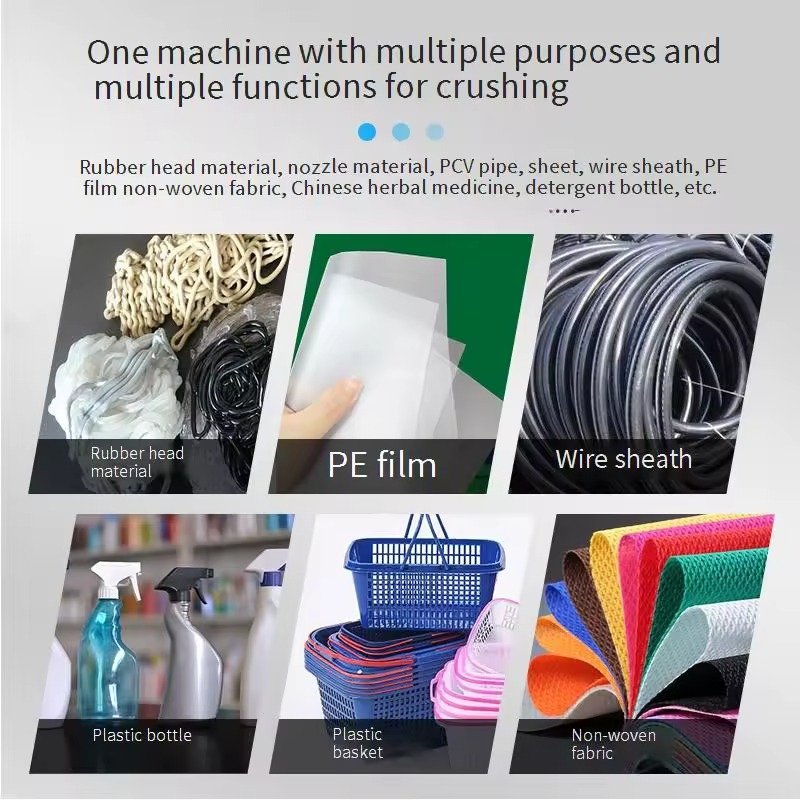

A plastic shredder is a specialized industrial machine designed to reduce plastic materials into smaller, manageable pieces. These machines serve as the crucial first step in the plastic recycling process, breaking down various plastic products into uniform sizes that can be further processed, reused, or repurposed. In Philippine manufacturing facilities, where plastic waste generation is significant, plastic shredders play a vital role in waste volume reduction and resource recovery.

How Plastic Shredders Work

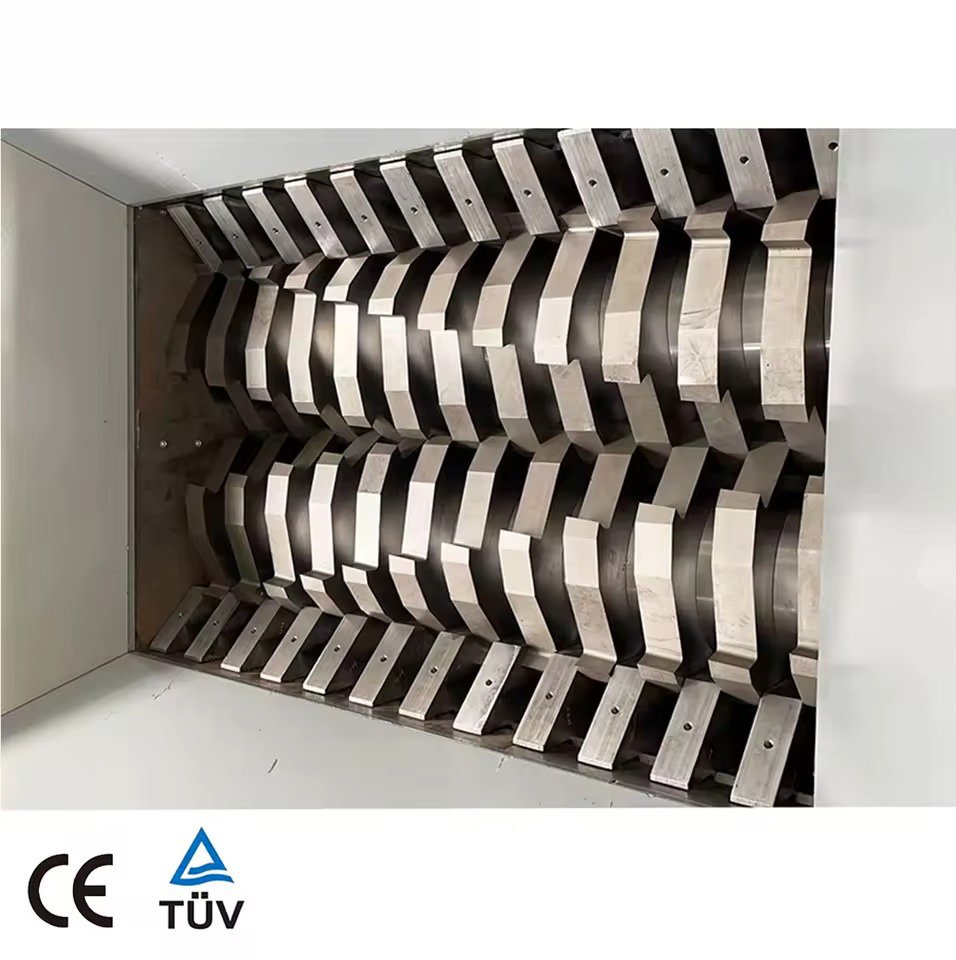

At their core, plastic shredders operate using a simple yet effective mechanical principle. The machine features rotating blades or cutting mechanisms that tear, cut, or shear plastic materials into smaller fragments. Depending on the model and configuration, these machines can process various types of plastics, from soft films to rigid containers. The MAIKONG plastic shredder line utilizes advanced cutting technology with specially designed rotors and blades to ensure efficient processing of diverse plastic waste streams common in Philippine industries.

Key Components of a Plastic Shredder

- Feeding hopper or conveyor system

- Cutting chamber with rotor and blades

- Drive system (electric or hydraulic)

- Control panel with safety features

- Output collection system

- Screening system for size control

Internal components of MAIKONG shredder technology

Types of Plastic Shredders Available in the Philippines

The Philippine market offers various plastic shredder types, each designed for specific applications and material types. Understanding these differences is crucial for selecting the right equipment for your industrial needs.

Single-Shaft Shredders

Single-shaft plastic shredders feature one rotating shaft with multiple cutting blades. These machines excel at processing larger plastic items and are ideal for initial size reduction. MAIKONG’s single-shaft models offer robust performance for Philippine manufacturing facilities dealing with bulky plastic waste.

Double-Shaft Shredders

Double-shaft models utilize two counter-rotating shafts with interlocking blades, creating a powerful shearing action. These plastic shredders are excellent for tough materials like HDPE pipes and thick plastic sheets commonly used in Philippine industrial applications.

Four-Shaft Shredders

Four-shaft plastic shredders represent the most advanced shredding technology, featuring four interlocking cutting shafts. These machines produce consistently sized output and are perfect for applications requiring fine granulation in specialized Philippine recycling operations.

Size Classifications for Philippine Markets

Mini Plastic Shredder Machine

Compact units ideal for small-scale operations, laboratories, or businesses with limited space and processing needs. These units are perfect for Philippine SMEs beginning their recycling journey.

Small Plastic Shredder

Mid-sized units balancing capacity and footprint, perfect for medium-scale Philippine manufacturing facilities with moderate plastic waste volumes requiring regular processing.

Industrial Plastic Shredder

Heavy-duty machines designed for continuous, high-volume processing in large Philippine industrial settings, recycling facilities, or manufacturing plants with significant plastic waste generation.

Common Plastic Waste Types in Philippine Industries

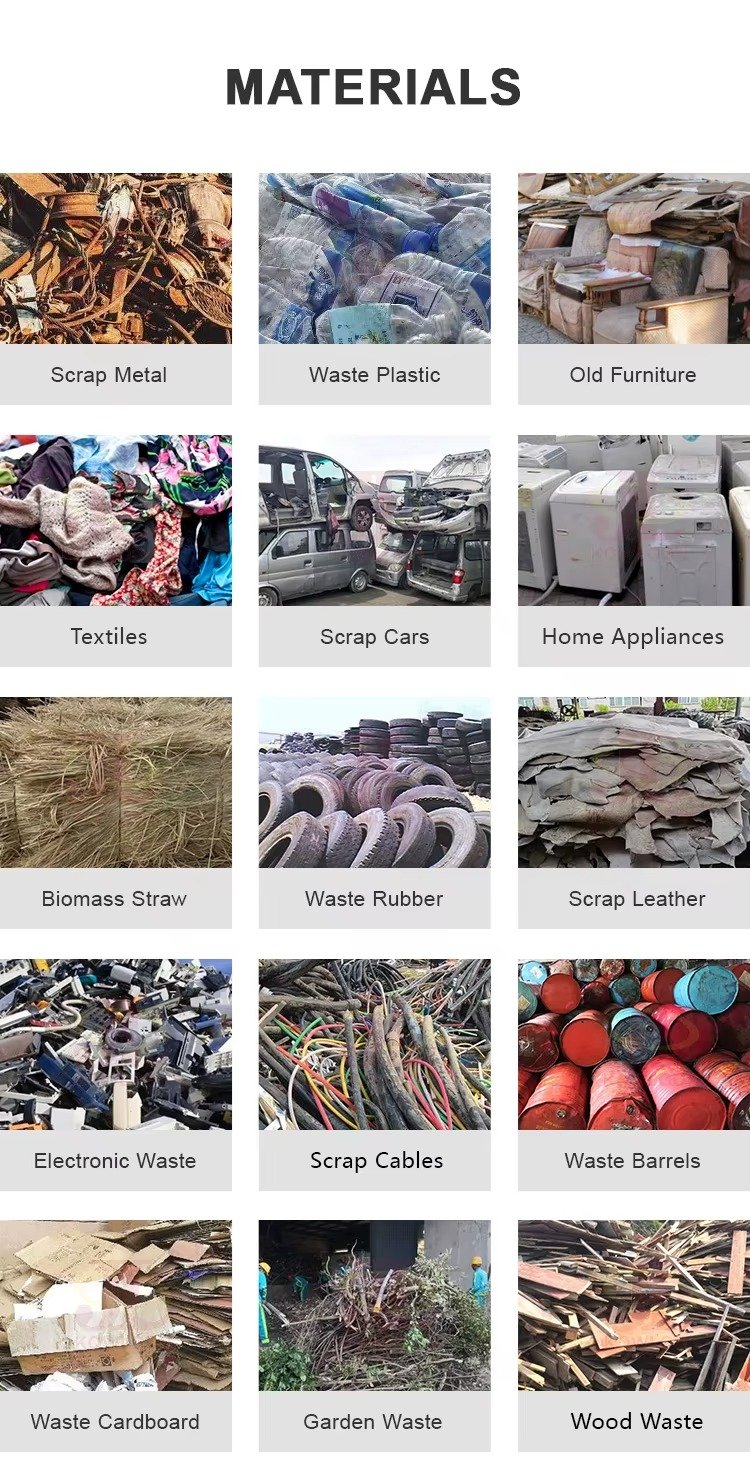

Understanding the different types of plastic waste is essential for selecting the appropriate plastic shredder for your specific needs. Philippine industries generate various plastic waste streams, each with unique properties and recycling requirements.

| Plastic Type |

Common Sources in Philippines |

Properties |

Recommended Shredder |

| PET (#1) |

Beverage bottles, food containers |

Rigid, transparent, food-safe |

Plastic bottle shredder, Single-shaft |

| HDPE (#2) |

Milk jugs, detergent bottles, pipes |

Rigid, chemical-resistant |

Industrial plastic shredder, Double-shaft |

| PVC (#3) |

Pipes, vinyl flooring, medical equipment |

Durable, chemical-resistant |

Heavy-duty plastic shredder machine |

| LDPE (#4) |

Plastic bags, packaging films |

Flexible, lightweight |

Specialized film plastic shredder |

| PP (#5) |

Food containers, automotive parts |

Heat-resistant, chemical-resistant |

Multi-purpose plastic crusher machine |

| PS (#6) |

Disposable cups, packaging |

Brittle, lightweight |

Small plastic shredder |

Not Sure Which Plastic Shredder You Need?

Our experts can help you identify the perfect solution for your specific plastic waste stream. Contact MAIKONG today for a personalized consultation.

Contact Our Experts

Benefits of Implementing a Plastic Shredder in Philippine Facilities

Economic Benefits

- Reduced Disposal Costs: By reducing waste volume, Philippine businesses can significantly lower waste management expenses.

- Material Recovery Value: Shredded plastic becomes a valuable resource that can be sold or reused in-house.

- Lower Raw Material Costs: Recycling plastic through a plastic shredder reduces the need for purchasing virgin materials.

- Operational Efficiency: MAIKONG shredders optimize space utilization and streamline waste handling processes.

Environmental Benefits

- Reduced Landfill Impact: Less plastic waste sent to Philippine landfills means reduced environmental contamination.

- Lower Carbon Footprint: On-site recycling reduces transportation emissions associated with waste disposal.

- Resource Conservation: Recycling plastic conserves the petroleum resources used in virgin plastic production.

- Compliance with Regulations: Helps meet Philippine environmental regulations and sustainability goals.

“Implementing a MAIKONG plastic shredder in our facility reduced our waste disposal costs by 40% while creating a new revenue stream from selling processed materials. The return on investment was achieved in just 14 months.”

— Production Manager, Leading Philippine Manufacturing Company

Key Applications of Plastic Shredders in Philippine Industries

Plastic shredders serve diverse applications across Philippine industrial sectors. Here’s how different industries benefit from this technology:

Manufacturing Industry

- Processing production scrap and rejects

- Recycling packaging materials

- Managing start-up lumps and purges

- Handling injection molding waste

Recycling Operations

- Processing post-consumer plastic waste

- Preparing materials for further recycling

- Volume reduction for transport

- Specialized processing of different plastic types

Packaging Industry

- Recycling film and flexible packaging

- Processing rigid packaging waste

- Managing production overruns

- Handling obsolete packaging materials

Specialized Applications in Philippine Context

Agricultural Sector

In the Philippine agricultural sector, plastic shredders process irrigation pipes, mulch films, and plant pots. MAIKONG’s specialized agricultural models handle these materials efficiently despite dirt contamination and UV degradation.

Fisheries and Aquaculture

The Philippines’ extensive fisheries industry generates significant plastic waste from nets, buoys, and packaging. MAIKONG industrial plastic shredders are designed to handle these tough, salt-exposed materials for effective recycling.

How to Choose the Right Plastic Shredder for Your Philippine Business

Selecting the appropriate plastic shredder requires careful consideration of several factors specific to your operation’s needs and constraints. Here’s a comprehensive guide to making the right choice:

Key Factors to Consider

- Material Type: Different plastics require specific shredder configurations

- Volume Requirements: Match capacity to your waste generation rate

- Output Size Needs: Consider your end-use requirements for the shredded material

- Space Constraints: Evaluate available floor space in your facility

- Power Availability: Ensure your facility can support the shredder’s power requirements

- Budget Considerations: Balance initial investment with long-term benefits

- Maintenance Requirements: Consider ongoing maintenance needs and parts availability

Common Mistakes to Avoid

- Undersizing: Choosing a shredder too small for your volume needs

- Overlooking Material Compatibility: Not all shredders handle all plastic types

- Ignoring Maintenance Access: Difficult maintenance leads to downtime

- Focusing Only on Initial Cost: Overlooking long-term operational expenses

- Neglecting Safety Features: Compromising on essential safety mechanisms

- Disregarding Future Needs: Failing to account for business growth

- Skipping Supplier Reputation: Not researching the manufacturer’s track record

MAIKONG’s Consultation Approach

At MAIKONG, we understand that choosing the right plastic shredder is a significant decision. Our experts work closely with Philippine businesses to assess their specific needs and recommend the most appropriate solution. We consider factors such as:

- Current and projected waste volumes

- Material composition analysis

- Facility layout and space constraints

- Power infrastructure assessment

- Operational goals and objectives

- Budget parameters and ROI expectations

- Integration with existing systems

- Future expansion possibilities

Need Help Selecting the Perfect Plastic Shredder?

Our team of experts is ready to analyze your specific requirements and recommend the ideal MAIKONG solution for your Philippine operation.

Request Expert Consultation

Maintenance and Optimization of Your Plastic Shredder

Proper maintenance is crucial for ensuring the longevity and optimal performance of your plastic shredder. MAIKONG machines are designed for reliability, but regular maintenance will maximize uptime and processing efficiency.

Essential Maintenance Practices

- Regular Blade Inspection: Check cutting blades for wear and damage; rotate or replace as needed.

- Lubrication Schedule: Maintain proper lubrication of all moving parts according to the manufacturer’s recommendations.

- Drive System Checks: Inspect belts, chains, and motors for proper tension and alignment.

- Cleaning Procedures: Remove accumulated debris from the cutting chamber and screens.

- Safety System Verification: Test all safety interlocks and emergency stops regularly.

Regular maintenance ensures optimal performance and longevity

MAIKONG Maintenance Tip: Keep a log of all maintenance activities, including blade rotations and replacements, to track wear patterns and optimize maintenance schedules.

Plastic Shredder Parts and Replacement

Understanding the critical components of your plastic shredder and having access to quality replacement parts is essential for minimizing downtime. MAIKONG provides comprehensive support for all plastic shredder parts to Philippine customers.

Cutting Blades

The most frequently replaced components due to wear. MAIKONG offers hardened steel blades with various tooth configurations optimized for different plastic types common in Philippine industries.

Screens and Sieves

Control the output size of shredded material. We offer various perforation sizes to meet specific requirements for Philippine recycling and manufacturing applications.

Drive Components

Including motors, gearboxes, and transmission elements. MAIKONG ensures all replacement parts meet rigorous quality standards for the demanding Philippine industrial environment.

Success Stories: Plastic Shredder Implementation in Philippine Industries

Discover how Philippine businesses have successfully implemented MAIKONG plastic shredders to transform their waste management approach and improve their bottom line.

Case Study: Manila Packaging Manufacturer

Challenge:

A leading packaging manufacturer in Manila was generating over 500kg of plastic scrap daily from production processes. Disposal costs were increasing, and valuable material was being wasted.

Solution:

Implementation of a MAIKONG industrial plastic shredder with a specialized feeding system for handling mixed packaging waste, including films and rigid containers.

Results:

- 70% reduction in waste disposal costs

- Recovery of approximately 450kg of recyclable material daily

- ROI achieved within 11 months

- Improved sustainability metrics for corporate reporting

Case Study: Cebu Injection Molding Facility

Challenge:

A medium-sized injection molding company in Cebu was struggling with managing start-up lumps, runners, and rejected parts. Limited floor space presented an additional challenge.

Solution:

Installation of a compact MAIKONG small plastic shredder with specialized blades for processing hard plastic parts and a space-efficient design.

Results:

- In-house recycling of 200kg of plastic waste weekly

- Material recovery value of approximately ₱30,000 monthly

- 50% reduction in virgin material purchases

- Minimal floor space requirement (3m²)

MAIKONG Plastic Shredder Technical Specifications

MAIKONG offers a comprehensive range of plastic shredder models to meet the diverse needs of Philippine industries. Below are the technical specifications for our most popular models:

| Model |

Blade Diameter |

Motor Power |

Processing Capacity |

Dimensions (L×W×H) |

Ideal Application |

| MAIKONG-600 |

220mm |

11kW×2-15kW×2 |

100-200 kg/h |

2500×1100×1600mm |

Small manufacturing, laboratories |

| MAIKONG-800 |

300mm |

18.5kW×2-22kW×2 |

300-500 kg/h |

3000×1400×1800mm |

Medium production facilities |

| MAIKONG-1000 |

400mm |

45kW×2 |

500-800 kg/h |

3900×1800×2200mm |

Large manufacturing plants |

| MAIKONG-1200 |

400mm |

45kW×2 |

800-1200 kg/h |

4100×1800×2300mm |

Recycling facilities |

| MAIKONG-1600 |

500mm |

75kW×2 |

1500-2000 kg/h |

5400×2400×2600mm |

Industrial recycling operations |

Note: All MAIKONG plastic shredder models can be customized with various blade configurations, feeding systems, and output options to meet specific requirements. Contact our technical team for detailed specifications and customization options.

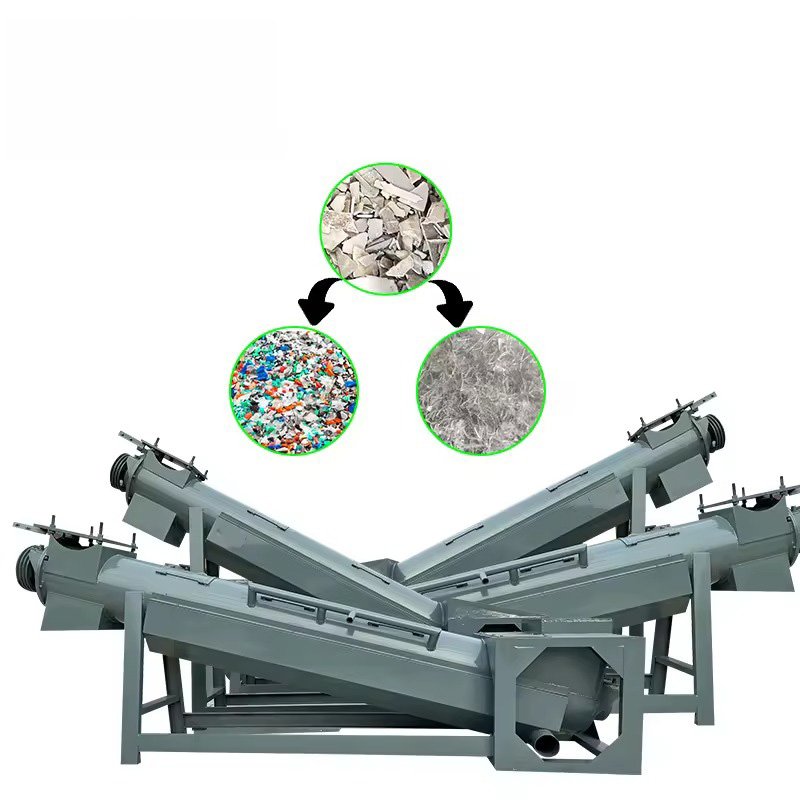

Customization Options for Your Plastic Shredder

MAIKONG understands that Philippine industries have unique requirements. We offer extensive customization options to ensure your plastic shredder perfectly matches your operational needs.

Input Systems

- Conveyor Feeding: Automated material infeed via belt or screw conveyor

- Inclined Chutes: Facilitates forklift or crane loading

- Hopper Designs: Specialized for different material types

- Vertical Pusher: Force-feeds materials against the rotor

Output Collection

- Cyclone Collection: Air-driven material transport

- Belt Conveyors: For continuous output handling

- Screw Conveyors: For controlled material movement

- Bagging Systems: For direct packaging of output

Specialized Components

- Rotor Types: Specialized for films, rigid materials, or mixed waste

- Motor Options: Increased power or hydraulic drive systems

- Elevated Racks: For integration with other equipment

- Safety Enhancements: Additional protective features

Need a Custom Solution?

MAIKONG engineers can design a tailored plastic shredder solution specific to your Philippine operation’s unique requirements.

Request Custom Solution

Frequently Asked Questions About Plastic Shredders

What types of plastic can MAIKONG shredders process?

MAIKONG plastic shredders are designed to handle a wide range of plastics common in Philippine industries, including PET, HDPE, PVC, LDPE, PP, and PS. Our machines can be configured with specific blade types and cutting chambers optimized for particular plastic materials, from soft films to rigid containers and pipes.

How much maintenance does a plastic shredder require?

Maintenance requirements depend on usage intensity and material types. Typically, MAIKONG shredders require blade inspection every 80-100 operating hours, with rotation or replacement as needed. Regular lubrication and cleaning are also essential. Our machines are designed for easy maintenance access, and we provide comprehensive maintenance schedules and training for Philippine customers.

What is the typical return on investment for a plastic shredder?

ROI varies based on waste volume, disposal costs, and material value. Most Philippine businesses achieve ROI within 12-24 months through reduced disposal costs, material recovery value, and decreased virgin material purchases. MAIKONG provides detailed ROI calculations during the consultation process to help you understand the financial benefits specific to your operation.

Can MAIKONG provide local support in the Philippines?

Yes, MAIKONG maintains a network of distributors and service technicians throughout the Philippines to provide prompt installation, training, and maintenance support. We also offer remote diagnostics and 24/7 technical assistance to ensure minimal downtime for your operation.

How do I determine the right size plastic shredder for my needs?

Sizing depends on several factors, including daily waste volume, material type, available space, and processing goals. MAIKONG consultants work with Philippine businesses to analyze these factors and recommend appropriately sized equipment. We typically suggest selecting a shredder with 20-30% more capacity than your current needs to accommodate future growth.

Conclusion: Transforming Philippine Industries with MAIKONG Plastic Shredders

As plastic waste management becomes increasingly critical for Philippine industries, implementing effective recycling solutions is no longer optional—it’s essential for sustainable business operations. MAIKONG plastic shredders offer a proven, efficient way to transform waste challenges into opportunities.

By investing in a quality plastic shredder, Philippine businesses can reduce disposal costs, recover valuable materials, meet environmental regulations, and contribute to a more sustainable future. MAIKONG’s comprehensive range of shredding solutions—from mini plastic shredder machines to robust industrial plastic shredders—ensures that businesses of all sizes can find the perfect fit for their specific needs.

Take the first step toward optimized plastic waste management today. Contact MAIKONG to discuss how our industry-leading plastic shredder technology can transform your operation and boost your bottom line.

Ready to Transform Your Plastic Waste Management?

Contact MAIKONG today to discuss your specific requirements and discover the perfect plastic shredding solution for your Philippine business.

Contact Us Today