In today’s environmentally conscious world, managing plastic waste has become a critical challenge for businesses across the Philippines. From small manufacturing facilities to community recycling initiatives, the need for efficient, space-saving solutions has never been greater. MAIKONG’s small plastic waste shredder systems offer the perfect balance of performance, affordability, and sustainability for operations that don’t require industrial-scale equipment but still demand professional results.Whether you’re dealing with production scrap, post-consumer waste, or looking to establish a small recycling operation, our compact shredders provide the essential first step in the plastic recycling process. Let’s explore how these versatile machines can transform your waste management approach while contributing to a more sustainable future for the Philippines.

What is a Small Plastic Waste Shredder?

MAIKONG’s compact plastic shredder designed for small-scale operations

A small plastic waste shredder is a specialized machine designed to reduce various plastic materials into smaller, uniform pieces. Unlike their larger industrial counterparts, these compact units are specifically engineered for lower-volume applications while maintaining professional-grade performance. They serve as the critical first step in the plastic recycling chain, preparing materials for further processing through granulation, melting, or other recycling methods.

MAIKONG’s small shredders feature a precision-engineered cutting system with a rotor equipped with hardened steel blades that rotate against fixed counter-blades. This creates a powerful shearing action that efficiently cuts through various plastic materials. The resulting shredded pieces typically range from 10-20mm in size, making them ideal for subsequent recycling processes.

These machines are distinguished by their compact footprint, reduced power requirements, and optimized performance for small to medium throughput applications. While industrial shredders might process tons per hour, our small plastic waste shredder models are perfect for operations processing up to several hundred kilograms per day – ideal for the diverse needs of Philippine businesses.

Key Advantages for Philippine Businesses

Benefits of Small Plastic Shredders

- Significant waste volume reduction (up to 80%)

- Lower transportation costs for waste disposal

- On-site recycling capabilities for production scrap

- Reduced dependency on virgin plastic materials

- Smaller footprint ideal for limited space facilities

- Lower power consumption compared to industrial models

- Contribution to corporate sustainability goals

- Potential new revenue stream from recycled materials

Limitations to Consider

- Lower throughput than industrial models

- May require pre-cutting of very large items

- Not suitable for extremely high-volume operations

- Requires regular blade maintenance for optimal performance

For Philippine businesses, particularly small to medium enterprises, a small plastic shredder offers an accessible entry point into plastic recycling. By processing materials on-site, companies can transform waste management from a cost center into a potential revenue source while simultaneously reducing their environmental footprint.

Ready to Reduce Your Plastic Waste?

Discover how MAIKONG’s small plastic shredders can help your Philippine business save costs and improve sustainability.

Contact Us on WhatsApp

How It Works: Technology Explained

Cross-section view of MAIKONG’s shredding mechanism

MAIKONG’s small plastic waste shredder operates on a precision-engineered cutting principle that balances efficiency with reliability. Understanding the technology behind these machines helps appreciate their value in the recycling process:

Core Components

Feeding System

The process begins at the hopper – a specially designed intake chamber that guides plastic waste toward the cutting mechanism. Our hoppers are engineered with optimal angles to facilitate smooth material flow without jamming, even with irregularly shaped items.

Cutting Chamber

The heart of the small plastic shredder is its cutting chamber, where the actual size reduction occurs. This enclosed space houses the rotor and blade system while containing the material during processing.

Rotor and Blade System

Our shredders employ a low-speed, high-torque rotor equipped with hardened steel blades. These rotating blades work against fixed counter-blades to create a powerful shearing action. This design maximizes cutting efficiency while minimizing wear and energy consumption.

Sizing Screen

A perforated screen beneath the cutting chamber determines the final particle size. Material continues to be processed until it’s small enough to pass through these openings, ensuring consistent output size.

The Shredding Process

- Plastic waste is loaded into the hopper at the top of the machine.

- Gravity feeds the material into the cutting chamber.

- The rotating blades catch the material and force it against the fixed blades, creating a shearing action.

- This cutting process continues until the pieces are small enough to pass through the sizing screen.

- The uniformly sized output material exits through the discharge area, ready for collection or further processing.

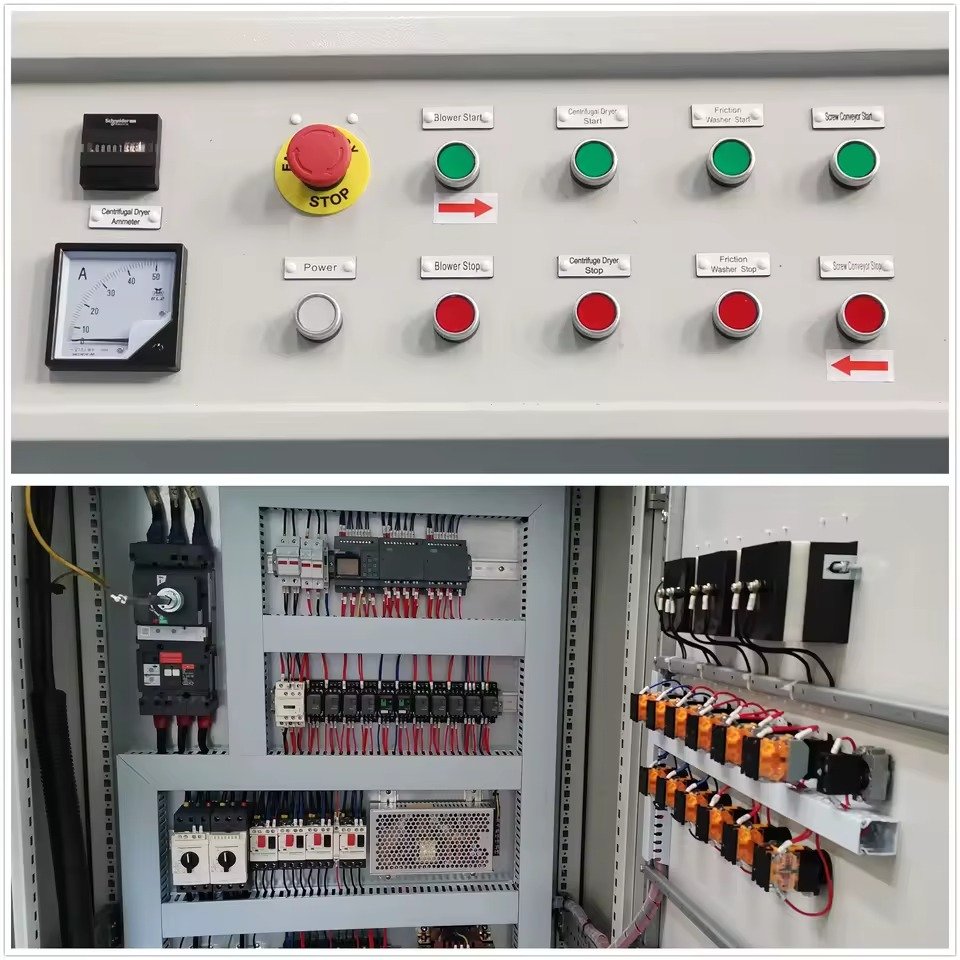

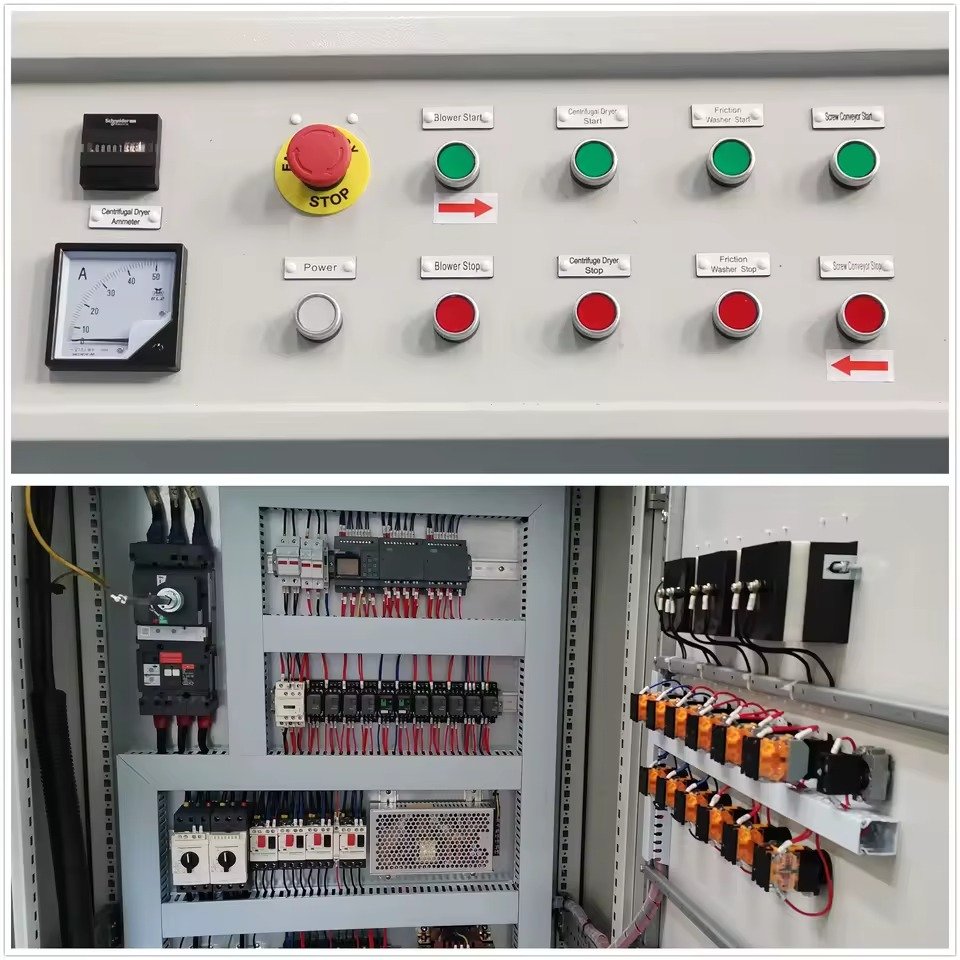

Control Systems

MAIKONG’s small shredders feature intelligent control systems that monitor operation and provide safety features. These include automatic reverse function for handling jams, overload protection to prevent motor damage, and emergency stop capabilities. Depending on the model, our machines may use Siemens, ABB, or other quality components to ensure reliable performance.

Applications and Materials Processed

Before and after: Plastic waste transformed by MAIKONG’s shredder

The versatility of MAIKONG’s small plastic waste shredder makes it suitable for numerous applications across different industries in the Philippines. These compact machines can process a wide range of plastic materials, making them invaluable for various recycling operations.

Common Materials Processed

| Plastic Type |

Examples |

Recyclability |

| PET (#1) |

Bottles, food containers |

Excellent |

| HDPE (#2) |

Buckets, crates, bottles |

Excellent |

| PVC (#3) |

Pipes, profiles, sheets |

Good |

| LDPE (#4) |

Films, bags, flexible packaging |

Good |

| PP (#5) |

Containers, caps, industrial parts |

Excellent |

| PS (#6) |

Packaging, disposable items |

Moderate |

Key Applications

Manufacturing Scrap Recovery

Process production waste like runners, sprues, rejected parts, and purges from injection molding, extrusion, or thermoforming operations. Convert this waste back into usable regrind material.

Post-Consumer Recycling

Shred collected consumer plastic waste such as bottles, containers, and packaging for further recycling processes or volume reduction before transport.

Small Recycling Operations

Ideal for community recycling initiatives, small recycling businesses, or educational institutions teaching sustainable practices in the Philippines.

MAIKONG shredder in action at a Philippine recycling facility

MAIKONG Small Shredder Models & Specifications

MAIKONG offers several small plastic waste shredder models to accommodate different operational needs and budgets. Our compact shredders deliver professional performance while maintaining a small footprint ideal for Philippine businesses with space constraints.

| Model |

Blade Diameter |

Motor Power |

Dimensions (L×W×H) |

Capacity |

| MK-600 |

220mm |

11kW×2 |

2500×1100×1600mm |

100-150 kg/hr |

| MK-800S |

300mm |

18.5kW×2 |

3000×1400×1800mm |

200-250 kg/hr |

| MK-800M |

400mm |

37kW×2 |

3700×1800×2200mm |

300-400 kg/hr |

MAIKONG’s range of small plastic shredder models

Featured Model: MK-600 Mini Plastic Shredder

Our most compact offering, the MK-600 is perfect for smaller operations with limited space and power availability. Despite its small size, it delivers impressive performance for processing a wide range of plastic materials.

- Dual 11kW motors for reliable operation

- Hardened steel blades for extended service life

- Compact footprint ideal for tight spaces

- Low noise operation suitable for indoor use

- PLC control system with automatic reverse function

The MK-600 is particularly popular among small manufacturing operations in the Philippines looking to recycle their production scrap efficiently.

The compact MK-600 mini plastic shredder

Find Your Ideal Shredder Model

Not sure which model best fits your needs? Our experts can help you select the perfect solution for your specific application.

Email for Expert Advice

Choosing the Right Small Shredder

Selecting the optimal small plastic waste shredder for your Philippine business requires consideration of several key factors. Our team at MAIKONG can guide you through this process, but understanding these basics will help you make an informed decision:

Material Type

Different plastics have varying properties that affect shredding. Soft films require different blade configurations than rigid containers. Consider what materials you’ll primarily process.

Volume Requirements

Estimate your daily or weekly processing needs in kilograms. This helps determine the appropriate machine capacity to avoid bottlenecks in your operation.

Space Constraints

Measure your available floor space and access points. Our compact models are designed for small facilities but still require adequate space for operation and maintenance.

Power Availability

Check your electrical infrastructure to ensure compatibility with the shredder’s power requirements. Some facilities may need electrical upgrades for larger models.

Noise Considerations

If operating in mixed-use spaces, noise levels become important. Our smaller models feature noise reduction design but still generate some operational sound.

Budget Constraints

Balance initial investment against long-term value. Sometimes a slightly larger model offers significantly better return on investment through increased throughput.

Small vs. Mini Plastic Shredder: Understanding the Difference

Comparing MAIKONG’s small and mini plastic shredder options

MAIKONG offers both small plastic shredder and mini plastic shredder machine options. Understanding the distinction helps in selecting the right equipment:

| Feature |

Mini Plastic Shredder |

Small Plastic Shredder |

| Typical Capacity |

50-150 kg/hr |

150-400 kg/hr |

| Power Requirements |

5-15 kW |

15-40 kW |

| Footprint |

Very compact |

Compact |

| Ideal For |

Very small operations, startups |

Small to medium businesses |

| Material Handling |

Smaller, softer items |

Wider range of materials |

Customization and Add-ons

MAIKONG’s small plastic waste shredder systems can be tailored to meet your specific operational requirements. These customization options enhance functionality, efficiency, and integration with your existing processes.

Conveyor Feed System

Conveyor Feed System

Cyclone Collection

Cyclone Collection

Film Specialist Rotor

Film Specialist Rotor

Popular Customization Options

Material Handling Systems

- Infeed conveyors for continuous operation

- Screw conveyors for controlled feeding

- Inclined chutes for forklift or crane loading

Output Collection Systems

- Cyclone collectors for dust-free operation

- Output conveyors for direct transfer

- Bagging systems for easy material handling

Specialized Components

- Film-specific rotors for flexible materials

- Heavy-duty rotors for challenging materials

- Custom screen sizes for specific output requirements

Installation Options

- Elevated racks for integration with other equipment

- Mobile bases for facility flexibility

- Sound enclosures for noise-sensitive environments

Custom Solutions for Philippine Businesses: MAIKONG understands the unique challenges faced by recycling operations in the Philippines. Our engineering team can develop customized solutions to address specific requirements, space constraints, or integration needs for your facility.

Maintenance and Spare Parts

Proper maintenance is essential for maximizing the lifespan and performance of your small plastic waste shredder. MAIKONG designs our machines with serviceability in mind, featuring accessible components and detachable cutting heads for easier maintenance.

Regular maintenance ensures optimal shredder performance

Recommended Maintenance Schedule

| Interval |

Maintenance Task |

Importance |

| Daily |

Visual inspection and cleaning |

Essential |

| Weekly |

Blade gap inspection |

High |

| Monthly |

Lubrication of bearings |

High |

| Quarterly |

Blade rotation or replacement |

Critical |

| Bi-annually |

Full mechanical inspection |

Essential |

Quality Plastic Shredder Parts

MAIKONG provides genuine replacement parts specifically engineered for our machines. Using original plastic shredder parts ensures optimal performance and longevity. Our most commonly replaced components include:

- Cutting blades and counter-blades

- Blade spacers and mounting hardware

- Screens and perforated plates

- Bearings and seals

- Drive belts and pulleys

- Motor brushes and electrical components

- Hydraulic components (where applicable)

- Control system parts

Maintenance Support: MAIKONG offers comprehensive maintenance support for customers in the Philippines, including remote troubleshooting, maintenance training, and expedited parts delivery. Contact our service team for assistance with your small plastic waste shredder.

For detailed information about available replacement parts for your specific model, visit our plastic shredder parts page or contact our service department directly.

Why Choose MAIKONG?

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

When investing in a small plastic waste shredder, choosing the right manufacturer is as important as selecting the right machine. MAIKONG has established itself as a trusted partner for recycling equipment throughout the Philippines and across Asia.

Engineering Excellence

Our engineering team combines decades of experience with continuous innovation. Every MAIKONG shredder undergoes rigorous design optimization and testing to ensure performance and reliability in real-world conditions.

Quality Manufacturing

All MAIKONG equipment is produced in our modern facility in GD, SZ using premium materials and components. Our quality control processes ensure every machine meets our exacting standards before shipment.

Local Support

We maintain a strong presence in the Philippines with local representatives who understand the unique challenges of the market. This ensures prompt support, service, and parts availability for all our customers.

Complete Recycling Solutions

Beyond our small plastic waste shredder line, MAIKONG offers a comprehensive range of recycling equipment to meet diverse needs:

4.8

Customer Satisfaction

After-Sales Support

4.7/5

Frequently Asked Questions

What is the average ROI period for a small plastic waste shredder?

Most Philippine businesses achieve return on investment within 6-18 months, depending on operation scale, material type, and current waste disposal costs. Facilities processing high-value plastics or paying premium disposal fees typically see faster returns. MAIKONG can help calculate your specific ROI based on your operation details.

What power requirements do your small shredders have?

Our small plastic waste shredder models typically require three-phase power ranging from 11kW to 37kW depending on the specific model. We can provide detailed electrical specifications to ensure compatibility with your facility’s infrastructure. Some models can be configured for different voltage requirements common in the Philippines.

How loud are MAIKONG’s small plastic shredders?

Our small shredders typically operate between 75-85 dB during normal operation, comparable to a vacuum cleaner or busy restaurant. The low-speed, high-torque design produces less noise than high-speed alternatives. Optional sound enclosures can further reduce noise levels for sensitive environments.

What maintenance is required for optimal performance?

Regular maintenance includes daily cleaning, weekly inspection of blade gaps, monthly lubrication, and quarterly blade rotation or replacement depending on usage. Our machines are designed for easy maintenance with accessible components and detachable cutting heads. MAIKONG provides comprehensive maintenance documentation and training.

Do you provide installation and training services in the Philippines?

Yes, MAIKONG offers complete installation, commissioning, and operator training services throughout the Philippines. Our experienced technicians ensure your equipment is properly installed and your team is thoroughly trained on operation, maintenance, and safety procedures. We also provide ongoing technical support via phone, email, and on-site visits when needed.

Transform Your Plastic Waste Management Today

Investing in a MAIKONG small plastic waste shredder offers Philippine businesses an efficient, cost-effective solution for managing plastic waste while contributing to environmental sustainability. Our compact, reliable machines provide the perfect entry point into plastic recycling without requiring the space or investment of industrial-scale equipment.

From manufacturing facilities looking to recycle production scrap to small recycling operations processing post-consumer waste, our shredders deliver consistent performance and value. With local support, quality engineering, and a range of customization options, MAIKONG is your trusted partner for plastic recycling equipment in the Philippines.

Ready to Discuss Your Plastic Recycling Needs?

Contact MAIKONG today to speak with our experts about finding the perfect small plastic waste shredder for your operation.

Visit our website: https://plasticshredder.ph

Learn more about MAIKONG: About Us

Conveyor Feed System

Conveyor Feed System Cyclone Collection

Cyclone Collection Film Specialist Rotor

Film Specialist Rotor